Alexander Gash (16-ERD-040)

Executive Summary

We are developing novel fabrication techniques and using dynamic characterization and modeling to capture the unique behavior associated with microscopically designed high-explosive materials. Our research effort will contribute to the first-principles understanding of energetic materials and insensitive high explosives, and enable innovative concepts for surety for stockpile modernization and provide novel energetic material solutions to issues relevant to conventional defense.

Project Description

The most important property of high explosives is the ability to detonate. Detonation waves are well known to propagate in a highly repeatable fashion, converting chemical energy into usable mechanical and thermal energy. Currently, modern high-explosives development focuses on designing and synthesizing new molecules with improved performance or energy density. However, the cycle from discovery to application can take many years because of a variety of constraints such as safety, scaling, and cost. It is imperative that we seek alternate routes for improving the safety and performance of our current high-explosives materials to keep pace with the ever-changing and rapidly advancing threats to our national security. There have been significant advancements in manufacturing materials such that it is now feasible to engineer the microscopic structure, or architecture, of a high-explosives part. It is now possible to spatially distribute two or more materials within a three-dimensional object and place them with submillimeter to micrometer-scale spatial resolution. Because the size and orientation of these features can now be placed on a length scale commensurate with the scale of governing dynamic phenomena, we hypothesize that this creates new possibilities for modulating the safety and performance of high-explosives systems through architectural design. We therefore plan to simultaneously develop novel fabrication techniques and use dynamic characterization and modeling to capture the unique behavior associated with microscopically designed high-explosive materials. Through characterization and modeling of these novel material structures, we intend to understand, quantify, and model the fundamental effects of high-explosives micro-structural architecture on dynamic response, including both intrinsic and extrinsic phenomena. Specifically, how and to what extent does the architectural length translate into dynamic features as a detonation wave passes (intrinsic effects), and can the architecture be used to focus or defocus the transport of particles via complex interactions during the dynamic event (extrinsic effects). We will examine whether modeling can be used to inform the experimental designs, and what advancements in multiple-scale modeling are required to improve accuracy.

We plan to conduct dynamic imaging experiments to validate and improve simulations of high-explosives detonation. For the first time, we will explore the critical importance of the location, geometry, composition, and interfacial contact between materials in highly engineered high-explosives articles. The spatial resolution of this contact architecture has been limited by traditional processing methods, and therefore has been relatively coarse in current application components. With the successful application of layer-by-layer additive manufacturing of high explosives at Livermore, there now exists the promising opportunity to shrink the high-explosives architectural scale by up to two orders of magnitude. The goal of our effort is to understand the fundamental role that micro-architecture has on the dynamic characteristics of high explosives. This requires a comprehensive and coordinated research effort, which will include state-of-the-art additive manufacturing, dynamic diagnostic techniques, and high-explosives modeling. Furthermore, we will examine modulations in the composition of the high-explosives microstructure at several length scales with the goal of understanding the parameter scaling between such features, and intrinsic detonation properties such as overall detonation velocity and wave shape. We expect our research effort will contribute to the first-principles understanding of energetic materials and insensitive high explosives, and enable innovative concepts for surety for stockpile modernization. In addition, it will provide novel energetic material solutions to issues relevant to conventional defense, and enable novel materials and understanding of performance–structure relationships.

Mission Relevance

A detailed understanding of new material architectures for high explosives will enable innovative component design to enhance the performance, safety, and precision of the nation's nuclear and conventional stockpile. This research supports NNSA goals in nuclear weapons stockpile management and addresses other national security missions. This effort, therefore, is well aligned with the priorities of the Laboratory's expertise in physics, chemistry, and material science of high explosives, as well as the core competency in advanced materials and manufacturing.

FY17 Accomplishments and Results

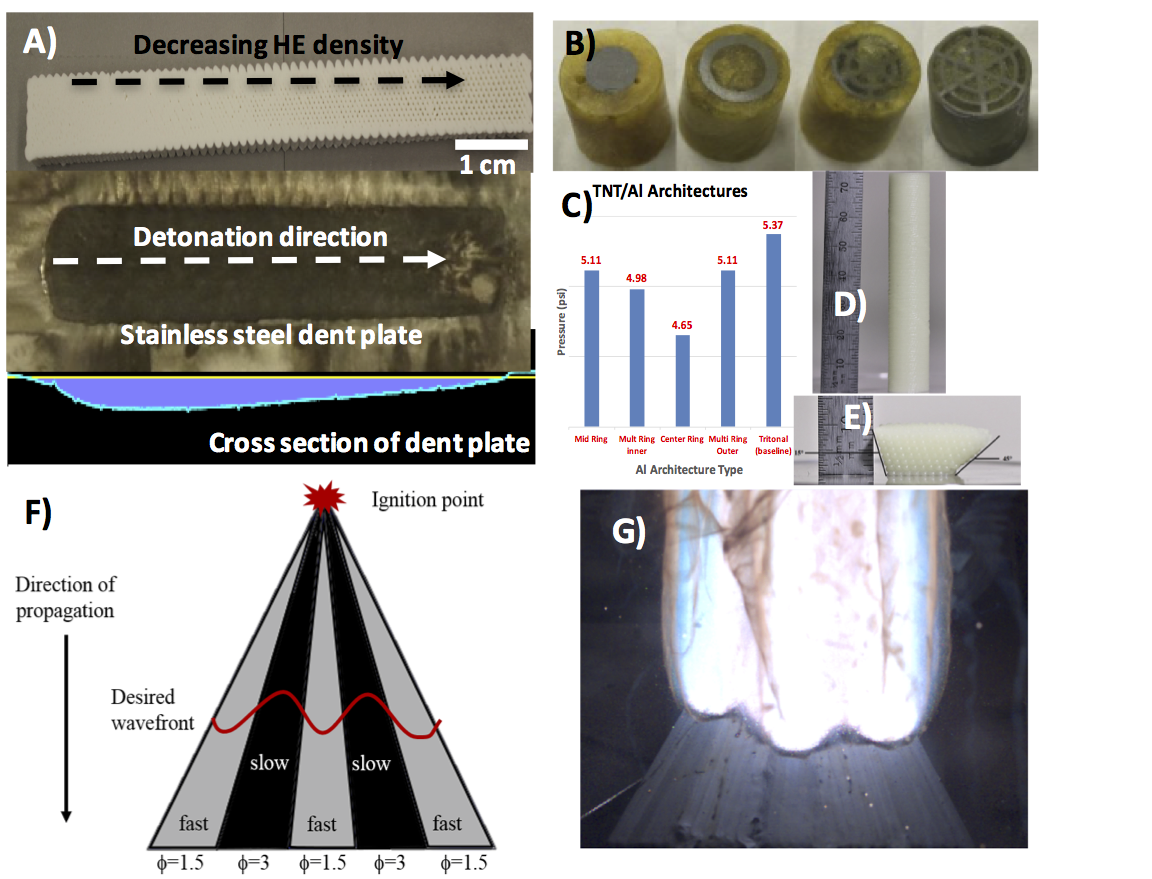

In FY17 we (1) fabricated additively manufactured high-explosive and aluminum composite structures and characterized the blast performance of these new materials with our academic collaborators; (2) developed a new additively manufactured high-explosive feedstock ink that contains TATB (triamino-trinitrobenzene, an insensitive high-explosive material); (3) successfully printed and tested additively manufactured composites that contain multiple high explosives; (4) created a machine control program and physical methods specific for improved high-explosives print-part quality; and (5) demonstrated control over detonation velocity and metal pushing using graded-density additively manufactured high-explosives parts.

With these milestones researchers can now vary and optimize the size, density, and volume fraction of mixtures of energetic materials, macropores, and inert or reactive additives to engineer and potentially optimize performance and safety characteristics of additively manufactured energetics. Through precise manipulation of the energetic architecture, additive manufacturing provides an excellent platform to rapidly test the effect of architecture on energetic materials properties, which will help ensure the safe and secure development of reliable and effective energetic materials for the NNSA and Department of Defense.

Publications and Presentations

Grapes, M. D., et al., 2017. "Direct Ink Write Fabrication and Testing of Explosive Lattice Structures with Engineered Density." Joint Army, Navy, NASA, Air Force 40th Propellant and Explosives Development and Characterization Subcommittee Meeting, Kansas City, MO, May 22–25, 2017. LLNL-PROC-729798.