Juergen Biener (15-ERD-019)

Abstract

Multiscale porous materials with tailored density, morphology, and composition have recently attracted interest in the material science community because of their many promising applications ranging from high-energy-density physics and shock absorption to catalysis and energy storage and conversion. However, despite the progress that has been made in nanometer-scale materials synthesis and in the field of engineered microscopic lattices, there still remains a length-scale gap that separates true nanomaterials from engineered microstructures, thus preventing us from taking full advantage of the potential of these multiscale materials. We are attempting to bridge this gap by combining additive manufacturing technologies with nature's principles of self-organization, self-assembly, and template capability. Specifically, we hope to enable development and tooling-free integration of monolithic, low-density porous carbons with submicron feature size, tailored anisotropic morphologies, and uniaxial density gradients. We will integrate LLNL's additive manufacturing technologies and nanometer-scale materials synthesis capabilities, which have the potential to improve the reproducibility of high-energy-density and Inertial Confinement Fusion target fabrication, as well as enable new concepts for mitigating hydrodynamic-instability growth in laser Inertial Confinement Fusion.

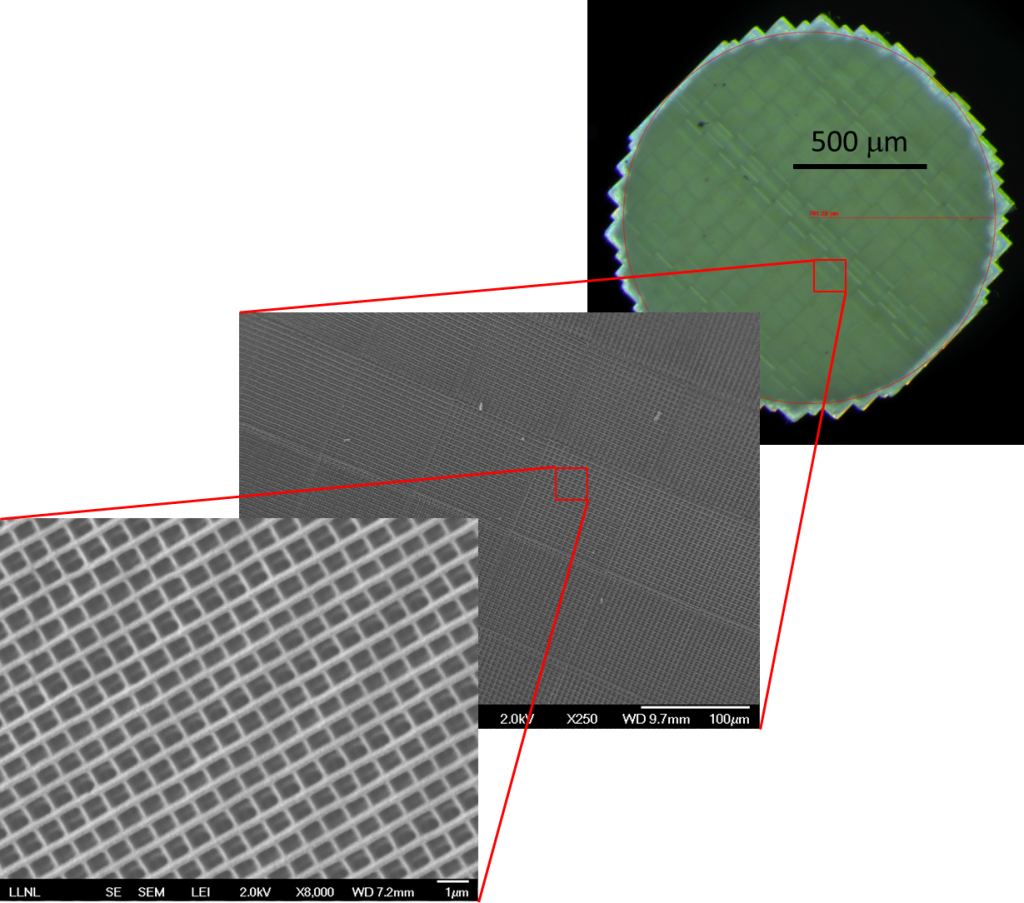

If successful, we will develop monolithic millimeter-sized, graded low-density carbon-based foam materials with submicron feature size (see figure) that offer deterministic control over uniaxial density profiles where the density changes by a factor of ten. We expect to achieve submicron resolution, improving the resolution of existing additive manufacturing technologies as well as integrating emerging, high-resolution technologies. In addition, we will develop tailored additive manufacturing feedstock materials with built-in porosity and length-scale control, as well as integrate template approaches. Our research has the potential to greatly improve the reproducibility of laser fusion-target fabrication, provide new concepts for mitigating hydrodynamic-instability growth for fusion targets, and reduce the time associated with the development cycle for these targets. The proposed new materials capability also has the potential to create a pathway towards porous structures that mimic nature's functional filtration organs such as the kidney and liver, as well as enable new energy storage and conversion concepts.

Mission Relevance

Monolithic multiscale porous materials with tailored mass transport properties are the future of high-energy-density physics target fabrication and are expected to enable transformational large-scale electrical energy storage solutions. Our research project to integrate additive manufacturing technologies and nanometer-scale materials synthesis capabilities is well aligned with Livermore's core competency in advanced materials and manufacturing. In addition, the research supports the scientific needs of the Laboratory's stockpile stewardship science and energy and climate security strategic focus areas.

FY15 Accomplishments and Results

For FY15 we (1) began evaluation of the resolution limit of LLNL's projection micro-stereolithography system and demonstrated submicron resolution for the depth of a three-dimensional object, and ordered higher-resolution optics for submicron resolution along the horizontal and vertical axes; (2) developed and tested a gyroid structure (minimal surface area); (3) selected projection micro-stereolithography and the Nanoscribe high-resolution three-dimensional printer as the most promising technologies for our additive manufacturing of submicron structures; (4) procured and installed a Nanoscribe system and performed first tests on submicron porous structures; (5) began development of a new block-copolymer photoresist material, and (6) began development of target designs for testing graded-density reservoirs in planar geometries on the OMEGA Laser Facility at the Laboratory for Laser Energetics in New York, and submitted a shot proposal for the first quarter of FY16.