Rebecca Dylla-Spears

Overview

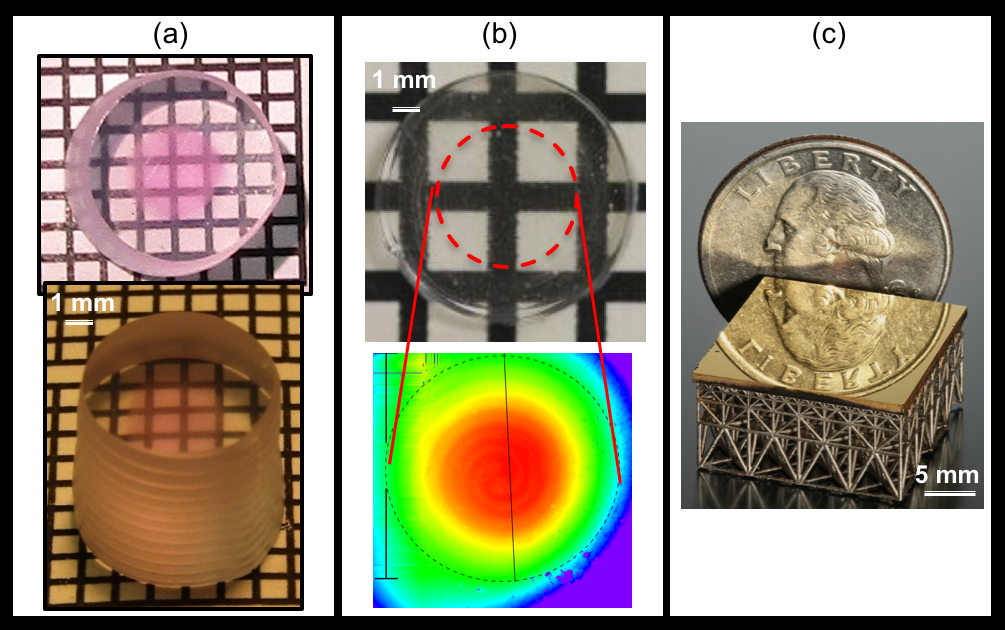

The ability to create new functionally graded optical materials using additive manufacturing has the potential to transform optical systems design by enabling the fabrication of optimal, robust, lightweight, and compact optics that are unachievable by previously demonstrated approaches. We sought to produce three different optics, each in a different material system, to demonstrate that three-dimensional (3D) printing provides a viable route to novel optics: (1) a transparent ceramic laser rod with a dopant gradient, (2) a gradient-index (GRIN) glass lens, and (3) a lightweight mirror with gradient stiffness. The laser rods and GRIN optics were prepared as compositionally tailored, low density structures (green bodies) using direct ink writing (DIW), a technique in which specially tuned pastes are blended inline at the print nozzle to achieve the desired composition at the desired location. The printed green bodies then underwent a series of tuned thermal treatments that resulted in full density, transparent components. The lightweight mirror was prepared by adhering a thin glass mirror face to an electroless nickel-plated, lightweight, stiff structural support that was built using projection microstereolithography (PSL), a technique by which complex and intricate polymeric structures can be formed by selectively crosslinking photocurable resins layer-by-layer.

Several important outcomes were achieved for each optic, including the following:

- The team produced the first 3D-printed, core-clad, and radially graded neodymium (Nd) doped yttrium–aluminum–garnet (YAG) transparent ceramic laser rods and demonstrated lasing of these rods in a commercial laser head.

- The team showed equivalence between 3D-printed silica and titania–silica glasses and commercially-produced optical-quality glasses and also demonstrated 2–5x-diffraction-limited, printed GRIN-glass lenses with a maximum index change of approximately 0.01.

- The team demonstrated a lightweight 7-cm square mirror assembly that was conventionally polishable to approximately 3-μm peak-to-valley flatness. In addition, the team identified routes to PSL-printable low expansion glass structures.

The project has thus far resulted in two filed patents and four published manuscripts and is expected to advance Lawrence Livermore National Laboratory’s interests in space and surveillance applications, as well as in compact, high-average-power laser systems.

Background and Research Objectives

The objective of this research was to prepare three different optical components with functional gradients in material properties that could not have been achieved using traditional fabrication approaches. The project took advantage of the maturation of additive manufacturing (AM) technology, as well as deep expertise in AM and optical materials housed at Lawrence Livermore National Laboratory. We chose material systems and optics that had the potential to increase the flexibility that laser and optical system designers have to reduce the size, weight, and power of optical systems, to reduce cost, and to improve system performance. Specifically, we demonstrated a laser rod with a gradient gain profile, a GRIN glass lens, and a lightweight mirror with gradient stiffness support (see figure).

Gradient Doped Laser Rod

While technologies such as single-crystal growth and glass fabrication, which are used for making laser gain media (materials within a laser that amplify the laser's optical power through energy transference), are advanced and well-developed, new approaches to manufacturing transparent ceramics offer functional opportunities not afforded by structures grown from the melt. In particular, higher doping levels, controlled compositional structures, improved fracture toughness, thermal-shock resilience, and improved resistance to laser damage are obtained with ceramics (Ge et al. 2013, Ikesue and Aung 2008). For this effort, we targeted a widely employed laser-rod configuration for improvement in energy conversion efficiency into the desired fundamental Gaussian laser mode (electromagnetic field pattern).

GRIN Glass Lens

Conventionally, glass optics are prepared from melt-produced glass with uniform composition, and the optical surfaces are shaped via precise finishing techniques to achieve the desired optical effect. GRIN optics instead use composition-based change in the refractive index to affect the path of light through the optic. GRIN optics are prepared by the diffusion of ions into solid glass by submerging them into molten salt baths (Visconti and Bentley 2013). Hence, the range of compositions and thus index differential, as well as the GRIN profiles and optic sizes achievable, are limited. AM provides additional degrees of compositional freedom compared with the state of the art. Several melt-based additive manufacturing approaches for glass have been demonstrated outside Livermore in recent years, including resistive or laser heating of glass powders or glass rods and filaments (Luo et al. 2017, Marchelli et al. 2011). Though some of these methods have resulted in transparent glass structures, all used a single glass composition, and none demonstrated that the printed glass would meet the quality required for optics. This was a major outstanding question because the refractive index of glass is highly dependent on its thermal history. For this reason, we chose to pursue a two-step approach to GRIN glass formation, first using DIW to create a compositionally graded green body, which we then converted to transparent glass through a series of heat treatments. While DIW mixing technology had been demonstrated at Livermore with polymers, the team had to develop feedstocks, inks, and heat treatments compatible with preparing transparent, crack-free glass, as well as inks and methods for changing the refractive index with the precision required of optics.

Lightweight graded density mirror

Ultralightweight mirrors are of value for space applications, fast scanners, and portable optical systems for which saving weight is of paramount importance. While such mirrors can be made from light, stiff materials such as beryllium or silicon carbide, these materials are expensive and very difficult to polish. Glass mirrors are far easier to polish and are typically lightweighted by removing as much material from the glass structure as possible, such that the mirror will continue to hold its surface figure (shape) to within hundreds of nanometers, which is critical to its optical function during transport and use. When lightweighted to the extreme, however, these mirrors can suffer from an effect called print-through, where the structure underlying the mirror is imprinted into the mirror face causing face deformation during polishing (Döhring et al. 2007, Peters et al. 2001).

Additively manufactured coated polymer lattices, as first demonstrated on a 1-cm scale by Zheng and coworkers at Livermore (Zheng et al. 2014), offered the possibility to quickly and easily produce lightweight, ultrastiff mirror backings, where struts could be added to increase stiffness, thereby only adding weight where needed to compensate for loads. We sought to make large, lightweight, lattice-backed mirrors with structures that could be optimized for conventional full-aperture glass polishing.

Impact on Mission

The ability to produce novel optics by AM has potential impact on several missions of interest to Lawrence Livermore National Laboratory, as well as to potential sponsors. For example, Livermore has a strong transparent ceramics capability, having invented several new ceramic scintillators, and through this project, we have expanded into laser gain media. This research opens the door to a wide range of ceramic optics for defense and non-proliferation applications. Our research in gradient index glass AM has potential application to fiber laser and space programs for the potential to prepare novel sensing optics and fiber laser preforms. Further, the DOD and their vendor base has strong interest in lightweighting, either through a reduction in the number of glass optics afforded by the design and manufacture of novel optics, or by directly lightweighting structures and components.

Livermore is now seen as a leader in the field of 3D-printed optics and has filed patent applications on printed laser gain media, as well as on printed tailored glasses.

Conclusion

We have demonstrated that additive manufacturing is a viable route to the production of novel optics with gradients in composition and structure. We expect that the proof-of-concept optics will spur an innovation in optics design, with concepts for optics with profiles, material property changes, and materials falling well outside of the particular use-cases that we originally demonstrated. Interest in Livermore’s transparent ceramics capability has led to seed funding from the DOD Joint Technologies Office and multiple discussions with potential industrial partners to continue our work in ceramic-based gain media. Future research will explore inkjet printing as an alternative for forming graded transparent ceramic structures. The use of PSL technologies for mirror supports and also for custom glass optics with intricate shapes remains of interest in the space optics community, both internally and externally. Although no specific partnerships have been formed to date, our research in formulations for photocurable glass could be furthered by collaborating with an industrial partner. Finally, our research in compositionally graded, additively manufactured glasses will be taken in new directions through another research project, the purpose of which is to expand the glass compositions that can be accessed via DIW. We are also in active discussions with several potential industrial partners and have formed some beneficial university collaborations as well. Because of the high level of interest in the AM of optics, we will continue to pursue the partnerships required to advance the technology to a higher level of readiness, and we expect that at least some of the technologies will find use, at least initially, in less demanding applications than optics.

References

Döhring, T., et al. 2007. Proceedings of the Conference on Optical Materials and Structures Technologies III, 6666: 666021-666029.

Ge, L., et al. 2013. "Fabrication of Composite YAG/Nd:YAG/YAG Transparent Ceramics for Planar Waveguide Laser." Int. J. Refract. Met and Hard Matls., 39: 44–52.

Ikesue, A. and Y.L. Aung. 2008. "Ceramic Laser Materials." Nature Photonics, 2: 721–727.

Luo, J., et al. 2017. "Additive Manufacturing of Transparent Soda-Lime Glass using a Filament-Fed Process." J. Manuf. Sci. Eng., 139: 61006.

Marchelli, G., et al. 2011 "The Guide to Glass 3D Printing: Developments, Methods, Diagnostics and Results." Rapid Prototyping. J., doi: 10.1108/13552541111124761.

Peters, B.R., et al. 2001. Proceedings of the Conference on Lidar Telescopes for Industry and Environment Monitoring, 4153: 359–365.

Visconti, A.J. and J.L. Bentley, 2013. "Fabrication of Large-Diameter Radial Gradient-Index Lenses by Ion Exchange of Na+ for Li+ in Titania Silicate Glass." Optical Engineering, 52 (11): 112103.

Zheng, X., et al. 2014. Science, 344 (6190): 1373–1377.

Publications and Presentations

Destino, J. F., et al. 2017. "Novel Sol-Gel Derived TiO2-SiO2 Particle Systems for Direct Ink Writing Compositionally Tailored GRIN Glasses." American Chemical Society National Meeting, San Francisco, CA, March 2017. LLNL-PRES-728230.

——— . 2018. "3D Printed Optical Quality Silica and Silica-Titania Glasses from Sol-Gel Feedstocks." Adv. Mater. Tech., 8 Jan. 2018. doi: 10.1002/admt.201700323. LLNL‐JRNL‐737841.

Dudukovic, N. A., et al. 2017. "Rheological Characterization of Colloidal Silica Suspensions for 3D Printing of Optical Glass Monoliths." The 88th Annual Meeting of The Society of Rheology, Tampa, FL, February 2017. LLNL-PRES-723093.

——— . 2017. "Additive Manufacturing of Lightweight Mirrors." Postdoc Symposium, Lawrence Livermore National Laboratory, Livermore, CA, June 2017. LLNL-POST-732358.

——— . 2018. "Additive Manufacturing of Lightweight Mirrors." SPIE Defense + Commercial Sensing Orlando, FL, April 2018. LLNL-PRES-749402.

——— . 2018. "Tuning Nanoparticle Suspension Rheology for 3D Printing of Silica-Titania Glass." Pacific Rim Conference on Rheology, Jeju, Korea, June 2018. LLNL-PRES-752637.

——— . 2018. "Tuning Nanoparticle Suspension Rheology for 3D Printing of Silica-Titania Glass." The 29th Annual International Solid Freeform Fabrication Symposium, Austin, TX, August 2018. LLNL-PRES-756302.

——— . 2018. "Additive Manufacturing of Lightweight Mirrors." The 29th Annual International Solid Freeform Fabrication Symposium, Austin, TX, August 2018. LLNL-PRES-756301.

——— . 2018. "Multimaterial 3D Printing of Silica-Titania Glass: Predictive Tuning of Suspension Rheology." The 90th Annual Meeting of The Society of Rheology, Houston, TX, October 2018. LLNL-PRES-759580.

Dylla-Spears, R. J., et al. 2016. "Silica Glass with Tailored Refractive Index Profile Using Direct Ink Write Additive Manufacturing." Seminar. Livermore, CA. October 2016. LLNL-PRES-713197.

——— . 2017. "3D Printed Optical Components with Compositional and Structural Gradients." SPIE Optifab, Rochester, NY, October 2017. LLNL-PRES-739848.

———. 2018. "Fabrication of Silica Glasses with Tailored Compositions by 3D Printing." Glass & Optical Materials Division Meeting, American Ceramic Society, San Antonio, TX, May 2018. LLNL-PRES-751458.

——— . 2018. "3D-Printed Optical Quality Glasses Toward the Additive Manufacturing of Optics." Gordon Research Conference on Solid State Studies in Ceramics, South Hadley, MA, August 2018. LLNL-PRES-756304.

——— . 2018. "Additive Manufacturing of Glass Optics." American Precision Optics Manufacturers Association Technical Workshop, Livermore, CA, October 2018. LLNL-PRES-759949.

——— . 2018. "Additive Manufacturing of Glass Optics." 4th Additive Manufacturing JOWOG, October 2018. LLNL-PRES-759752.

Jones, I. K., et al. 2018. "Direct Ink Write Fabrication of Transparent Ceramic Gain Media." Optical Materials, 75, 19–25, January 2018. LLNL-JRNL-736260.

Nguyen, D. T., et al. 2017. "3D Printed Transparent Glass." Adv. Mater., 2017, 29,1770185. LLNL-JRNL-720419.

Payne, S. 2017. Laser Gain Media Fabricated Via Direct Ink Writing (DIW) and Ceramic Processing. U.S. Patent Application, June 2017.

——— . 2017. "Additively Manufactured Gain Media for Lasers." Electrochemical Society, September 2017. LLNL-PRES-739135.

Sasan, K., et al. 2018. "Developing 3D-Printed Optical Glasses from Sol-gel Feedstocks." Postdoc symposium, Lawrence Livermore National Laboratory, Livermore, CA, June 2018. LLNL-POST-752543.

——— . 2018. "Developing 3D-Printed Optical Glasses from Sol-Gel Feedstocks." 256th ACS National Meeting and Exposition, Boston, MA, August 2018. LLNL-CONF-756177.

Seeley, Z. 2018. "Ceramic Gain Media with Tailored Doping Profile." American Ceramic Society, San Antonio, TX, May 2018. LLNL-PRES-751696.

Yee, T. D., et al., 2018. “3D Printed Transparent Glass with Gradient Properties.” MRS Fall Meeting, Boston, MA, November 2018. LLNL-PRES-761977.