Jeffrey Bude | 16-ERD-016

Overview

Pulsed-laser material modification can lead to material and component failure in advanced laser systems or sensitive defense-related systems. Laser systems for scientific applications and national security missions are often designed to operate under conditions of extreme optical intensity, high average power, or flux density. This can result in degradation and damage to key optical components, limiting system performance and imposing severe constraints on operation. General modes of damage are related to how different materials absorb energy and how they respond to this energy deposition. For laser-based machining, laser-material interactions control the removal (ablation) rate and removal efficiency while damage modes affect throughput, collateral damage, and precision. In this research project, we integrated laser material testing, advanced diagnostics, characterization, and simulation to develop a more rigorous theoretical and experimental understanding of pulsed-laser processes in dielectrics, semiconductors, metals, and ion-doped glasses relevant to damage, material failure, ablation physics, and pulsed-laser machining.

Background and Research Objectives

The primary goal of this research was to clarify the physics of pulsed-laser material interactions relevant to advanced laser systems, laser-based material processes, and directed energy vulnerabilities. We achieved this through experiments, modeling, and simulation designed to evince the damage limits of general classes of materials: optical materials (exit surface damage and bulk damage), metals, and semiconductors. This project was organized in three main tasks designed to elucidate specific, important aspects of each material class. Specifically, we studied (1) bulk damage in ion-doped filter glass, (2) exit surface sub-bandgap damage in optical material, and (3) ablation physics in semiconductors and metals.

Filter glasses can be used as optical limiters to protect important components in an optical system. For instance, Ce-doped silica glass (“blue blocker” glass) has been proposed as a new optic type on the National Ignition Facility (NIF) designed to absorb unwanted ultraviolet (UV) light back-reflected from a target so that it doesn’t damage mirrors designed to operate in the infrared. While the potential for the glass is high, there has not been a study of bulk damage modes intrinsic to this material. We performed such a study.

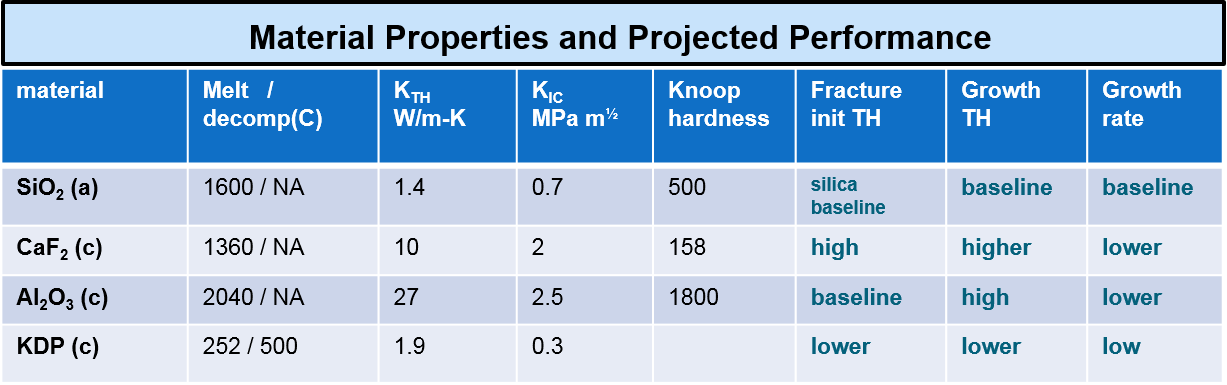

Exit surface damage in transparent optical materials has been the topic of many previous studies, especially those focused on damage initiation and growth in fused silica (Bude et al. 2014a, 2014b; Suratwala et al. 2011; Carr et al. 2010; Miller et al. 2010; Norton et al. 2006; Negres et al. 2010, 2014). While the damage is initially small, it grows significantly with additional laser pulses. Ultimately, damage growth limits the lifetime of optics. In this project, we significantly extended the scope of previous investigations of damage growth to a variety of other materials to better understand the role of material properties, the features of damage sites related to the growth threshold and the growth rate, and the behavior of growth for large numbers of shots (see table below).

Relevant material properties of materials chosen for the 3ω damage growth study; also shown are the projected fracture initiation thresholds, growth thresholds, and growth rates based on previous models of damage growth.

Finally, we spent significant effort studying ablation physics in metals and semiconductors as it pertains to material processing and material damage. Short-pulse laser-matter interaction has gained considerable interest over the last two decades as pulsed laser technologies have extended the capabilities of laser-driven material processing and research, including advancements in high-precision cutting and drilling (Chichkov et al. 1996, Wellershoff et al. 1999, Harzic et al. 2002), surface nano-structuring (Vorobyev and Guo 2007, Zhao et al. 2007, Dai et al. 2012), nanoparticle synthesis (Barcikowski et al. 2007, Perriere et al. 2007, Haustrup and O’Connor 2012, Miotello and Patel 2013), high speed imaging (Dausinger et al. 2004), and laser-induced plasma spectroscopy (Hannaford 2004). Much of the research to date has been focused on material processing for the ultrashort sub-picosecond pulse regime (~100–500 fs full-width at half-maximum pulse), particularly for fluences below ~10 J/cm 2 (attainable by high-repetition-rate, low-pulse-energy lasers) and near-infrared wavelengths of ~800–1000 nm (easily produced by common short-pulse gain media). Far less attention has been given to picosecond pulsed laser ablation, which offers advantages in terms of reduced laser system complexity and cost compared to current femtosecond technology (Kleinbauer et al. 2005), while still providing similar capability in terms of low collateral damage, limited heat affected zones, and the ability to process both metals and dielectrics. In order to better understand the physical processes governing picosecond pulsed laser ablation, we coupled experimentation with multi-physics radiation hydrodynamic simulation to study material removal in two metals (Al and 316L-grade stainless steel) and a semiconductor (undoped crystalline Si <100>) at laser wavelengths of 355 nm and 1064 nm over a fluence range of 0.1–50 J/cm 2 .

This research highlighted melt cavitation as an important process involved in efficient material removal by UV picosecond laser pulses. Based on these observations, we sought ways to enhance removal efficiency and material failure in metals and semiconductors by exploiting hydrodynamic instabilities in the melt through (1) the excitation of resonant capillary wave instabilities by modulated continuous-wave laser light, and (2) multi-laser approaches that use double pulses from two different laser sources to excite both melt cavitation and capillary wave-induced liquid jet ejection. Both methods were successful in increasing the efficiency of material removal.

Impact on Mission

The progress we made understanding bulk damage in ion-doped glasses will impact the design of blue-blockers to suppress UV back-reflections in target experiments on NIF or other high-energy UV laser systems. The advances we made understanding damage growth in a general class of optical materials supports the design of advanced laser systems operating at both high-average-power and high-pulse energies. Both efforts extend the Laboratory’s core competency in lasers and optical science. Progress in both these areas can also provide guidance with respect to directed-energy vulnerabilities, thus supporting Laboratory efforts in directed energy.

The progress we made understanding the physics of ablation, including unconventional ablation modes that exploit instabilities in the melt, will enhance the laboratory's core competency in advanced materials and manufacturing. The multi-laser, high-impulse ablation mechanism studies developed in this research exceed by a good margin the efficiency of existing laser drilling and cutting approaches. Taking advantage of these protocols will stimulate new laser concepts, further advancing the Laboratory's core competency in laser and optical science. The progress we made modeling the physics of ablation for these studies has stretched models in ALE3D and HYDRA (Livermore-developed modeling and simulation codes) beyond their typical applications. Knowing how and when to use particular models and codes for these purposes advances the Laboratory’s core competency in modeling and simulation. Also, the discoveries we've made during this project will also advance missions in directed energy. Taken as a whole, the project has grown both capabilities and staff in the important area of laser-material interaction physics.

Conclusion

This project touches many existing programs at the Laboratory and has already forged inter-directorate collaborations. We have also leveraged the results from this research into a strategic partnership project with good prospects for growth. Further development of the intellectual property created here can serve as the basis for future industrial collaborations.

References

Barcikowski, S., et al., 2007. "Properties of Nanoparticles Generated During Femtosecond Laser Machining in Air and Water." Appl. Phys. A 87, 47.

Bude, J., et al. 2014a. "High Fluence Laser Damage Precursors and Their Mitigation in Fused Silica." Opt. Exp. Vol. 22, 5839, LLNL-JRNL-648575.

Bude, J., et al. 2014b. "Silica Laser Damage Mechanisms, Precursors and Their Mitigation." SPIE Laser-Induced Damage in Optical Materials : 9237, 92307S, Sept. 2014.

Carr, C. W., J. D. Bude, and P. DeMange, 2010. "Laser-Supported Solid-State Absorption Fronts in Silica." Physical Review B 82 , 184304.

Chichkov, B.N., et al. 1996. "Femtosecond, Picosecond and Nanosecond Laser Ablation of Solid." Appl. Phys. A63, 109.

Dai, Y., et al. 2012. Appl. Phys. A 106, 567.

Dausinger, F., F. Lichtner, and H. Lubatschowski. 2004. Femtosecond Technology for Technical and Medical Applications, Springer.

Hannaford, P. 2004 Femtosecond Laser Spectroscopy , Springer.

Haustrup, N. and G.M. O’Connor. 2012. "Impact of wavelength dependent thermo-elastic laser ablation mechanism on the generation of nanoparticles from thin gold films." Appl. Phys. Lett . 101, 263107.

Kleinbauer, J., R. Knappe, and R. Wallenstein. 2005. "A Powerful Diode-Pumped Laser Source for Micro-Machining with Ps Pulses in the Infrared, the Visible and the Ultraviolet." Appl. Phys. B 80, 315

Le Harzic, R., et al. 2002. "Comparison of Heat-Affected Zones Due to Nanosecond and Femtosecond Laser Pulses Using Transmission Electronic Microscopy." Appl. Phys. Lett. 80, 3886.

Miller, P. E., et al. 2010. "Fracture-Induced Subbandgap Absorption as a Precursor to Optical Damage on Fused Silica Surfaces." Optics Letters 35, 2702-2704.

Miotello, A. and N. Patel. 2013. "Pulsed Laser Deposition of Cluster-Assembled Films for Catalysis and the Photocatalysis Relevant to Energy and the Environment." Appl. Surf. Sci . 278, 19.

Negres, R., et al. 2010. "Growth Behavior of Laser-Induced Damage on Fused Silica Optics Under UV, Ns Laser Irradiation." Opt. Exp . 18, 19966.

——— . 2014. "Growth Model for Laser-Induced Damage on the Exit Surface of Fused Silica Under UV, Ns Laser Irradiation." Opt. Exp. 22, 3824.

Norton, M. A., et al., 2006. "Growth of Laser Damage on the Input Surface of SiO 2 at 351 nm." Proceedings of the SPIE - The International Society for Optical Engineering 6403, 64030L.

Perriere, J., et al. 2007. J. Phys. D: Appl. Phys. 40, 7069.

Suratwala, T. I., et al. 2011. "HF-Based Etching Processes for Improving Laser Damage Resistance of Fused Silica Optical Surfaces." Journal of the American Ceramic Society 94, 416-428.

Vorobyev, A.Y. and C. Guo. 2007. "Nanoparticle Formation by Femtosecond Laser Ablation." Appl. Phys. A 86, 321.

Wellershoff, S.S., et al., 1999. "The Role of Electron–Phonon Coupling in Femtosecond Laser Damage of Metals." Appl. Phys. A 69, S99.

Zhao, Q.-Z., S. Malzer, and L.-J.Wang. 2007. "Self-Organized Tungsten Nanospikes Grown on Subwavelength Ripples Induced by Femtosecond Laser Pulses." Opt. Express 15, 15741.

Publications and Presentations

Demos, S. G., et al. 2018. "Laser-Induced-Damage Mechanisms Under Nanosecond Laser Irradiation in Absorbing Glasses." SPIE Laser Damage, Boulder, CO, Sept. 2018, LLNL-PRES-758028.

Ly, S., et al. 2018. "Shockwave Enhanced Ablation." HPLA18, Santa Fe, NM, March 2018. LLNL-POST-748345.

Norton, M. A., et al. 2018. "Experimental Study of Growth on Exit Surface of Various Transmissive Materials at 1053 nm and 351 nm." presented at SPIE Laser Damage, Boulder, CO, Sept. 2018. LLNL-POST-758448.

Rubenchik, A.M., et al. Enhancement of Laser Material Processing via Modulation of Laser Light Intensity. ROI IL13305. Provisional patent application 62/647521.

Rubenchik, A.M., et al. Laser Drilling and Machining Enhancement Using Gated CW + Short Pulse Lasers. ROI IL13306. Provisional patent application 62/647544.

Rubenchik, A.M., et al. 2018. "Unconventional Ablation." HPLA18, Santa Fe, NM, March 2018. LLNL-CONF-748270.

Rubenchik, A.M., et al. 2018. "Laser Ablation of Metals using Periodically Modulated Intensity." HPLA18, Santa Fe, NM, March 2018. LLNL-CONF-748270.