Timofey Frolov (17-LW-012)

Executive Summary

This research uses atomistic simulations to provide details of material structures at interfaces, which strongly influence the mechanical, electronic, and optical properties of the materials. This work addresses the need to better understand the way phase behavior affects material properties and thereby predict the characteristics of new materials before their synthesis.

Project Description

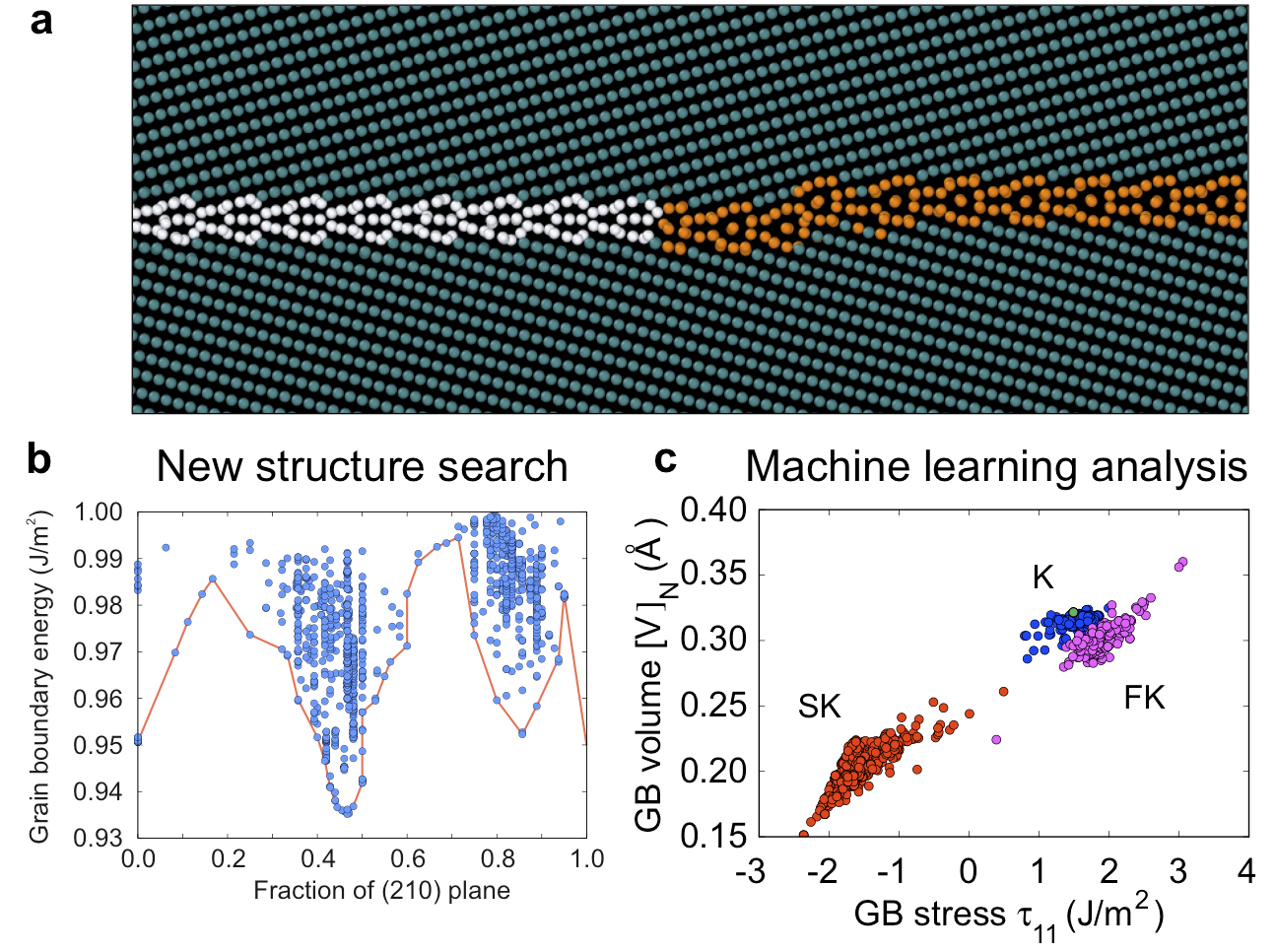

Complex grain microstructures emerge in many manufacturing processes, including additive manufacturing strategies that involve laser beam melting and subsequent rapid solidification of the added materials. Recent experimental evidence suggests that grain boundaries demonstrate the same properties as bulk materials, which is to say, they exhibit phase behavior: They exist in multiple states and show first-order transitions between them. The boundaries govern many properties of polycrystalline materials, including the vast majority of engineering materials. The occurrence of different grain boundary structures at elevated temperatures may explain the failure of previous modeling predictions. While the experimental investigation of the role of grain boundary phase transitions on material properties is currently a highly active field of research in the area of structural and functional materials, the atomic scale structure of these phases remains unknown. Atomistic computer simulations are designed to provide atomic-scale details of materials structure. However, their application to discover phase behavior of materials interfaces is challenged by the fact that no robust computational tool of interface-structure prediction exists at present. We are developing such a tool to demonstrate that interfaces exhibit phase behavior and strongly influence the mechanical, electronic, and optical properties of the materials. This tool addresses the need to predict the structure of material interfaces, so as to better understand the way phase behavior affects material properties and thereby predict the characteristics of new materials before their synthesis.

We expect to deliver the first, robust, publicly available tool to predict interface structure, and we will publish predictions for grain boundary structures using this newly developed tool. While the available state-of-the-art computational methodologies employed in interface modeling from the last four decades are incapable of finding the true ground state and all relevant metastable phases, our new computational tool will make predictions for new systems of high technological importance. To do this, we are expanding the predictive power of the Universal Structure Predictor: Evolutionary Xtallography (USPEX)—a tool developed at Stony Brook University in New York—to interfaces. This work includes determining and implementing structure search parameters and developing algorithms to identify grain boundary phases. After validating USPEX’s predictive capabilities, we will predict the phase behavior of ceramic grain boundaries. We expect that a large community of scientists in physics, chemistry, and materials science will use the tool; thus it will have a long-term impact on interface modeling and computer materials design. In addition, discovering the phase behavior of grain boundaries will generate new knowledge about fundamental properties of interfaces. Delivering these tools will give material scientists new capabilities to develop advanced metallic alloys and ceramics that can operate safely at high temperatures and in aggressive environments, properties that are essential to technologies for cleaner energy conversion and more efficient energy utilization.

Mission Relevance

This research supports the DOE objectives of delivering major scientific tools that strengthen the connection between advances in fundamental science and technology innovation and supporting a more economically competitive U.S. energy infrastructure. The proposed work will greatly strengthen Livermore's existing core competency in advanced materials and manufacturing by supporting continued development of continuum and mesoscale simulation methods to model phase, grain, and defect microstructure evolution. These models are designed to aid the rapid, cost-effective development of advanced materials and manufacturing processes. Our proposed work addresses the need for accurate prediction of interface structure and enables quantitative predictions of equilibrium and kinetic properties of interfaces, which is essential to enhance the predictive capabilities of mesoscale models. This capability also advances the Laboratory's core competency in high-performance computing, simulation, and data science.

FY17 Accomplishments and Results

We are developing a computational tool to predict interface structure. During this first year we've adapted USPEX’s evolutionary code to grain-boundary structure prediction. We (1) expanded the robustness of USPEX’s predictive power to interfaces; (2) determined structure search parameters and implemented them in USPEX, including grain translations and constraint searches at different densities; (3) developed algorithms to identify grain boundary phases; (4) validated USPEX predictive capabilities and generated new predictions in a model system with symmetric grain boundaries in Cu and W; (5) started working on binary systems and ceramic grain boundaries; (6) presented the results of our work in two invited talks at two different international conferences and one talk at a Laboratory seminar; and (7) prepared manuscripts for publication to report the new results regarding metallic grain boundaries.

Publications and Presentations

Zhu, R. E. Rudd, T. Frolov, 2017. "Predicting Phase Behavior of Interfaces with Evolutionary Algorithms." 2017 TMS Annual Meeting & Exhibition, February 26-March 2, 2017. San Diego, CA. LLNL-CONF-741774.

——— 2017. "Predicting Phase Behavior of Interfaces with Evolutionary Algorithms." PACRIM-12, May 21-26, 2017. Hawaii, HI. LLNL-ABS-708037.

Zhu, et al., 2017. "Predicting Phase Behavior of Interfaces with Evolutionary Algorithms." Computational Materials Science Group, April 19, 2017. LLNL. LLNL-ABS-741946.

——— 2017. "Predicting Phase Behavior of Interfaces with Evolutionary Algorithms." MS&T 2017, October 8-12, 2017. Pittsburgh, PA. LLNL-ABS-741945.