Ryan Hurley (17-LW-009)

Executive Summary

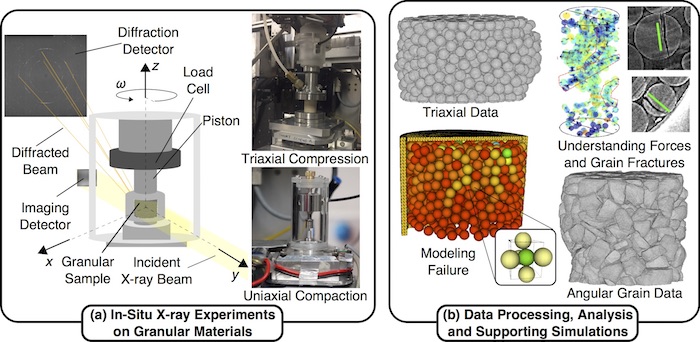

We are using x-ray imaging to understand force chains (and their failure mechanisms) in granular materials and applying these results to create complex computer codes to model the behavior of materials such as sands, soils, and powders. The resulting modeling capability supports the design of novel materials for energy- and defense-related missions.

Project Description

Granular materials (such as sands, soils, and powders) are ubiquitous in nature and used extensively in a variety of technologies. These materials play a pivotal role in processes ranging from energy harvesting to blast mitigation and possess similar collective behaviors to amorphous media such as emulsions, glasses, and cellular masses. Granular materials owe their mechanical properties of strength, ductility, and the ability to dissipate energy to both the filamentary, inter-particle contact networks (called "force chains") and the failure processes, such as grain fracture and deformation localization, that modify force chains. We need to understand grain-scale processes in granular and amorphous materials to build reliable numerical models. Until recently, imaging these features in situ during the loading and compaction of a bulk granular or amorphous material has been impossible, limiting our understanding of their role in furnishing mechanical properties. In this research, we are exploiting recent advances in x-ray imaging and numerical data-inversion techniques to study failure in granular materials with unprecedented detail, thus enhancing Lawrence Livermore National Laboratory's core modeling capabilities. In particular, we will use three-dimensional x-ray diffraction and x-ray computed tomography at the European Synchrotron Radiation Facility (ESRF) in Grenoble, France, to measure in situ strains and the kinematics of thousands of grains being loaded to failure. We will combine these measurements with novel data-inversion techniques to determine how inter-particle forces evolve during loading and failure. Through novel experiments, data analysis, and simulations, we will determine how properties of granular materials are related to failure processes, such as grain fracture and deformation localization, that modify force chains. In addition, we will enhance Livermore's grain-fracture code, GeodynL, in collaboration with researchers at the California Institute of Technology in Pasadena.

We expect to provide cutting-edge data on the behavior of granular materials during load and compaction, which will help enhance the numerical codes and constitutive laws used in modeling these processes. The results of this study will also elucidate aspects of materials science applicable to the broader class of amorphous materials that exist throughout nature, science, and technology. We intend to determine the force and strain conditions under which granular and amorphous materials mechanically fail, as well as determine how failures affect force chains (and vice versa), as well as material length scales, anisotropy, and strength. Finally, we will evaluate how well Livermore’s existing numerical models predict these processes. A successful project will offer new insight into the multi-scale nature of failure processes in granular materials. We will accomplish our goals by executing novel experiments on granular materials using triaxial compression of over 103 single-crystal ruby grains, and a quartz experiment (uniaxial or triaxial compression) that will notably involve nonspherical grains, to permit more complex stress-and-strain distributions within individual particles. Three-dimensional x-ray diffraction and x-ray computed tomography will image materials with unprecedented resolution. We will study grain strains, force networks, local failure processes, and the consequent changes in material length scales, anisotropy, and strength. Using this information, we will be able to assess and improve the Laboratory’s modeling capabilities for geological materials.

Mission Relevance

This research advances the DOE objective of delivering scientific discoveries and tools that transform our understanding of nature and strengthen the connection between advances in fundamental science and technology innovation. Insight gained from this work to elucidate the physics of granular and amorphous systems such as emulsions, glasses, and cellular masses, supports the Laboratory's core competency in Earth and atmospheric science. Modeling to improve the current understanding of failure processes in granular materials and using novel data-inversion techniques to provide new insight into multi-scale physics supports the Laboratory's core competency in high-performance computing, simulation, and data science.

FY17 Accomplishments and Results

In FY17, we (1) used 96 hours of beamtime at the ESRF for triaxial tests on sand; (2) collaborated with Dr. Hall of Lund University, Switzerland to develop triaxial cells for a custom load frame; (3) compressed angular sand samples to failure during 48 hours of beamtime at Cornell’s synchrotron (CHESS); (4) used preliminary data to study material properties and length scales in sand, and studied grain fracture and microstructure (which led to writing two papers currently in review); (5) debugged and enhanced GeodynL’s discrete element modeling (DEM) contact models, and compared GeodynL’s continuum damage-mechanics models for grain fracture and experiments; and (6) are currently testing ultrasound transmission in sand using tomography, producing data that will inform our FY18 synchrotron test.

Publications and Presentations

Hurley, R.C., et al. 2017a. "Force Measurements in Stiff, 3D, Opaque Granular Materials." EPJ Web of Conferences 140. 02006. doi: 10.1051/epjconf/201714002006. LLNL-CONF-707156.

——— 2017b. "Force Measurements in Stiff, 3D, Opaque Granular Materials." (poster) LLNL-POST-733123.

——— 2017c. "Investigating In Situ Failure in Granular Materials." LLNL-PRES-735664.

——— 2017d. "Linking Initial Microstructure and Local Response During Quasistatic Granular Compaction." Physics Review E 96. doi: 10.1103/PhysRevE.96.012905. LLNL-JRNL-725572.

——— 2017e. "Microstructure and Failure Analysis During Granular Compaction Using X-ray CT and 3D X-ray Diffraction." Third International Conference on Tomography of Materials and Structures, Lund, Sweden. LLNL-ABS-719811.

——— 2017f. "Microstructure and Failure Analysis During Granular Compaction Using X-ray Computed Tomography and 3D X-ray Diffraction." LLNL-PRES-733897.

——— 2017g. "Multi-Scale Mechanics of Granular Solids from Grain-Resolved X-Ray Measurements." Proceedings of the Royal Society of London A: Mathematical, Physical and Engineering Science. doi: 10.1098/rspa.2017.0491. LLNL-JRNL-719225.

——— 2017h. "Stress, Structure, and Force Measurements in Jammed 3D Granular Solids." LLNL-PRES-726862.

——— 2017i. "Understanding Mechanics and Stress Transmission in Granular Solids by Combining 3DXRD and XRCT." LLNL-PRES-732616.