Matthew Mcnenly (16-ERD-003)

Executive Summary

By combining experiments with high-fidelity combustion simulations, we expect to be the first to predict new biofuel performance in an internal-combustion engine with less than a milliliter sample. This research will provide key scientific proof of the efficacy of small-volume fuel testing and serve as a cornerstone for future co-optimization of fuels and engines by leveraging the advanced computational solvers and high-fidelity chemistry mechanisms developed at Livermore.

Project Description

An 85-year gap separates fuel certification and modern automotive engines. The engine configuration used for fuel testing is very far removed from the operating conditions of modern production engines, which use high compression ratios, turbochargers, and direct fuel injection. These standard fuel measurements have even less connection to many proposed clean-engine concepts that use chemistry-controlled combustion such as those being researched under direction of the DOE Vehicle Technology Office. Even worse, these tests typically require at least one liter of fuel. The large test volumes make it infeasible to test many new bio-derived fuels and additives, which are often produced initially in very small batches. Our goal is to predict new biofuel performance with less than a milliliter sample, which has never been done. Leveraging the advanced computational solvers and high-fidelity chemistry mechanisms developed at LLNL, we will produce a predictive simulation of a small-volume fuel ignition tester (the micro-FIT) and develop a theoretical link with simulation between micro-FIT and engine performance in a high-efficiency, chemistry-controlled automotive engine. The success of the project will increase the number of biofuels currently tested for advanced engines by several orders of magnitude. If successful, such throughput will enable the simultaneous optimization of fuels and engines, which, by 2030, is projected to reduce vehicle petroleum consumption by 30% beyond current federal mandates.

We expect to become the first to predict new biofuel performance in an internal-combustion engine with less than a 1-mL sample. By combining experiments with high-fidelity combustion simulations, we will make blind performance predictions with very small volumes of biofuel blends that have never been tested in an internal combustion engine. With engine tests at the Combustion Research Facility at Sandia National Laboratories, we will validate these predictions. The micro-FIT device will eliminate the need to scale biofuel production to the liter scale for screening purposes, thereby increasing the test rate by several orders of magnitude. The advantage of our research approach is that it exploits a large set of time-dependent data to create a robust and quantitative fuel measurement, and is built on chemistry solvers that are one to three orders of magnitude faster than those used by other investigators. The large computational cost associated with simulating real transportation chemistry has limited others to studying steady, one-dimensional models of the micro-FIT device. We expect to create intellectual property for the design and optimization of advanced fuels for current and new combustion systems.

Mission Relevance

The project, which will provide key scientific proof of the efficacy of small-volume fuel testing and serve as a cornerstone for future co-optimization of fuels and engines, supports the Laboratory's energy and climate security mission focus area and the DOE's goal in science and energy to strengthen the connection between advances in fundamental science and technology innovation. Co-optimization will enable greater energy and climate security by reducing petroleum consumption. Our research methodology in fuel performance simulation and design is relevant to the Laboratory's core competency in high-performance computing, simulation, and data science, and should attract considerable collaboration and interest from the energy sector.

FY17 Accomplishments and Results

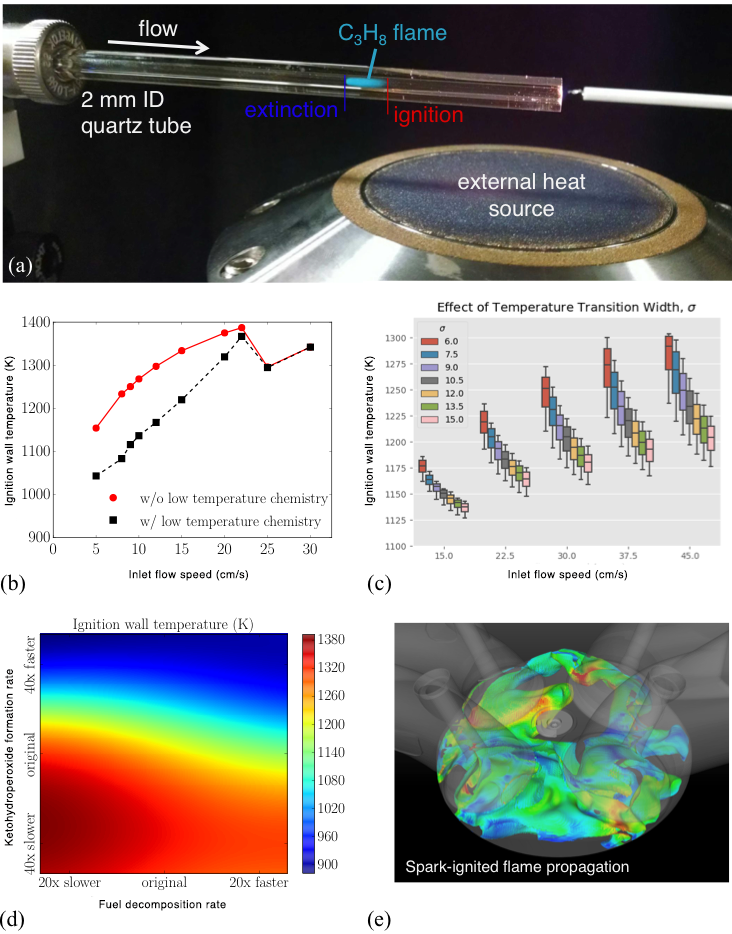

In FY17 we (1) accelerated the flame model for the micro-FIT device by increasing the method order and through parallelization to scale to thousands of computer central processing units, which was verified through comparisons with established computational fluid dynamics codes; (2) improved the physical accuracy of the proposed tester device with a multidimensional heat-transfer model, which was validated against experimental data; (3) implemented four different transport models to assess the impact on flame dynamics, and found that the constant Lewis number model, which has the lowest computer processor cost, leads to the same result (within the experimental accuracy) as more-complex transport models; and (4) demonstrated that a simplified chemistry model could be inferred from micro-FIT data, and can reproduce the auto-ignition time and flame speed (see figure).

Publications and Presentations

Druzgalski, C. L., S. Lapointe, and M. J. McNenly. 2017. "Quantifying Reaction Rates Sensitivity and Discoverability in a Millimeter-Scale Flow Reactor." 10th International Conference on Chemical Kinetics, Chicago, IL, 21–25 May 2017. LLNL-PRES-731701.

Lapointe, S., et al. 2017. "Simulations of a Micro-Liter Fuel Ignition Tester." 10th U.S. National Combustion Meeting, College Park, MD, 23–26 April 2017. LLNL-CONF-725138.