Brian Giera (17-ERD-037)

Executive Summary

This project is developing a machine-learning algorithm for vision-based control of additive-manufacturing processes to automatically detect problems and implement rectification strategies, thereby improving quality while reducing time and cost. This technology supports stockpile stewardship and Inertial Confinement Fusion programs, which require rapid build qualification for the large-scale production of high-quality parts.

Project Description

Additive manufacturing (AM) describes a host of fabrication technologies wherein a digital set of design and processing instructions are fed to a system that builds objects in a layer-by-layer fashion. Existing state-of-the-art AM methods for controlling the printing system do not allow for the build instructions to be adjusted according to in situ process data collected by sensors, such as pressure gauges and high-speed cameras mounted to the AM system that monitor the build process. Rather, AM devices rely solely on open-loop control of the print process that blindly follows pre-computed process plans. At present, AM methods lack automated detection and rectification of manufacturing defects that are necessary for rapid build qualification, tighter tolerances, and higher yields. Recent advances in the development of machine learning (ML) algorithms for vision-based control offer a way for the system to make real-time adjustments to the processing instructions based on feedback from sensor data. An appealing characteristic of ML algorithms is that they dispense with the need for precisely modeling the environment. Instead they leverage direct experience gathered from real executions to learn vision-guided control of the printing process. We are developing a control algorithm based on ML that automatically detects and implements rectification strategies during AM processes. Because these ML algorithms are agnostic to the data streams or the apparatus they control, the same coding framework can be used for rapid closed-loop control of selective laser melting (SLM), direct ink write (DIW), and other AM processes. A successful implementation will reduce time and cost during the build process by automating quality and quality-control assessment.

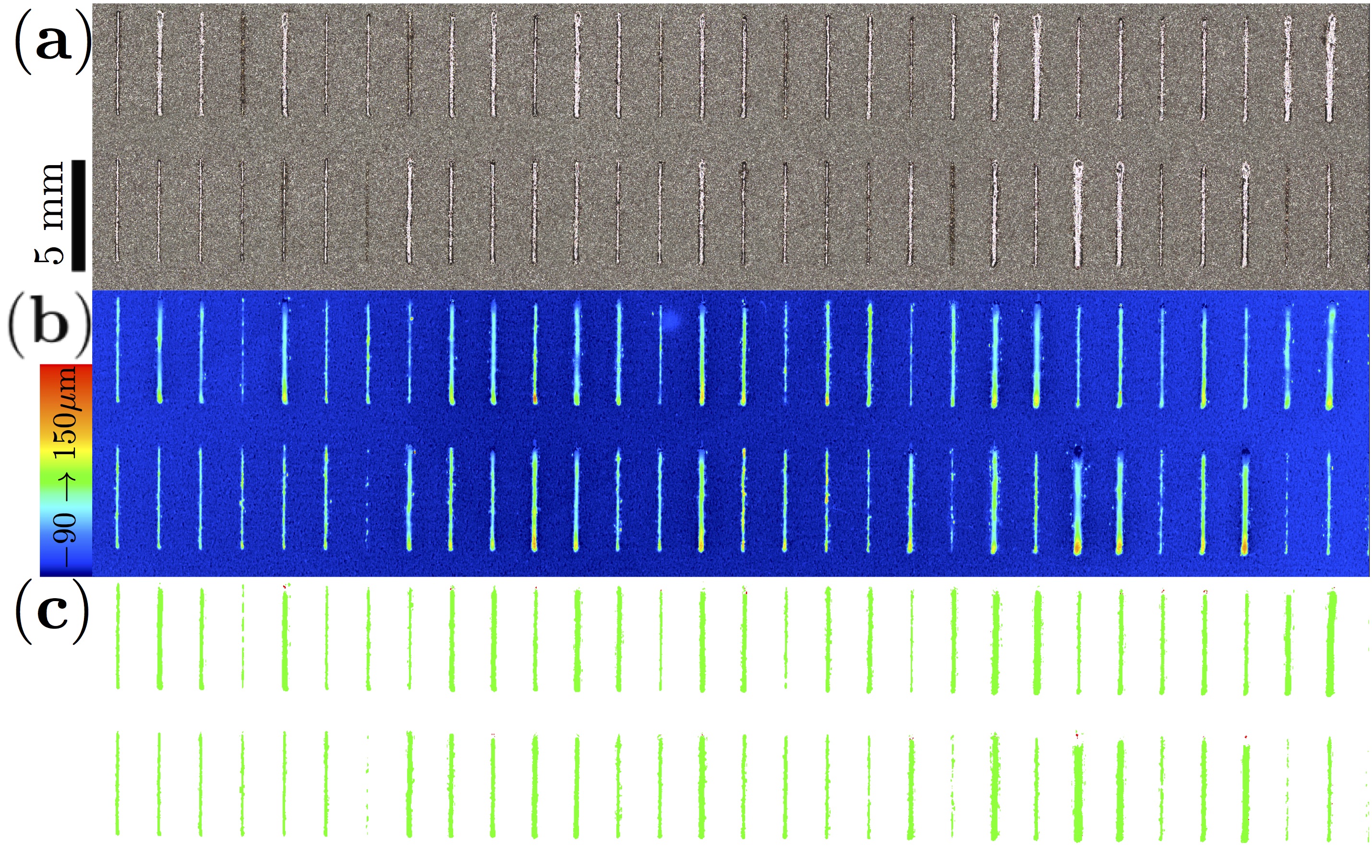

We are developing ML algorithms that will enable closed-loop control within at least two candidate AM systems: SLM and DIW. The final material properties of parts made via these techniques are sensitive to the design and process parameters. The large material set available to selective laser melting and DIW poses a significant challenge to identify optimal operating parameters and in situ control mechanisms needed to produce parts rapidly and reliably with the desired properties. SLM and DIW AM process data have already been gathered under a variety of operating conditions and builds. These operating conditions include known feasible operating conditions (during which desirable AM print data are generated), as well as regions outside of this feasible space (during which undesirable AM print data are generated). For the case of SLM, in situ data is represented by high-speed imaging and pyrometer readings focused at the melt pool, while ex situ data measurements are taken by a profilometer that characterizes the surface roughness of the welds. We aim to automate defect detection and qualification of additively manufactured parts using hybrid convolutional and recurrent network models that transform in situ sensor data into actionable information as a part of the build process.

Mission Relevance

Our research supports Lawrence Livermore National Laboratory's high-performance computing, simulation, and data science core competency by developing new capabilities for ML associated with process control of data-intensive AM. This work also supports the Laboratory's advanced materials and manufacturing core competency by automating detection and rectification of AM defects, which enables rapid build qualification and data for optimal selection of process parameters. SLM and DIW AM methods are relevant to the needs of the stockpile stewardship and Inertial Confinement Fusion programs, which require rapid build qualification for the large-scale production of high-quality parts. By supporting these programs, this research addresses the DOE goals of maintaining nuclear and energy security.

FY17 Accomplishments and Results

In FY17, we (1) refined in situ SLM process data collection and ex situ measurements of tracks created under many conditions; (2) collaborated with UC Berkeley to encode an algorithm that rapidly generates video labels of track width, roughness, etc. required by the ML algorithm to improve track-quality assessment in situ; (3) began collecting data for DIW and fused-deposition model printers, including thermal-image data from which an ML algorithm will assess print conditions to modulate toolpaths; (4) began exploring ML-based, rapid-closed loop control of microfluidics, which uses the same data-collection methods and ML algorithms as the above examples, but is easier to implement; and (5) began preparing a paper for publication and a patent application.

Publications and Presentations

Giera, B. 2017. "Machine Learning Based Monitoring of Advanced Manufacturing." LLNL-PRES-736249.

——— 2017. "Machine Learning Based Monitoring of Advanced Manufacturing." LLNL-PRES-72953.2.

——— 2017. "Machine Learning Based Monitoring of Microfluidics." LLNL-PRES-730679.

——— 2017. "Machine Learning of Microfluidic-Based Encapsulation." LLNL-POST-731978.