Program Value

By almost any measuring stick, the LDRD program contributes far more in publications, intellectual property, collaborations, and recruitment of postdoctoral researchers—dollar for dollar—than any other program at the Laboratory.

- Collaborative Explorations

- Intellectual Property

- Scientific Publications

- Early Career

- Professional Fellows

- Long-term Impact

Collaborative Explorations

External collaborations are essential to the innovative research that takes place at LLNL, including LDRD-funded projects. By collaborating with other national laboratories, academia, and industry, our investigators can engage with experts from other institutions and access world-class experimental facilities.

The following table provides our most recent data regarding formal collaborations, which we define as LDRD-funded projects where an external collaborator received LDRD funds from LLNL. In addition, our investigators frequently participate in informal collaborations with researchers at other institutions, which often involves joint scientific publications. Both types of collaborations are a key indicator of the broad intellectual engagement that is a hallmark of LLNL’s research environment.

56 institutions were involved in formal collaborations with LLNL as part of LDRD-funded

research teams in FY20

| Collaborations | FY16 | FY17 | FY18 | FY19 | FY20 |

|---|---|---|---|---|---|

| LDRD-funded projects with one or more formal collaborations | 45 | 62 | 74 | 74 | 78 |

| Percentage of all projects at LLNL | 25% | 29% | 31% | 30% | 32% |

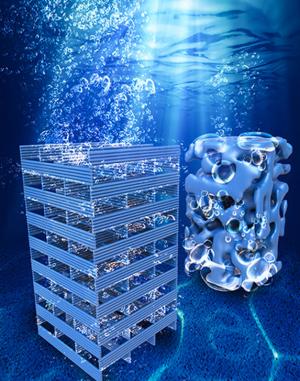

Innovative design of 3D-printed electrodes increases catalytic activity

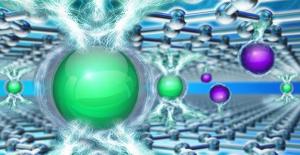

Rechargeable metal–air batteries show tremendous promise for safe, low-cost, high-capacity energy storage, offering an alternative to lithium–ion batteries that are reaching their energy density limit. However, the energy-delivery capacity of metal–air batteries is currently constrained by sluggish kinetics that limit the catalytic activity of these compact power sources.

An LDRD-funded research team at LLNL partnered with investigators from two University of California campuses—Santa Cruz and Merced—to improve the catalytic potential of metal–air batteries. They developed a new electrode design that rapidly eliminates the gas bubbles that can get trapped in the material and reduce current density.

“The gas bubbles that are created during electrolysis often mingle together and get trapped,” explained the project’s lead investigator, LLNL materials scientist Cheng Zhu. “Our new electrode design pulls out the bubbles as quickly as possible so they don’t reduce the electrode’s catalytic activity.”

While developing the electrode’s architecture, the team used simulations to explore how the gas bubbles form, how they escape, and the rate at which they escape. The structural modeling enabled the team to explore the physics going on inside the electrodes and identify ways to more effectively manage bubble migration through a hierarchical porous structure.

The team designed, fabricated, tested, and optimized the structure of the three-dimensional (3D) printed electrode, demonstrating that it can eliminate the physical barrier between catalyst and reactant, and significantly improve the electrode’s current density.

“While other investigators have studied the material side of electrolysis, this team showed that the actual architecture of the components matter just as much as the materials, especially at high production rates,” said Brandon Wood, who leads LLNL’s research initiatives in hydrogen energy materials.

By improving the catalytic activity of advanced batteries, this research provides a promising pathway to further enhance energy storage capabilities, as well as our nation’s ability to deliver clean, hydrogen-based energy.

LDRD Project Title: Rational Design of Bifunctional Electrocatalysts for Rechargeable Metal–Air Batteries

Principal Investigator: Cheng Zhu

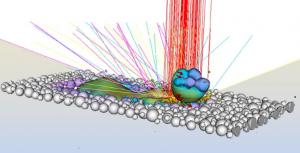

Simulations identify novel way to mitigate defects and customize laser-driven metal fabrication

In collaboration with investigators at the Air Force Research Laboratory, LLNL scientists tackled a challenge associated with laser-based metal fabrication, tapping into multi-physics simulation capabilities to identify a novel solution. Experiments alone could not fully explain the dynamics behind a process that causes defects when using a laser-based additive manufacturing (AM) process to form 3D metal parts.

When fabricating 3D parts using laser powder-bed fusion, where a laser beam melts metal powder layer-by-layer to form parts, clusters of powder particles ejected from the laser’s path can land back on the parts and potentially lead to defects. During this LDRD-funded research project, investigators explored the mechanisms behind how this “spatter” forms, and how to modify the fabrication process to prevent large amounts of spatter.

Since experiments lack the required spatial and temporal resolution to follow the fast dynamics (approximately 1 microsecond) behind the laser-spatter interactions, researchers used computer models to create a digital twin of the process. Using the predictive model, along with high-speed x-ray and optical imaging, they established a stability criterion, creating a power map that controls the laser’s power output along its scan vector, thereby maintaining a stable melt pool and avoiding large amounts of spatter.

According to Ibo Matthews, who led the LDRD project and has analyzed melt-pool dynamics for several years, modulating the laser power makes it possible to avoid disturbing the powder bed. “The ability to control the energy input using validated models opens up pathways to defect mitigation, as well as material enhancement through tailored microstructure engineering,” said Matthews.

The team anticipates that the model-driven scanning strategy, which includes precise temporal and spatial control of the laser-energy source, will improve overall part reliability by enabling more uniform properties of 3D-printed parts. In addition, the new approach may also enable opportunities to use this additive manufacturing technique with new types of materials that traditionally fail during a part build.

LDRD Project Title: A New Science-Based Paradigm Enabling Microstructure-Tailored Additive Manufacturing of Metals

Principal Investigator: Ibo Matthews

Intellectual Property

Year after year, projects sponsored by LDRD achieve a disproportionately large percentage of the patents and copyrights issued for LLNL research. As illustrated in the following tables, LDRD-funded work has been key in developing more than half of the Laboratory's patents, one-fifth of the Laboratory's copyrights (chiefly computer code), and about half of the Laboratory's records of invention.

| Patents | FY16 | FY17 | FY18 | FY19 | FY20 |

|---|---|---|---|---|---|

| All LLNL patents | 97 | 88 | 79 | 143 | 200 |

| LDRD patents | 54 | 55 | 41 | 95 | 131 |

| LDRD patents as a percentage of total | 56% | 63% | 52% | 66% | 66% |

| Copyrights | FY16 | FY17 | FY18 | FY19 | FY20 |

|---|---|---|---|---|---|

| All LLNL copyrights | 72 | 105 | 105 | 118 | 138 |

| LDRD copyrights | 19 | 19 | 23 | 24 | 31 |

| LDRD copyrights as a percentage of total | 26% | 18% | 22% | 20% | 22% |

| Records of Invention | FY16 | FY17 | FY18 | FY19 | FY20 |

|---|---|---|---|---|---|

| All LLNL records | 91 | 110 | 105 | 129 | 126 |

| LDRD records | 43 | 53 | 47 | 65 | 56 |

| LDRD records as a percentage of total | 47% | 48% | 45% | 50% | 44% |

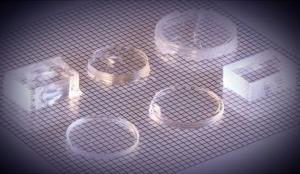

Volumetric additive manufacturing enables fabrication of 3D-printed objects in a single step

A breakthrough technology developed by LLNL investigators in collaboration with researchers at the University of California, Berkeley, creates an entire three-dimensional part at once, rather than in a series of steps. The idea for this innovative approach to additive manufacturing started several years ago, and through a series of LDRD-funded projects, it has now resulted in a patented technology with a broad array of applications—including national security, aerospace, optics, medicine, dentistry, and energy delivery.

In the patented process known as computed axial lithography (CAL), a projector beams a series of computer-generated images into a container of photosensitive, syrup-like resin while the container rotates. After a few minutes, a fully-formed 3D object solidifies, suspended in the resin, and the remaining liquid can be drained. Uniquely shaped polymer parts with complex geometries can be made much more quickly with CAL than with layer-by-layer fabrication methods.

According to Maxim Shusteff, an LLNL engineer who led both LDRD-funded projects, the goal of this research was to develop a technique that could overcome the drawbacks of layer-by-layer 3D printing, where each layer takes a minute to print. With parts that can include hundreds of layers, it can take a long time to print each part. In addition, the resulting parts often have undesirable properties, such as rough edges or disconnected islands of material.

In contrast, this novel volumetric AM approach enables an object to be supported by the buoyancy of the surrounding liquid as it is fabricated. “We can print extremely delicate microstructures in soft materials,” said Shusteff. “CAL eliminates many of the fabrication constraints that engineers and the bioprinting community have been facing for a long time."

As industry collaborators explore new applications for this innovative technology, the LDRD-funded research team at LLNL is exploring new types of photocurable materials that can be used with CAL to fabricate a broader range of parts.

“Available polymers present limitations such as brittleness and poor aging performance that can occur months or years after curing is completed,” Shusteff explained. “Our current research focuses on developing photocurable materials for AM with architectures that provide superior mechanical properties, along with dependable lifetime performance.”

Current industry partners include a bioprinting company and an advanced materials company. Each partner is exploiting different features of the volumetric AM approach to increase the competitive technological edge of their products.

LDRD Project Titles: Advanced Photopolymer Materials Engineering for Multiscale Additive Fabrication; and Three-Dimensional Fabrication by Tomographic Holographic Lithography

Principal Investigator: Maxim Shusteff

LDRD Projects 19-ERD-012; and 17-ERD-116

Tailored glass optics offer design flexibility for laser applications

An innovative optical technology developed through a series of LDRD-funded projects, initially demonstrated for laser applications, may also help address industry needs related to improving lightweight optical systems.

Research started in 2016, when the LDRD team began exploring ways to additively manufacture optics with the physical shapes and refractive-index profiles of interest for reducing the size, weight, and power of optical systems. Because additive manufacturing offers the ability to control both structure and composition, the research team was able to modify what had historically been a highly constrained design process, instead providing the design flexibility needed to produce gradient-refractive-index optics with the desired sizes and profiles.

LLNL investigators focused on the material composition needed to create tailored, lightweight optics, along with innovative approaches to fabricate optical components with unique structures. They used an additive manufacturing technique known as direct-ink writing (DIW), enabling them to actively control the ratio of glass-forming feedstock materials as they were blended together. For example, they used specially formulated silica-containing pastes or resins, and by changing the proportions of the different types of inks while printing, they were able to alter the refractive index. After the optical preform is built, it is densified to glass, and can be finished using conventional optical polishing.

“The change in material composition leads to a change in refractive index once we convert it to glass,” explained LLNL chemical engineer Rebecca Dylla-Spears, who leads LLNL’s multidisciplinary research team that includes experts in materials science, optical engineering, and laser technology.

The technique is expected to enable scientists to produce lightweight, environmentally stable, flat glass components (with no surface curvature). The gradient-refractive-index optics alter how light travels through the medium, so that the lens can have a flat surface, yet still perform the same optical function as an equivalent conventional lens.

LLNL scientists are exploring potential industry applications of this technique, including the ability to produce lightweight, tailored components for optical systems.

LDRD Project Title: Glass Inks for Three-Dimensional Printed Fiber Preforms and Telescope Optics

Principal Investigator: Rebecca Dylla-Spears

Scientific Publications

Laboratory scientists and engineers publish more than a thousand papers each year in a wide range of peer-reviewed journals, of which LDRD-funded work accounts for a large portion. The numerous publications made possible through LDRD-sponsored research help the Laboratory maintain a strong presence in the broader scientific community, extending the impact of LDRD research beyond the DOE mission space into the wider scientific arena. In addition, the impact of these publications documenting LDRD project results extends long after articles appear in the journals, increasing the value of LDRD investments in these projects.

| Journal Articles | FY16 | FY17 | FY18 | FY19 | FY20 |

|---|---|---|---|---|---|

| All LLNL articles | 1,041 | 1,126 | 1,178 | 1,281 | 1,149 |

| LDRD articles | 265 | 274 | 456 | 553 | 428 |

| LDRD articles as a percentage of total | 25% | 24% | 39% | 43% | 37% |

LDRD Research Featured in Peer-reviewed Journals

LDRD-funded research was featured in the Journal of Applied Physics. The article was one of many scientific publications produced as part of an LDRD exploratory research project, where investigators developed a new, computationally efficient modeling framework to predict how superconducting circuits respond in the quantum regime.

As highlighted in the article, investigators used first-principles modeling to assess fundamental aspects of the atomic structure of amorphous and crystalline tunnel junctions, which are critical components of superconducting circuits used in quantum computers. The project contributes enabling capabilities to support long-term needs in quantum-coherent superconducting device design for sensors, simulation, and information processing.

LDRD Project Title: Predictive Modeling of Correlated Noise in Superconducting Circuits

Principal Investigator: Vince Lordi

LDRD-funded research was also featured on the cover of the Journal of Chemical Information and Modeling, highlighting efforts to leverage the capabilities of machine learning to accelerate materials discovery and optimization. As highlighted in the article, the team developed a machine learning tool that that can extract and structure information from the text and figures in scientific publications regarding nanomaterials.

The research team tapped into their expertise in materials science and data analytics to develop an automated information-extraction pipeline that uses natural-language processing image analysis and visualization techniques to identify and analyze microscopy images of nanomaterials and determine their morphologies and size distributions. They also created a knowledge base regarding nanomaterials synthesis that can be mined to help inform further nanomaterials development.

Since concluding their LDRD-funded project, the research team has applied their machine learning tools to extract information from the SARS-CoV-2 and COVID-19 literature, which is being analyzed for its utility in accelerating COVID-19 research.

LDRD Project Title: Materials Informatics for Synthesis, Optimization, and Scale-Up of Advanced Materials

Principal Investigator: T. Yong Han

LDRD-funded research regarding modeling the human central nervous system was featured on the cover of the Lab on a Chip journal and an article describing how the team developed a thin-film, three-dimensional, flexible, microelectrode array (3DMEA) that non-invasively monitors a 3D culture of neurons and records neuronal function.

The platform is an important step in facilitating non-invasive electrophysiological characterization of 3D networks of electroactive cells in vitro. This capability can enhance our understanding of how the human brain responds to infection, disease, and chemical exposure, underpinning the development of therapies and therapeutics.

LDRD Project Title: An Investigational Platform of the Human Brain for Understanding Complex Neural Function

Principal Investigator: Nick Fischer

Early Career Opportunities: Students and Postdoctoral Fellows

By funding exciting, potentially high-payoff projects at the frontiers of science, the LDRD program attracts top talent in new and emerging fields of science and technology. As shown in the following tables, LDRD investments contribute to the health and robustness of LLNL's student and postdoctoral researcher programs.

| Students | FY16 | FY17 | FY18 | FY19 | FY20 |

|---|---|---|---|---|---|

| Students supported by LDRD | 102 | 127 | 138 | 160 | 101 |

| Percentage of all students | 19% | 22% | 22% | 23% | 18% |

| Postdoctoral Researchers | FY16 | FY17 | FY18 | FY19 | FY20 |

|---|---|---|---|---|---|

| Postdoctoral researchers supported by LDRD ≥10% of their time | 107 | >137 | >167 | 170 | 208 |

| Percentage of all postdoctoral researchers | 39% | 44% | 54% | 57% | 63% |

| LDRD postdoctoral researchers converted to full staff | 25 | 31 | 52 | 46 | 60 |

| Percentage of all conversions | 69% | 53% | 71% | 68% | 77% |

Doctoral fellow improves codes used to simulate interactions between particles moving at high velocities

Doctoral fellow Marco Echeverria is part of an LDRD-funded research team exploring interaction between ejecta—particles ejected from a material's surface following shock-driven processes that cause the micron-sized particles to travel at high velocities. For example, they are studying metal ejecta generated from copper and tin material samples during high-power laser experiments, comparing how the mass, velocity, and material phase influences particle interaction.

According to LLNL physicist Alison Saunders, principal investigator of the LDRD project, gaining a better understanding of ejecta interactions has a broad range of applications, such as spacecraft shielding, cold-spray welding, additive manufacturing, and understanding material strength at small scales.

Echeverria’s most recent role on the project focused on improving hydrodynamics codes used to model phenomena that occur during high-energy experiments. “It’s challenging to simulate the material’s microstructure at a large scale,” he explained. “By feeding better experimental data into the hydrocodes, combined with data from molecular dynamics, scientists can conduct more realistic simulations at experimental scales.”

Echeverria is a GEM fellow, sponsored by LLNL. The National GEM Consortium enables qualified students from underrepresented communities to pursue graduate education in science and engineering. Echeverria is earning a doctoral degree in materials science and engineering from the University of Connecticut and had originally planned a career in academia. After experiencing the research environment at LLNL, his plans shifted.

“I really like the close connection between experimental work and modeling that’s possible in a national lab research environment,” Echeverria said. “It’s exciting to be able to reverse-engineer simulation codes based on experimental results.”

“We are thrilled that Marco chose to be part of this research team,” said Will Evans, who leads LLNL’s Physics Division. “Sponsoring GEM fellows is an important part of our efforts to attract a diverse group of talented young physicists to the Laboratory and expand collaborations in the broader physics community.”

LDRD Project Title: Metal Ejecta: Transport, Interaction, and Recollection

Principal Investigator: Alison Saunders

Summer students explore ways to optimize the performance of desalination technology

A group of summer students were able to dive into research aimed at increasing access to fresh water, as part of an LDRD-funded project that explored methods to improve the performance of capacitive deionization (CDI), a desalination technology. They participated in experiments exploring how to overcome barriers that can limit the performance of CDI technology, which uses cyclic charging and discharging of electrodes to selectively remove ions and reduce the salinity of water.

One undergraduate summer student, Helen Kuo, also was the lead author of a journal article published in Environmental Research: Water Research & Technology. According to Kuo, “We detailed new methods for separating contact resistance vs. electrode resistance, and we provided an explanation of poorly understood impedance features. These measurements will help us design more efficient CDI cells.”

After working with her mentor to design the experiments, Kuo built a series of CDI cells with different current-collector materials, including graphite and titanium, and used two- and four‑electrode measurements to decouple contact resistance from electrode resistance. In doing so, the team addressed a long-standing mystery in interpreting impedance measurements in porous electrochemical systems, presented a novel way to characterize current-collector degradation, and identified the top limitations of their own cell design.

LLNL scientist and co-author Steven Hawks said the talent and productivity of the undergraduate students were key to the project’s success. The work has significant implications for scale-up of CDI systems and future improvements of cell design.

LDRD Project Title: Selective Removal of Ions from Aqueous Solutions

Principal Investigator: Patrick Campbell

Professional Fellows

One relevant indicator of advancement and leadership in a scientific field is the election of individuals as fellows of professional societies. This indicator reflects success for both the individual researcher and the Laboratory as a whole.

American Physical Society (APS) fellowships are awarded based on scientific merit and impact over an extended period of time, and the evaluation process relies on nomination and recommendation by peers. As such, data regarding the history of APS fellowships awarded to LLNL physicists provide an important indicator regarding the key role that the LDRD Program plays in developing the technical, scientific, and leadership skills of early career staff. As presented in the following table, for fiscal year 2020, 100% of the new APS Fellows from LLNL have early career LDRD experience.

Because the quantity of awards each year is a small number, we also present multi-year statistics. For example, over the last 20 years, more than 90% of the APS Fellows at LLNL had early career LDRD experience.

| Single-Year Statistics | Multi-Year Statistics | |||||

|---|---|---|---|---|---|---|

| History of APS Fellows at LLNL | FY18 | FY19 | FY20 | FY11-15 (5 yrs) |

FY16-20 (5 yrs) |

FY00-20 (21 yrs) |

| Total APS awards | 4 | 6 | 4 | 25 | 21 | 94 |

| Awards with LDRD roots | 4 | 5 | 4 | 24 | 20 | 87 |

| % with LDRD roots | 100% | 83% | 100% | 96% | 95% | 93% |

| Average years from first LDRD experience | 18.0 | 15.6 | 20.8 | 13.6 | 18.2 | 12.7 |

Tracing impact to LDRD roots

Throughout this section, we mention “LDRD roots.” There is often a lot of discussion with principal investigators about what it means for an accomplishment to have LDRD roots. A simple case would be if an idea for an invention arises during an LDRD project and work on the invention is completed during the period of LDRD investment. But R&D often does not advance on such a short timescale. In general, an accomplishment (invention, paper, capability, etc.) is determined to have LDRD roots if at least one LDRD project needed to occur for the accomplishment to take place. In other words, if one can identify an LDRD project that was critical to the accomplishment, then it is considered to have LDRD roots.

2020 APS Fellows at LLNL

Four LLNL scientists were selected as 2020 fellows of the American Physical Society. These new fellows represent a range of physics expertise, including laser-plasma physics, magnetic-fusion plasmas, condensed-matter physics, and theoretical and computational understanding of plasma interactions.

Richard Berger

“I am grateful to my colleagues who nominated me, and I am very pleased to receive this recognition.”

Richard Berger, a theoretical plasma physicist at LLNL, was recognized for his pioneering vision regarding the crucial theoretical and computational understanding of plasma interactions with intense light and other high-energy-density plasmas. He joined LLNL in 1991, and his LDRD-funded work reflects his research focus on fluid and kinetic simulation of laser-plasma interactions, as well as multi-fluid hydrodynamics and kinetic instabilities driven by interpenetrating plasma flows.

Laurent Divol

“I am honored to have been selected. I feel this fellowship is a recognition of my contributions to many ICF projects—an opportunity that is truly unique to national labs."

LLNL physicist Laurent Divol was selected as an APS fellow for fundamental contributions to laser-plasma physics in hohlraums and other high-energy-density experiments, and for leadership in the design of high-yield deuterium-tritium experiments. Divol joined LLNL in 2001 and works on many projects related to inertial confinement fusion (ICF), with a focus on research involving lasers and plasmas. His LDRD roots include a project in which he developed a novel scheme for guiding laser beams in plasmas.

Max Fenstermacher

“I'm very grateful to have worked with great team members who were key to the new physics understanding obtained through our research, which was cited in this award.”

Plasma physicist Max Fenstermacher was recognized for his experiments and modeling related to understanding tokamak divertor detachment, as well as the characterization and control of edge-localized modes (ELMs) with resonant magnetic perturbations in magnetic-fusion plasmas. He started his career at LLNL in 1983, and since 1994 he has served as a member of the LLNL experimental team at the DIII-D National Fusion Facility in San Diego. His LDRD-funded research includes studies of heat loads in tokamaks, including measuring and analyzing ELM behavior with diagnostics on the two largest U.S. tokamaks.

Art Nelson

“I am truly honored to be selected as an APS fellow, and I appreciate my many colleagues in the Peak Brightness Collaboration for supporting my nomination.”

Art Nelson, an expert in condensed-matter physics, was recognized for his outstanding contributions to the development of soft x-ray and free-electron laser analytical platforms and pump-probe techniques applied to understanding ultrafast surface phenomena and extreme states of matter. He has worked at LLNL for 22 years, and his LDRD-funded work aligns with his research focus on studying surface catalytic reactions and designing novel materials for energy applications.

Long-term Impact

The LDRD program is an investment in our nation’s future, ensuring mission support that is often realized many years after an LDRD-funded project concludes. Recognizing this long-term impact of the LDRD program, we believe it is important to highlight indicators that span multiple years, demonstrating the true impact of LDRD as a national asset.

We collaborated with our colleagues from LDRD programs at other NNSA institutions to identify ways that we could best represent the long-term impact of LDRD investments. For the first time, as each institution issues its LDRD program report for fiscal year 2020, we are presenting a common set of long-term performance indicators, which include the content provided below.

Distinguished Member of the Technical Staff

One relevant indicator of career advancement in a science and technology field is the recognition of individuals as distinguished members of the technical staff at the institution. Individuals who receive this recognition are identified as being in the top 1% or 2% of the institution’s scientific and technical staff, similar to a lifetime achievement award, or in this case, for their contribution to the Laboratory’s mission.

At LLNL, appointment as a Distinguished Member of the Technical Staff (DMTS) is reserved for Laboratory scientists and engineers who have demonstrated a sustained history of high-level achievements in programs of importance to the Laboratory, become a recognized authority in the field, or made a fundamental and important discovery that has sustained, widespread impact.

As presented in the following table, a vast majority of these distinguished staff at LLNL had early career experience with LDRD projects, which helped them develop their scientific, technical, and leadership skills.

| Single-Year Statistics | Multi-Year Statistics | |||||

|---|---|---|---|---|---|---|

| History of DMTS Awards at LLNL | FY18 | FY19 | FY20 | FY11-15 (5 yrs) |

FY16-20 (5 yrs) |

FY00-20 (21 yrs) |

| Total DMTS awards | 4 | 6 | None | 34 | 14 | 48 |

| DMTS with LDRD roots | 4 | 6 | N/A | 27 | 14 | 41 |

| % with LDRD roots | 100% | 100% | N/A | 79% | 100% | 85% |

| Average years from first LDRD experience | 23.8 | 17.5 | N/A | 18.1 | 21.1 | 19.1 |

R&D 100 Awards

Another indicator of advancement and leadership in a scientific field is the R&D 100 Award program, which honors the top innovations of the past year. R&D 100 Awards can occur a long time after the initial ideas are developed, often during LDRD projects. Typically, it takes 5 to 10 years (or longer) from concept development to receiving an award, including the time needed to move through patenting an invention and demonstrating its commercial applications.

As presented in the following table, over the last 20 years, approximately half of LLNL’s R&D 100 Awards had roots in the LDRD Program.

| Single-Year Statistics | Multi-Year Statistics | |||||

|---|---|---|---|---|---|---|

| History of R&D 100 Awards at LLNL | FY18 | FY19 | FY20 | FY11-15 (5 yrs) |

FY16-20 (5 yrs) |

FY00-20 (21 yrs) |

| Total R&D 100 Awards | 0 | 4 | 1 | 20 | 15 | 89 |

| Awards with LDRD roots | N/A | 2 | 0 | 11 | 4 | 45 |

| % with LDRD roots | N/A | 50% | 0% | 55% | 27% | 51% |

| Average years from first LDRD investment | N/A | 12.0 | N/A | 6.5 | 8.8 | 6.2 |