Sarah Baker (14-ERD-010)

Abstract

Most chemical reactions of interest for clean energy, such as the conversion of sunlight to chemical energy and the transfer of carbon dioxide into and out of solution, are routinely carried out in nature. Conventional industrial approaches to catalyze these reactions are either inefficient or have yet to be developed. Certain enzymes have been identified that carry out these reactions under mild conditions, which presents an opportunity for biocatalysis (the use of natural catalysts such as protein enzymes to chemically transform organic compounds) and biomimetics (the application of designs from nature to solve problems in engineering, materials science, medicine, and other fields) to fill the gap between available technologies and natural processes. Enzyme biocatalysis is currently limited primarily to low-volume, high-value products such as pharmaceuticals because of the narrow operating parameters required to preserve biocatalyst activity, slow rates of throughput from low catalyst loading, and limited mass transfer and susceptibility to contamination and poisoning. However, the ability to generate functional molecules or cells of interest now enables synthesis of engineered enzymes that are more amenable to industrial processes, widening the available operating parameters. These enzymes must be integrated with functional materials to fully realize their potential in large-scale chemical processes. Using cellular microstructural design strategies as inspiration, we will develop a new class of gas-to-liquid bioreactors based on enzyme-embedded, nanometer- and micrometer-structured polymeric materials.

The enzyme-embedded, high-permeability, polymer-based reactor components we propose will permit new uses of biocatalysis for energy applications. These tunable, modular reactor components will incorporate engineered properties at multiple size scales using advanced manufacturing techniques. Inspired by the hierarchical structures of living systems, the components will enable efficient use of enzymatic reactions without the drawbacks of living-cell fermentation. The ability to additively manufacture high-throughput bioreactors will enable new large-scale systems such as those that will be required for creation of designer liquid fuels from methane. Successful implementation of this technology could offset the methane leaks associated with shale gas production, improving the case for shale gas as a major domestic energy source.

Mission Relevance

This project will further the Laboratory's expertise in the strategic focus area of energy and climate security relevant to delivering innovative manufactured materials for gas-to-liquid conversion. The project will develop the capability to generate a new class of engineered and manufactured materials to support biocatalysis for energy applications, in support of the core competency in bioscience and bioengineering.FY15 Accomplishments and Results

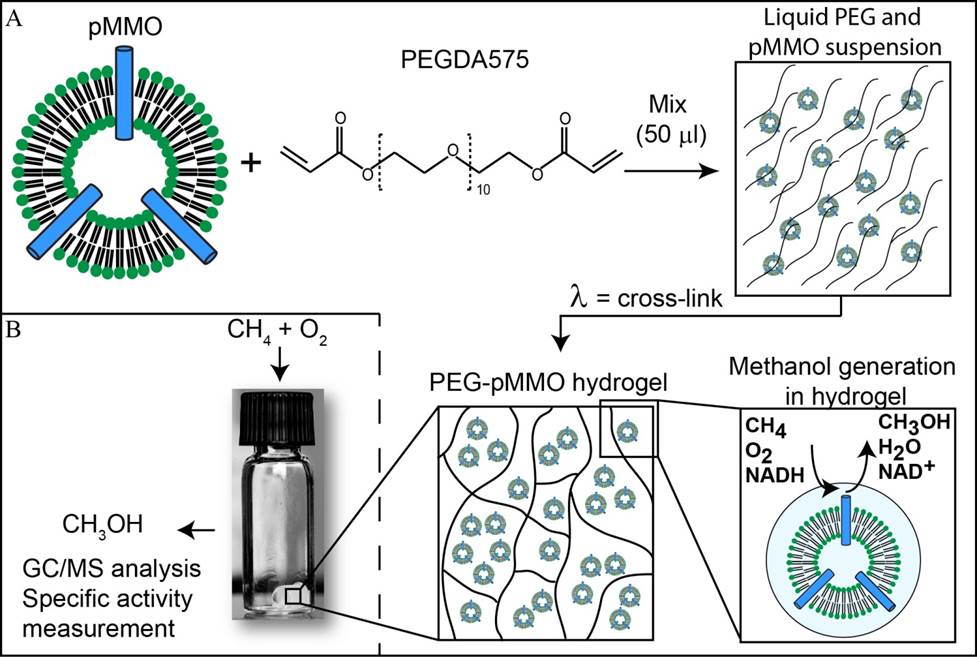

In FY15 we (1) identified the highest-risk challenge to our technique for converting methane to methanol as maintaining the activity of the enzyme pMMO (particulate methane monooxygenase, which can oxidize the carbon–hydrogen bond in methane) inside a polymer; (2) demonstrated pMMO activity in PEGDA (polyethylene glycol-diacrylate, a polymeric hydrogel used in designed biomaterials) of varying concentrations and molecular weights; (3) developed a simple, scalable process for stabilizing pMMO in liposomes (spherical vesicles with a lipid bilayer), and for incorporating liposomes or crude cell-membrane preparations of pMMO into PEGDA; and (4) tested up to six conversion cycles, observing that the polymer-embedded enzyme routinely achieves two-thirds of the activity of the free enzyme, but can be easily removed from solution and reused, ultimately leading to far more methanol production per enzyme.Publications and Presentations

- Baker, S. E., et al., Biocatalytic polymer materials for partial oxidation of methane to methanol. 249th American Chemical Society National Mtg. and Expo., Denver, CO, Mar. 22–26, 2015. LLNL-PRES-668366-DRAFT.

- Baker, S. E., et al., Printable, biocatalytic polymer materials for partial oxidation of methane to methanol. 2015 MRS Fall Mtg. and Exhibit, Boston, MA, Nov. 29–Dec. 4, 2015. LLNL-ABS-676428.