Manyalibo Matthews (15-ERD-037)

Project Description

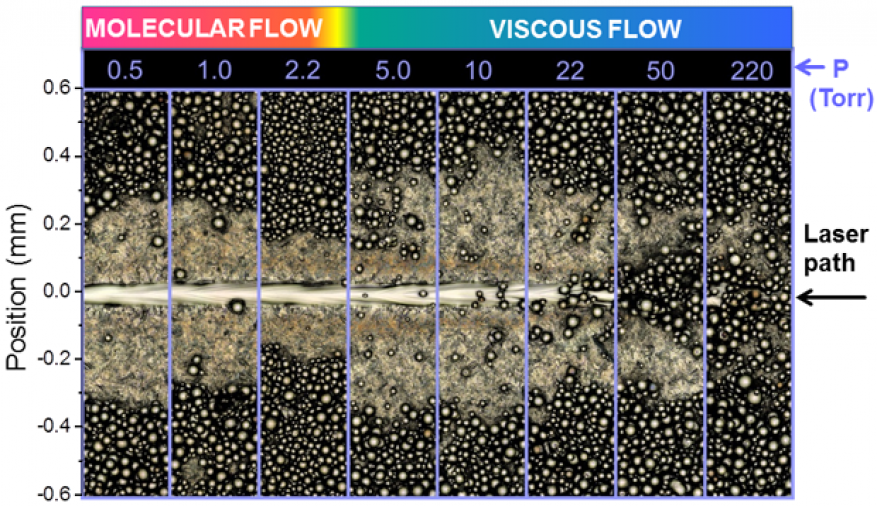

Recently, a growing number of laser-assisted advanced manufacturing methods have been introduced into industry, leading to reduction in cost, increase in processing speed, and access to material property modifications not possible with conventional processing. While seemingly simple, the process has many complex parameters: laser beam power and size, scan speed, powder material parameters, powder size and distribution over the ball-milled powder sizes, and powder thickness. The optimal processing parameters are determined mainly empirically for specific materials and powders only. To further improve selective laser melting, we must address several materials challenges. We are investigating the physics of laser-induced melting of metal powder layers. Our ultimate goal is to expand the scientific foundation associated with laser-assisted manufacturing processes through well-posed physics experiments and predictive modeling and simulation. Specifically, we plan to (1) develop a selective laser-melting optical test bench with in situ diagnostic capability; (2) execute experiments to capture the mesoscale thermal and morphological evolution of metal powders irradiated with laser light under varying conditions (as shown in figure); (3) simulate laser absorption, heat transport, phase transitions, and surface wetting in conjunction with the arbitrary Lagrangian–Eulerian three-dimensional hydrodynamics code; and (4) explore new methods to process metal powders, including feedback control and laser beam shaping.

Our primary experimental deliverable will be a functioning test bench that can be used to study laser-assisted manufacturing processes in situ under a wide variety of conditions. A mesoscale computational capability being developed in the arbitrary Lagrangian–Eulerian three-dimensional code will be validated using experimental data, allowing fine tuning of model parameters and guidance to full-scale material processing systems. We expect to address the detailed physics of laser absorption, dynamic heat transport, and material response of the selective laser melting process. Finally, we will aim to deliver an optical diagnostic solution useful in production-scale laser-processing platforms.

Mission Relevance

Our project addresses the Laboratory's strategic need of more agile and responsive material development and manufacturing techniques. The resulting validation of hydrodynamics code models will advance laser-assisted additive manufacturing as an integral part of the advanced materials and manufacturing core competency. Several LLNL capabilities, including lasers and optical materials, high-performance computing, and materials and advanced manufacturing, will be combined to probe the fundamental materials science and physics of laser-based surface processing of complex morphologies, leading to significant improvement to laser-assisted manufacturing capabilities.

FY16 Accomplishments and Results

In FY16 we (1) successfully installed a research and development platform and deposited a set of 16 density cubes that were correlated with in situ pyrometry data; (2) refined our in situ thermal sensing techniques to include high speed (10-kHz) dual-color thermography, which is currently being calibrated in our single-track system; (3) conducted high-speed light-scattering experiments (laser speckle); (4) began development of an optical coherence tomography system for in situ surface profiling on our research and development platform; and (5) performed a campaign of high-speed (up to one million frames/second) video experiments of the powder bed fusion process, revealing for the first time Bernoulli-driven particle entrainment of powder near the melt pool.

Publications and Presentations

- Chapman, C. A. R., "Engineering on-chip nanoporous gold material libraries via precision photothermal treatment." Nanoscale 8, 785 (2016). LLNL-JRNL-674038. http://dx.doi.org/10.1039/c5nr04580k

- Chapman, C. A. R.,"Utilizing dynamic laser speckle to probe nanoscale morphology evolution in nanoporous gold thin films." Optic. Express 24, 5323 (2016). LLNL-JRNL-680722. http://dx.doi.org/10.1364/OE.24.005323

- Matthews, M., "Denudation of metal powder layers in laser powder bed fusion processes." Acta Mater. 114, 33 (2016). LLNL-JRNL-680585. http://dx.doi.org/10.1016/j.actamat.2016.05.017