Tommaso Pardini (15-LW-002)

Abstract

Use of x rays is an ideal way to characterize ultrafast processes in condensed matter systems because of their sensitivity to both the atomic and electronic structure of the material under study. Experimentally, such ultrafast dynamics are induced by an external perturbation in a process generally referred to as pumping. In today's experiments, pumping is achieved by illuminating the sample with short-pulsed lasers at optical wavelengths. This technique has several drawbacks including complicated absorption processes and vastly different penetration depths compared to the probing x rays. Ideally, both pumping and probing should be done at x-ray wavelengths. However, the technology to create two x-ray pulses with sufficient intensity and tunable delay time is still lacking. We plan to design, optimize, fabricate, and experimentally validate a multilayer mirror-based delay line for x rays (MEL-X) to allow, for the first time, high-intensity all-x-ray pump-and-probe experiments to be conducted at a free-electron laser facility. We will demonstrate this capability to study solid-to-liquid transitions in aluminum and silicon, leveraging our team's extensive experience in the field of x-ray optics and multilayer engineering for free-electron lasers and synchrotrons. We will demonstrate functionality of our proposed capability at a free-electron laser facility such as the Linac Coherent Light Source at the SLAC National Accelerator Laboratory in Menlo Park, California, where a substantial number of experiments require pump and probe.

Successful completion of our experimental campaign to validate a multilayer delay line for x rays at a free-electron laser beam line will shed light on the role of core electrons in the ultrafast melting of metals and semiconductors. We expect to split the high-intensity, ultrashort x-ray pulses from the Linac Coherent Light Source into a pump-and-probe beam, using the multilayer delay line. The delay between the two x-ray beams in the system will be obtained by adjusting the position of specific grazing-incidence mirrors, effectively altering the path difference between the two beams. The pump beam will isochorically heat nanometer-scale crystalline aluminum and silicon, initiating the melting process. With the probe beam, we will monitor the melting dynamic by recording on a charge-coupled device the intensity of multiple Bragg reflections as a function of delay time between pump and probe. The demonstration of a multilayer delay line for x-ray technology will benefit the scientific community by simplifying the experimental pump-and-probe setup and eliminating the need for complicated optical-laser integration schemes. In addition, it will facilitate understanding of experimental data given the well-understood processes governing x-ray interactions with matter. Finally, the development of our MEL-X and its application to the study of ultrafast melting in metals and semiconductors will fill a gap in the understanding of fast melting in materials, and its dependence on a particular electronic structure, which will advance our basic knowledge of ultrafast transitions.

Mission Relevance

A multilayer delay line for x-ray technology will benefit experiments in ultrafast transitions to warm dense matter, which are relevant to material behavior under extreme conditions, the understanding of planetary formation and composition, and high-energy-density science in general. This research, therefore, aligns well with the Laboratory's core competencies in advanced materials and manufacturing and high-energy-density science.

FY15 Accomplishments and Results

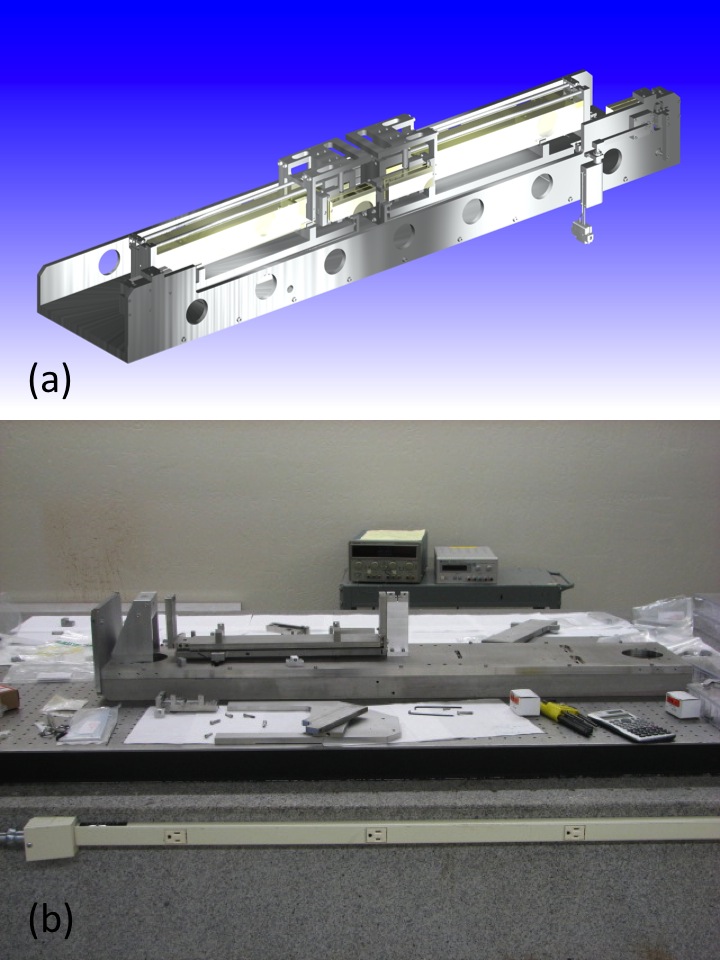

In FY15 we (1) completed the majority of engineering drawings for the delay line and started machining components, (2) tested the transport mechanism behind our x-ray delay line in a Livermore laboratory, (3) demonstrated that we can maintain the alignment of our mirrors to within half a micro-radian such that we can overlap the pump and probe beam to within few microns at the focal plane, and (4) began assembly of the delay line (see figure).

Publications and Presentations

- Pardini, T., et al., "The MEL-X project at the Lawrence Livermore National Laboratory: A mirror-based delay line for x-rays." Proc. SPIE 9589, 95890T-1 (2015). LLNL-PROC-676557.