Bernard Kozioziemski (15-ERD-063)

Project Description

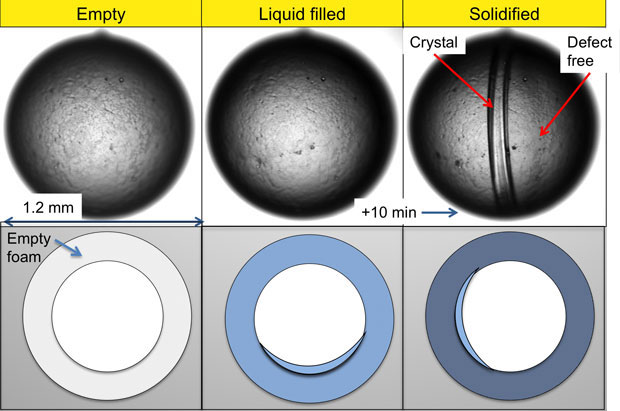

Very low-density foams have been proposed for use in Inertial Confinement Fusion targets on advanced fusion-class lasers to stabilize the configuration of the deuterium–tritium fuel capsule. We plan to develop the underlying science needed to understand the solidification process of hydrogen (deuterium–tritium) fuel layers in foams to optimize Inertial Confinement Fusion target designs by minimizing the foam layer surface roughness for a given central vapor pressure and foam density. The foam material must have a high uniformity for ideal implosion for fusion. Confined geometries, such as nanometer-scale pores in vycor glass, have been shown to suppress solidification. A previous study examined, in part, the solidification of hydrogen in open-cell foams, but the results did not match the simple model for thermodynamic suppression of solidification. It is likely that solidification in an open-cell foam geometry proceeds very differently than in the closed-cell geometry. Therefore, we intend to study the basic processes that drive solidification in foams, including the roles that the foam geometry, density, pore size distribution, surface area, and material play in the solidification process.

We expect to identify the foam characteristics necessary to control the solidification of hydrogen, which inhibits the smooth fuel layers required for implosion in a laser fusion capsule. These characteristics would be used to define the range of foam densities and materials for which uniform deuterium–tritium fuel layers would be produced (see figure). Specifically, we intend to measure hydrogen-fill fraction, vapor pressure in foams and controlled pore glasses, and temperature for solidification. We will design, build, and test a cryogenic hydrogen cell for study of solid hydrogen in foam, as well as perform detailed characterization of these foams by high-energy ion scattering, gas sorption, electron microscopy, and calorimetric procedures. We plan to attract a postdoctoral candidate in material sciences to support this research effort.

Mission Relevance

Suppression or enhancement of nucleation by the foam would serve to make smooth, uniformly thick deuterium–tritium fuel layers for inertial-confinement applications, including doping of the foam for uses of ignition, in support of the Laboratory's strategic focus area of inertial fusion science and technology with high-gain target design. In addition, our research aligns with the core competency in high-energy-density science.

FY16 Accomplishments and Results

In FY16 we (1) used atomic layer deposition of aluminum oxide on zinc substrates to demonstrate that surface shape and roughness are responsible for nucleation of the hydrogen solid on zinc, not an interaction with zinc itself; (2) determined that hydrogen will form a liquid layer on surfaces well below the melting temperature as grown from the vapor phase; (3) designed a new sample cell to measure the surface energy of the solid–liquid interface of the hydrogen; and (4) developed molecular dynamics simulations that can compare freezing point suppression in confined geometries with experimental results.

Publications and Presentations

- Kozioziemski, B., “Supercooling of hydrogen on template materials to deterministically seed ignition-quality solid fuel layers.” Fusion Sci. Technol. 70, 184 (2016). LLNL-JRNL-705308. http://dx.doi.org/10.13182/FST15-212