Marie-Anne Descalle (13-ERD-048)

Abstract

Our research focused on demonstrating the ability to detect and measure hard x-ray emissions using multilayer x-ray reflective optics above 400 keV. The purpose is to enable the development of inexpensive and high-accuracy mirror substrates and to investigate applications of hard x-ray mirrors of interest to the nuclear security community. Experiments conducted at the European Synchrotron Radiation Facility in Grenoble, France, demonstrated hard x-ray mirror reflectivity up to 650 keV for the first time. Three materials were evaluated as potential substrates: polycarbonates, thin Schott glass, and a new type of flexible glass called Willow Glass. Chemical smoothing and thermal heating of the surface of polycarbonate samples, which are inexpensive but have poor intrinsic surface characteristics, did not yield acceptable surface roughness. (Hard x-ray optics substrates must have surface roughness under 3 to 4 Å rms.) D263 Schott glass was used for the focusing optics of the National Aeronautics and Space Administration's NuSTAR (Nuclear Spectroscopic Telescope Array) telescope. The required specialized hardware and process were costly and motivated experiments with a modified non-contact slumping technique. The surface roughness of the glass was preserved and the process yielded cylindrical shells with good net shape, pointing to the potential advantage of this technique. Finally, the measured surface roughness was between 2 and 2.5 Å rms for Willow Glass sheets with thicknesses of 200 and 130 µm. Additional results of flexibility tests and multilayer deposition campaigns indicated this flexible glass is a promising substrate for hard x-ray optics.

The detection of uranium and plutonium characteristics x-ray lines and gamma emission lines in a high background environment was identified as an area for which x-ray mirrors could have an impact and where focusing optics could help improve the signal-to-noise ratio by focusing the signal onto a smaller detector. We therefore designed the first of twelve segments of a Wolter I focusing optics for the 90- to 140-keV energy range based on aperiodic multilayer coating.

Finally, we conducted the first demonstration that reflective multilayer mirrors could be used as diagnostics for high-energy-density experiments with an order of magnitude improvement in the signal-to-noise ratio for the multilayer optic compared to a transmission crystal spectrometer.

Background and Research Objectives

The nation continues to search for technologies and techniques to address longstanding problems and anticipate emerging challenges in nonproliferation, including the ability to search for special nuclear materials and weapons, perform attribution in the event of an attack or interdiction of a device, and strengthen the safeguards required for treaty obligations. The ability to detect hard x-ray or soft gamma-ray emissions (photons ranging to several hundred kiloelectronvolts) from special nuclear materials plays an important role in a number of these national security applications. The use of hard x-ray optics offers one path to dramatically improve performance by increasing photons collected from weak sources or by filtering out a background signal that obscures an important spectral signature.

The last two decades have seen the fast development of hard x-ray focusing optics driven by the astrophysics community needs and the development of multilayer coatings for new applications related to synchrotron research, medical imaging, and nonproliferation. The first multilayer-coated hard x-ray focusing optics for energies above 10 keV was launched in 2012 on board the National Aeronautics and Space Administration's NuSTAR satellite.1,2 Whereas the NuSTAR telescopes were designed for energies below 80 keV, multilayer-coated hard x-ray mirror specular reflectance was recently demonstrated at unprecedented energies up to 384 keV, opening new possibilities for applications.3,4

Our goal in this research was to demonstrate the ability to detect and measure hard x-ray emissions using multilayer x-ray reflective optics in a range of energy up to 650 keV—almost a factor of two increase in operational range. This increased range could enable new applications such as applications related to the detection of a 511-keV positron annihilation line. Other possible applications include the development of inexpensive and high-accuracy mirror substrates and applications of interest to the nuclear security community.

Scientific Approach and Accomplishments

First Demonstration of Hard X-Ray Mirror Reflectance above 400 keV

Experiments conducted at the European Synchrotron Radiation Facility demonstrated that at 508 keV (close to the 511-keV positron annihilation line) and at 644 keV, x-rays are reflected by multilayer mirrors at the predicted Bragg angle.5

Hard X-Ray Mirror Substrates

We conducted research focused on making inexpensive x-ray optics substrates (plastics or glass) with predictable, reliable performance. The production of smooth slumped glass substrates is expensive and current techniques to obtain segmented cylindrical shells rely on direct slumping of thin glass sheets on ultrasmooth diamond-turned cylindrical quartz mandrels to maintain smooth surface characteristics. For example, NuSTAR optics were optimized for the 10- to 79-keV range and made of over 2,376 mirror segments organized in 133 concentric layers—each segment is made of 210-µm-thick D263 Schott glass with surface roughness less than 3 to 4 Å. Over 40 mandrels of increasing radii were required for the slumping process, which represented a significant part of the cost of a nested focusing optics. We considered three types of substrates for our energy range of interest: polycarbonates, Schott glass, and Willow Glass, which is a new type of flexible glass developed by Dow Corning. A substrate figure of order 2 to 3 Å at most is required. Atomic force microscopy was conducted on each sample to evaluate surface roughness, post-treatment.

Polycarbonate

A substrate made of lightweight thin polyethylene terephthalate plastic foil for x-ray telescopes was first investigated about a decade ago.6–8 However, the plastic used in these experiments had unique surface properties not found in common polycarbonates. Polycarbonates are a type of plastic readily available in sheets that can be easily bent but have poor surface finish.9 In our experiments, chemical surface smoothing of 375-mm thick polycarbonate sheets with methylene chloride under various conditions of exposure time and temperature and proximal thermal heating as a function of distance, time, and temperature did not yield the surface roughness required for hard x-ray mirror substrates.

Glass Slumping

Combining non-contact mirror slumping technology and electrostatic imprinting, we investigated slumping of 210-µm D263 Schott glass into a concave graphite mold.10–12 Graphite is a factor of 20x cheaper than quartz mandrel, can be turned into a smooth surface, and has a coefficient of thermal expansion well matched to that of glass. The glass was heated in a dedicated furnace to temperatures between 600 and 800°C. Argon gas was injected through the mold to provide a thin gas-bearing film between the glass and the mold to avoid any imprinting of the mold surface imperfections through the glass. In addition, electrostatic force assist was applied to compensate for a "bubble effect" at the surface of the glass due to the gas–film pressure differential. Atomic force microscopy confirmed that the glass surface roughness was preserved and remained at <3 Å. Furthermore, the net shape of the slumped cylindrical shell was measured at the Nevis Laboratories at Columbia University, Irvington, New York, and was of order 25 ± 9 arcsec, a result well within the desired range.

Flexible Glass Substrate

During the last year of the project, Willow Glass became available. Flexible substrates made of such flexible glass could open the door to significantly cheaper focusing optics, assuming the substrate could be coated flat and bent into the desired shape. This process would bypass the glass slumping phase and simplify the geometry involved in multilayer deposition.

We studied several parameters (surface roughness, minimum bend radius, multilayer adhesion, and reflectivity) to determine the potential of using Willow Glass as substrate for hard x-ray multilayer coatings. The surface roughness measured with atomic force microscopy was about 2 to 2.5 Å rms, suitable for a high-energy x-ray optics substrates. We bent 200- and 130-µm Willow Glass sheets around cylinders with radii ranging from 10 to 3.8 cm. The 130-µm Willow Glass could be bent around a 4.4 cm cylinder, which matches the smallest radius of NuSTAR optics.

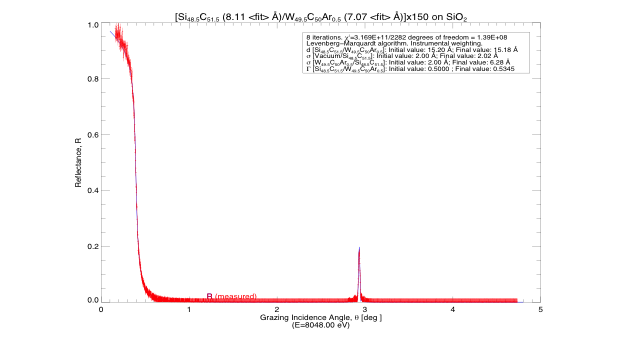

We deposited tungsten-carbide and silicon-carbide multilayer coatings with d-spacing of order 1.5 nm on both glass thicknesses with N = 150 and 300 layers, respectively. Coatings showed good adhesion to the glass. X-ray reflectivity measurements at 8 keV on N = 150 layers deposited on 200-µm Willow Glass are shown in Figure 1. Predicted and measured reflectivities were 32 and 22%, respectively, the difference potentially being due to thermal effects between the glass and the fixture. Results are very promising, and the next step would be to study the newly available 100-µm Willow Glass and optimize the deposition process as a function of glass thickness.

First Focusing Optics Design for the 90- to 140-keV Range

Among the range of applications of interest for national security, detection of weak lines, such as the x-ray lines for uranium and plutonium characteristics in a high background environment, was identified as an area for which x-ray mirrors could have an impact. One aspect we investigated was the ability to develop nested focusing optics rather than flat filtering optics in the range of energy from 90 to 140 keV, because focusing optics could help improve the signal-to-noise ratio by focusing the signal onto a smaller detector placed at the focal plane.

Several issues were identified and investigated from the multilayer coating components to the quality of axial multilayer uniformity deposited on cylindrical glass segments. We formed a collaboration with Reflective X-ray Optics, LLC (RXO), a New York company, to investigate the performance of tungsten and silicon-carbide as well as tungsten-carbide and silicon-carbide multilayer coatings with d-spacing ranging from 40 to 10 Å for hard x rays—more specifically in the energy range from 90 to 140 keV.13 (RXO has a strong track record for periodic, depth-graded, and aperiodic multilayer deposition and the capability to coat cylindrical glass segments, including some used in NuSTAR optics.) Hard x-ray reflectance versus energy measurements were made at various incidence angles, using RXO’s hard x-ray reflectometer that operates at up to 160 keV.14 Measured reflectivity matched the predicted response very well for coatings with d-spacing greater than 20 Å, and the tungsten and silicon-carbide films deposited in RXO’s coating chamber provided higher reflectance than tungsten-carbide and silicon-carbide in (almost) all cases, but especially for films having periods smaller than d of about 2 nm.

Next, the band-pass properties in the 90- to 140-keV range was evaluated for three depth-graded multilayer coatings. Reflectivities were on the order of 5 to 20% and differed from simulations. It is anticipated that aperiodic multilayers would deliver a flatter response between 15 and 20%, thus improving the multilayer performance across that range of energy. This solution was chosen for the final multilayer recipe of the focusing optics.

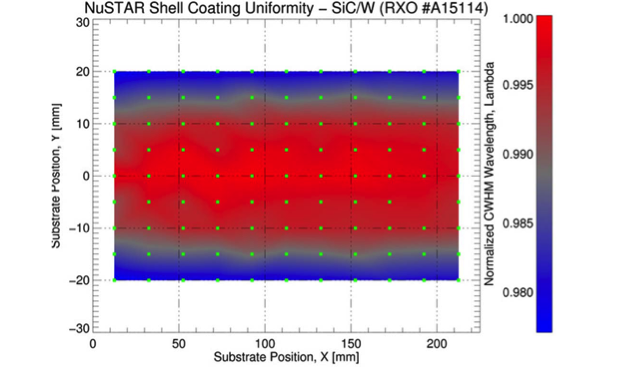

Finally, we used normal-incidence extreme-ultraviolet reflectance measurements to determine the coating uniformity of tungsten and silicon-carbide multilayers deposited on NuSTAR cylindrical shells in the RXO coating chamber. Although the coating thickness was reduced by about 2% towards the edge of the shell, the axial uniformity was excellent, below a fraction of a percent (see Figure 2).

Based on these results and on the LLNL team expertise designing highly nested focusing optics, we designed a demonstration optic corresponding to one 12-section segment of a Wolter I focusing optic for the 90- to 140-keV energy range. This demonstration optic comprised four nested layers of 30° segments of NuSTAR cylindrical glass shells within a range of angles between 1.904 and 1.962°.

First Demonstration of Hard X-Ray Mirrors in Laser–Plasma Experiments

Experiments conducted at Livermore's Titan laser demonstrated that reflective multilayer mirrors could be used as a diagnostic for high-energy-density physics experiment on four targets with high atomic numbers. The Kα line complexes of tantalum, tungsten, gold, and uranium were preferentially reflected and successfully detected. Comparisons to data acquired with a transmission crystal spectrometer showed an order of magnitude improvement in signal-to-noise ratio for the multilayer optic.15

Impact on Mission

This project is closely aligned with the Laboratory’s mission in nuclear nonproliferation. The design, development, and characterization of novel instrumentation that uses reflective hard x-ray mirrors will expand Lawrence Livermore’s capabilities to contribute to national security through detection of special nuclear materials, which also supports the core competency in nuclear, chemical, and isotopic science and technology. Our results obtained with this research positions LLNL as an expert in hard x-ray reflective optics for safeguards applications.

Conclusion

Our project resulted in several significant accomplishments:

- First demonstration of reflectivity at 508 and 644 keV at the European Synchrotron Radiation Facility.

- Development of multilayer models demonstrating that mirror reflectivity can be extrapolated at high energy from lower-energy measurements

- First demonstration of usability of Willow Glass as a potential substrate for hard x-ray multilayer coatings.

- Design of a >100 keV Walter-I nested focusing optic for safeguards applications.

- First demonstration that multilayer-coated mirrors can be used as diagnostics in a laser–plasma experiment at LLNL's Titan laser.

These results were also instrumental in obtaining a three-year NNSA award to study hard x-ray mirrors for the nondestructive assay of nuclear spent fuel, and a two-year National Aeronautics and Space Administration and Advanced Research Projects Agency award to improve platinum and tungsten measured optical properties around L edges. Additionally, this project resulted in establishing a strong collaboration with RXO, LLC, to continue research on material systems and aperiodic coatings, resulting in a DOE small-business innovation research proposal. Our work also helped establish an end-to-end set of expertise, skills, and capabilities to model, design, fabricate and assemble nested hard x-ray multilayer focusing optics, which has proven of great interest to several governmental agencies.

The next obvious steps for this research include (1) optimizing the slumping process; (2) further investigating the Willow Glass properties as a hard x-ray mirror substrate, because it could drastically cut the cost of focusing optics; and (3) building the designed optic, testing it at wavelength in a synchrotron facility, and fielding demonstration experiments.

References

- Hailey, C. J., et al., “The nuclear spectroscopic telescope array (NuSTAR): Optics overview and current status.” Proc. SPIE 7732, 77320T (2010).

- Harrison, F. A., et al.,“The Nuclear Spectroscopic Telescope Array (NuSTAR) high-energy x-ray mission.” Astrophys. J. 770, 103 (2013).

- Fernandez-Perea, M., et al., “Physics of reflective optics for the soft gamma-ray energy range.” Phys. Rev. Lett. 111, 027404 (2013). http://dx.doi.org/10.1103/PhysRevLett.111.027404

- Fernandez-Perea, M., et al.,“Ultra-short-period WC/SiC multilayer coatings for x-ray applications." Nucl. Instrum. Meth. A 710, 114 (2013).

- Brejnholt, N. F., et al., “Demonstration of multilayer reflective optics at photon energies above 0.6 MeV.” Optic. Express 22, 15364. (2014). LLNL-JRNL-652505. http://dx.doi.org/10.1364/OE.22.015364

- Schnopper, H., et al., "Lightweight thin plastic foil x-ray telescopes." Proc. SPIE 4496, 41 (2002).

- Schnopper, H., et al., "Thin-shell plastic lenses for space and laboratory applications." Proc. SPIE 5537, 82 (2004).

- Barbera, M., et al., "Thin plastic foil x-ray optics with spiral geometry." Proc. SPIE 6688, 668815 (2007).

- Taibi, A., et al., “Characterization of thin plastic foils for applications in x-ray optics technology." Proc. SPIE 6688, 66881B (2007).

- Al Husseini, M., et al., "Fabrication update on non-contact mirror slumping technology for the international x-ray observatory mirrors." Proc. SPIE 8147, 81470N-1 (2011).

- Liang, X., et al., "Electrostatic force-assisted nanoimprint lithography.” Nano Lett. 5(3), 527 (2005)

- Youn, S. W., et al., "Surface patterning of glass via electrostatic imprinting using a platinum mol." J. Nanosci. Nanotechnol. 12(4), 3181 (2012).

- Windt, D., et al., “W/SiC x-ray multilayers optimized for use above 100 keV.” Appl. Optics 42, 2415 (2003).

- Windt. D., “Laboratory-based x-ray reflectometer for multilayer characterization in the 15–150 keV energy band." Rev. Sci. Instrum. 86, 043107 (2015).

- Brejnholt, N. F., et al., "Reflective multilayer optic as hard x-ray diagnostic on laser-plasma experiment." Rev. Sci. Instrum. 86, 013110 (2015). LLNL-JRNL-664311. http://dx.doi.org/10.1063/1.4906509

Publications and Presentations

- Brejnholt, N. F., et al., Challenges in characterizing multilayer coatings for use in soft gamma-ray detection and filtering. 2013 IEEE NSS/MIC/RTSD—Nuclear Science Symp. and Medical Imaging Conf. and Room-Temperature Semiconductor X-Ray and Gamma-Ray Detectors Workshop, Seoul, Korea, Oct. 27–Nov. 2, 2013. LLNL- ABS-637594.

- Brejnholt, N. F., et al., “Demonstration of multilayer reflective optics at photon energies above 0.6 MeV.” Optic. Express 22, 15364 (2014). LLNL-JRNL-652505. http://dx.doi.org/10.1364/OE.22.015364

- Brejnholt, N. F., et al., Next generation hard x-ray/soft gamma-ray optic design and implementation. SPIE Astronomical Telescopes and Instrumentation, Montreal, Canada, June 22–27, 2014. LLNL-PROC-655710.

- Brejnholt N. F., et al., "Reflective multilayer optic as hard x-ray diagnostic on laser-plasma experiment." Rev. Sci. Instrum. 86, 013110 (2015). LLNL-JRNL-664311. http://dx.doi.org/10.1063/1.4906509

- Descalle, M. A., et al., Gamma-ray multilayer mirrors for homeland security applications. 2013 IEEE NSS/MIC/RTSD—Nuclear Science Symp. and Medical Imaging Conf. and Room-Temperature Semiconductor X-Ray and Gamma-Ray Detectors Workshop, Seoul, Korea, Oct. 27–Nov. 2, 2013. LLNL-ABS-643484.

- Pivovaroff, M. J., High reflectivity multilayers for hard x-ray and soft gamma-ray applications. (2013). LLNL-PRES-643015.