Manyalibo Matthews (14-ERD-098)

Abstract

Surface contamination has long been recognized as a performance-limiting issue in many areas of technology. While debris accumulation on optical surfaces is generally problematic because it causes light scattering, diffraction, and obscuration, the impact to performance takes on new dimensions when considering optics for high-power laser systems. In these systems, surface contamination generated through optical processing and handling can lead to damage initiation and local fracture that, if left uncorrected, can limit optic lifetime in a pulsed laser system after several successive laser shots. The laser processing of large, fused-silica optics and optical damage cross-contamination can also introduce debris, compounding the issue further. Similar effects have also been associated with silica–hafnia dielectric multilayer stacks used as high-reflector optics as well. In this project, we have investigated the interaction of microscale metallic and glass particles bound to optical surfaces with nanosecond laser pulses at 1064 and 355 nm. Our in situ experimental platform has allowed direct measurements of the particle velocity, plasma formation, and the kinetics of the ejected molten material. Large-aperture damage tests were also performed to assess damage probabilities and probe the stochastic nature of particle-induced damage events. Finite-difference time-domain methods, Fourier beam propagation, and ray tracing were used to understand the effects of particle shape and particle-induced surface pitting on beam propagation. By varying the combination of particle and substrate materials, we have been able to gain important insights into the governing mechanisms of laser–particle interactions that could lead to improvements in high-power laser optics designs.

Background and Research Objectives

Acting as couplers of laser energy onto the optic surface, contaminant particles in an optical system can cause damage ranging from moderate system degradation from optical scattering loss, to catastrophic failure.1-11 A comprehensive study was needed to clarify the energy coupling mechanisms involved and lead the way towards effective mitigation techniques.12,13 In this project we investigated the morphological and chemical evolution of surface-bound, micrometer-scale particles in the presence of high-power laser irradiation and their interaction with an underlying optical surface. Fused silica, sapphire, and multilayer dielectric coatings were the primary optical materials used to host the surface-bound particulates. The primary objectives of our study were as follows:

- Develop optical and spectroscopic diagnostics to study microscale laser–particle interactions at nanosecond timescales

- Execute experiments with different pairing of particles and substrates, propagation geometry, and laser beam conditions

- Analytically or numerically model laser absorption, material response, and subsequent effects on laser beam propagation

- Explore practical mitigation strategies including pre-pulse laser cleaning, chemical passivation or coatings

Scientific Approach and Accomplishments

The approach taken in this study is based on developing a suite of experimental and computational tools that can be used to examine particle-driven damage events in situ and under a wide variety of conditions. The probability of damage for both fused-silica optics and dielectric mirrors contaminated with metal and glass particulates was measured and analyzed. Theoretical analysis was used to rationalize the results of laser–particle-induced damage. Highlights of the accomplishments of this comprehensive study are presented below.

Due to the generally greater impact of plasma generation on the exit surface, damage initiation into a fused-silica optic surface tends to be more likely on the exit surface.14 For this reason, more attention has been given to exit surface contaminant-driven damage initiation but little attention given to particle–surface energy coupling. In particular, the degree of melting/pitting following a laser cleaning event compared with the more classic fracture-type damage has not been fully assessed. While the contaminant may have been removed, the shallow features in the surface that remain can lead to various levels of propagated intensity modulation due to incident phase modulation which, in turn, may lead to damage.10,11

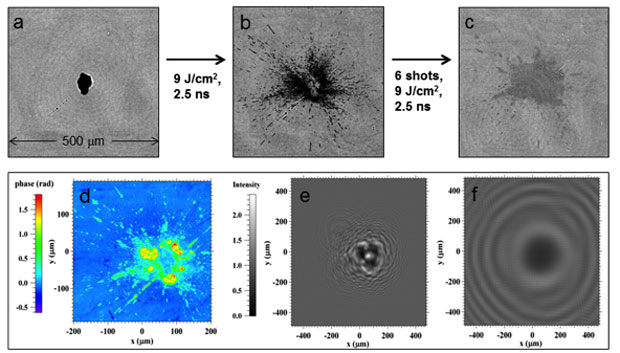

An example of this effect is shown in Figure 1 (a–c), where polymer particle contamination leads to shallow ablation pits under pulsed laser irradiation. The image in (c) shows a faint pitted region after 6 laser pulses, although the morphology was essentially constant for these particles through laser pulses 4–6. While only acetal homopolymer (Delrin) is shown, metallic particles behaved similarly in terms of pitting depths and material dispersal, while the PET-G and glass particles pitted less and dispersed more readily.

Figure 1(d–f) shows the simulated phase at z = 0 [(d)] and predicted field intensity in the near field at 10 mm [(e)] for the laser-induced phase object corresponding to (c). Bearing in mind that the phase map is inversely related to the surface height, (d) clearly reflects the initial material spreading behavior shown in (b) (and observed for aluminum and steel), which tended to leave a locally raised center (depressed phase) relative to the pitted areas. As compared to the z = 10 mm intensity pattern consistent with Fresnel diffraction, which shows a ~2 × intensification that could cause exit-surface damage on a 10-mm thick optic, the z = 100 mm [(f)] Fraunhofer diffraction in the far field is only ~1.1 × and less likely to cause damage. This correlation of particle size, material type, and laser parameters with subsequent beam modulation can be useful in guiding systems designs to allow optics to stay outside likely intensification positions.

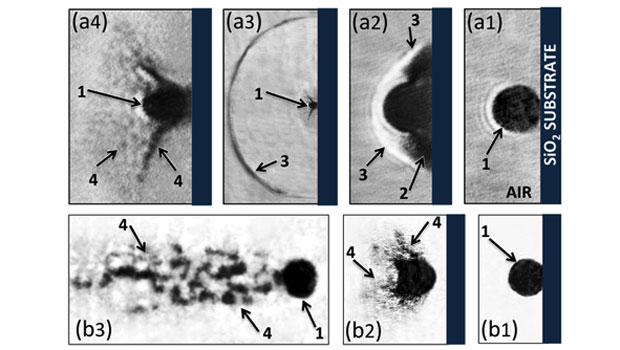

Unlike the input surface, particles ablated from the exit surface can be propelled away from the surface under the action of expanding plasma.3 Generally, the dynamics of laser–microparticle interaction involve high gradients of pressure, temperature, and corresponding changes to thermodynamic material properties, plasma formation, and aerodynamic effects, necessitating time-resolved measurements. Figure 2 displays shadowgraphy measurements capturing the moment that metal particle contaminants are ablated by the laser pulse and ejected away due to plasma expansion and recoil momentum. The top row (a series) shows the result for a ~10 J/cm2, 7-ns-long laser pulse where the initial plasma expansion around the particle is seen [(a2)] as well as the shock front and material spray captured at later times [(a3) and (a4)]. The bottom row (b series) shows that at higher fluences (~100 J/cm2), the plasma/gas expansion is strong enough to spray metal material into a narrow jet around the particle as it is ejected.

Because plasma is generated during the ablation/ejection process, it is possible to capture the spectrum of the plasma emission to gain additional information about the ablation/pitting/damage process.6 Figure 3(a) shows the plasma (electron) temperature derived from a line-to-continuum analysis of the plasma spectrum for iron (Fe) atoms in stainless steel 316L (inset). As shown, a decrease in plasma temperature vs delay time is observed, consistent with an adiabatic expansion of plasma/gas as cooling proceeds after the initial 7-ns laser pulse. More interestingly, by tuning our spectrometer to capture both Fe atomic lines emitted from the particle surface and silica (Si) atomic lines emitted from the substrate, we are able to probe temperature inhomogeneities in the plasma, as shown in Figure 3(b). From Figure 2 it is clear that the plasma generated from the plasma of Fe species is expanding during a time at which the particle has not traveled far, implying that the plasma at the silica–steel interface may be confined. Figure 3(b) appears to confirm this assertion since the temperature of the Si species close to the interface is higher than that derived from the Fe, which is emitted across a wider area of (unconfined) steel surface.

Similar to the laser-induced shallow sites produced on the input surface discussed earlier, ablation of particles bound to the output surface also created shallow (~10s to 100s of nanometers deep) pitting and/or optical damage.7,9 A remarkable finding of our study of exit-surface damage was that, while opaque particles (e.g., metallic) on the input surface ultimately posed the most danger for an optic, as compared to semi-transparent particles (e.g., glass), the opposite was true on the exit surface. That is, glass particles ablated on the input surface tended to eject away and not cause catastrophic (i.e., fracture-type, growing) damage, while glass particles on the exit surface tended to explode towards the surface and create stochastic, microfractures, which grew upon subsequent shots, leading to catastrophic damage.1

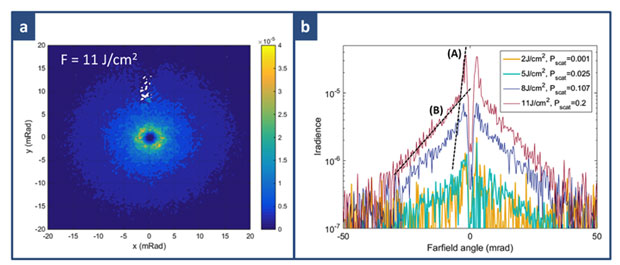

In contrast, metal particles on the exit surface led deterministically to micropits or shallow sites above some threshold (~2 J/cm2, 351 nm at 5-ns pulse length). While not leading to catastrophic damage, large ensembles of these micropits, created after many optic recycles in a large optical system like NIF, can lead to system degradation due to optical loss from scattering.7-9 A numerical simulation was used to estimate the impact of micropit scattering ensembles, and we developed a test bench to measure scattering in test samples to validate our modeling. Figure 4 shows the results of scattering measurements from fused-silica samples first contaminated with ~5-mm aluminum spherical particles, then irradiated with 3 pulses of 351 nm, 3-ns-long laser light at varying fluence levels. Figure 4(a) shows the raw far-field scattering pattern from our f/20 optical system in which the micropitted optic is placed in the near field; a perfectly non-scattering surface would allow all light passing through the f/20 lens to focus through the central pinhole, shown as the dark central core in (a). Figure 4(b) shows scattering lineouts as a function of angle for 2, 5, 8 and 11 J/cm2 fluence levels and indicates a larger amount of scattering at higher fluences, both due to more particles above pitting threshold and deeper pits formed as a result of the ablation process. To compare with our modeling prediction (not shown here but presented in Reference 8), we characterized the micropit ensemble morphologies using laser confocal scanning profilometry and propagated a 351-nm laser beam through them, finding good agreement between theory and experiment. Interestingly, as indicated by slope (A) in (b), the highest fluence (~11 J/cm2) showed a second scattering component to the micropit ensemble [slope (B)], which was found to correlate with the onset of fracture-type damage caused by particle-induced Hertzian fractures.2 Thus, through analysis of the far-field scattering angular distribution, pitting/damage types could be deduced without direct imaging of the surface, a fact that might be exploited in damage-monitoring schemes for systems engineering purposes in the future.15,16

Finally, contamination-related optical damage and system performance degradation was found to not only be limited to transmissive optics, but dielectric high reflective optics as well.4,5 Early studies on the effect of particulate contamination showed that the laser-induced damage to the reflective surface is strongly dependent on the contaminant type, size and laser fluences.17 Furthermore, similar to transparent optical components, when these contaminant particles interact with a laser beam, they can create pits and damage sites which can lead to beam modulation, resulting in further damage on optical components downstream.

The representative metallic contaminants used to study multilayer dielectrics were spherically shaped titanium particles, which can be generated in high-power pulsed-laser systems through laser ablation within beam dumps and subsequent deposition of condensed metal vapor on nearby optics. Silica–hafnia multilayer coating samples with different cap layer and high reflectivity (>99.5%) fabricated by e-beam physical vapor deposition were primarily used in our study. Contaminated surfaces were exposed to a ~10-ns, 10 J/cm2 pulse of laser light (p-polarized, 1053 nm) at an incidence angle of 45°.

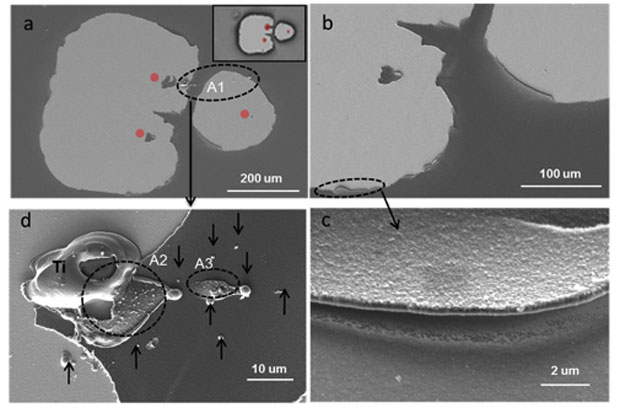

Figure 5(a) shows a representative of modified areas on a titanium-particle-contaminated multilayer dielectric surface following a laser pulse containing three adjacent damaged sites, two of which overlapped each other. At the circumference of each site, the edges are rough and show clear breakage from the host material [(b)]. Higher resolution images of the edges confirm that they are in fact only one-layer thick [(c), for example], which indicates that the interaction between the laser and the titanium particle on the coating surface leads to surface modification by delaminating the capping layer. Moreover, within nearly all the damage sites, a pocket or island of aluminum oxide capping material remains that is not damaged [next to the red dots in (a)]. Interestingly, this undamaged pocket is always close to where the titanium particle resides prior to exposure. This observation suggests that there is a low-energy spot behind the particle where its existence also provides a protecting shadow for the capping layer that is sitting behind.

The salient results of the multilayer dielectric study were that the shape of the particle and the mechanical properties largely dictated the survivability of the multilayer dielectric film after the last pulse. Spherical particles were chosen to closely resemble droplets that might form if titanium metal within a beam dump is vaporized from a laser pulse and subsequently condenses. Interestingly, the smooth spherical surface forms a local reflector, sending the 45° light back to the surface, intensifying the local fluence, and leading to lower damage thresholds for both over-coat materials studied (aluminum oxide and silica).4 In contrast, irregularly shaped titanium particles, such as those that might be formed from mechanical abrasion, tended to yield higher damage thresholds. While the higher fracture toughness and strength of aluminum oxide relative to silica was expected to provide more resilient surfaces with respect to particle-induced damage, the larger thermal expansion actually led to a higher propensity for damage through delamination.

Impact on Mission

Our work has aimed to enable or enhance the performance of several high-power laser systems used for stockpile stewardship and other critical missions throughout the Lab. The primary focus of our study has been mirrors and windows in diode-pumped alkali laser and NIF laser systems. Extending our understanding of contamination effects on light propagation is also related to cyber, space and Intelligence systems that rely on large, high-performance optics. In addition, research related to thermal transport in laser-heated metal microparticles (e.g., aluminum and stainless steel) on surfaces has potential to make an impact on laser-based additive manufacturing technologies being explored for stockpile stewardship and national-security missions.Conclusion

Particle ablation on exit- and input-surface fused-silica windows in high-power laser systems was shown to depend strongly on particle optical properties and orientation. Pump-probe experiment and finite-difference time-domain simulations of metal and glass particle ejection from fused-silica surfaces was used to understand energy-coupling mechanisms that can be used to guide mitigation strategies. Simulated light scattering and intensification associated with particles and pitted surfaces were validated with experiment and used to develop a quantitative tool for system design purposes. An over-coat design was developed in an attempt to reduce particle-induced damage on multilayer dielectric mirror coatings. Experiments related to multilayer-dielectric mirror-coating damage from debris revealed both polarization- and particle morphology-dependent behavior. The results have generated significant interest from industry, in particular related to directed energy and other high-power (e.g., the Laser Interferometer Gravitational-Wave Observatory) laser applications.

References

- Raman, R. N., et al., "Damage on fused silica by laser-ablated surface-bound micro-particles." Optic. Express 24(3), 2634 (2016). LLNL-JRNL-679659.

- Feigenbaum, E., et al., "Laser-induced Hertzian fractures in silica initiated by metal micro-particles on the exit surface." Optic. Express 24(10), 10527 (2016). LLNL-JRNL-686277. http://dx.doi.org/10.1364/OE.23.010589

- Demos, S. G., et al., "Mechanisms governing the interaction of metallic particles with nanosecond laser pulses." Optic. Express 24(7), 7792 (2016). LLNL-JRNL-680178 http://dx.doi.org/10.1364/OE.24.007792

- Qiu, S. R., et al., "Shape dependence of laser–particle interaction-induced damage on the protective capping layer of 1ω high reflector mirror coatings." Optic. Engr. 56(1), 011108 (2016). LLNL-JRNL-673678. http://dx.doi.org/10.1117/1.OE.56.1.011108

- Qiu, S. R., et al., "Impact of laser-contaminant interaction on the performance of the protective capping layer of 1ω high-reflection mirror coatings." Appl. Optic. 54(29), 8607 (2015). https://doi.org/10.1364/AO.54.008607

- Harris, C. L., et al., "Characterization of laser-induced plasmas associated with energetic laser cleaning of metal particles on fused silica surfaces." Optic. Lett. 40(22), 5212 (2015). LLNL-JRNL-6786622.

- Feigenbaum, E., et al., Light scattering from laser-induced shallow pits on silica exit surfaces. Proc. SPIE 9632 (2015). LLNL-PROC-680222. http://dx.doi.org/10.1117/12.2195504

- Feigenbaum, E., N. Nielsen, and M. J. Matthews, "Measurement of optical scattered power from laser-induced shallow pits on silica." Appl. Optic. 54, 8554 (2015). LLNL-JRNL-673988. http://dx.doi.org/10.1364/AO.54.008554

- Feigenbaum, E., S. Elhadj, and M. J. Matthews, "Light scattering from laser-induced pit ensembles on high power laser optics." Optic. Express 23, 10589 (2015). LLNL-JRNL-668127. http://dx.doi.org/10.1364/OE.23.010589

- Matthews, M. J., et al. Phase modulation in high power optical systems caused by pulsed laser-driven particle ablation events. Proc. SPIE 8885, 88850T (2013). LLNL-PROC-646621. http://dx.doi.org/10.1117/12.2030507

- Matthews, M. J., et al., "Phase modulation and morphological evolution associated with surface-bound particle ablation." J. Opt. Soc. Am. B 30(12), 3233 (2013). https://doi.org/10.1364/JOSAB.30.003233

- Matthews, M. J., et al., "Micro-shaping, polishing, and damage repair of fused silica surfaces using focused infrared laser beams." Adv. Eng. Mater. 17, 247 (2015). LLNL-JRNL-654070. http://dx.doi.org/10.1002/adem.201400349

- Matthews, M. J., "Simulating laser-material interactions." Laser Focus World 51(8), 33 (2015). LLNL-JRNL-654070.

- Demos, S. G., et al., Morphology of ejected debris from laser super-heated fused silica following exit surface laser-induced damage. Proc. SPIE 9632, 96320S-96320S-96327 (2015). LLNL-PROC-678399.

- Manes, K. R., et al., "Damage mechanisms avoided or managed for NIF large optics." Fusion Sci. Technol. 69, 146 (2016). LLNL-JRNL-659336.

- Spaeth, M. L., et al., "Optics recycle loop strategy for NIF operations above UV laser-induced damage threshold." Fusion Sci. Technol. 69, 265 (2016). LLNL-JRNL-658260.

- Norton, M. A., et al., Impact of contaminates on the laser damage threshold of 1ω HR coatings. Proc. SPIE 5991, 59910O-59910O (2005). LLNL-PROC-216738.

Publications and Presentations

- Demos, S. G., et al., "Mechanisms governing the interaction of metallic particles with nanosecond laser pulses." Optic. Express 24(7), 7792 (2016). LLNL-JRNL-680178 http://dx.doi.org/10.1364/OE.24.007792

- Elhadj, S., M. J. Matthews, and S. T. Yang, “Combined infrared thermal imaging and laser heating for the study of materials thermophysical and processing properties at high temperatures.” Crit. Rev. Solid State Mater. Sci. 9(3), 175 (2014). LLNL-JRNL-584155. http://dx.doi.org/10.1080/10408436.2013.789962

- Feigenbaum, E., S. Elhadj, and M. J. Matthews, "Light scattering from laser-induced pit ensembles on high power laser optics." Optic. Express 23, 10589 (2015). LLNL-JRNL-668127. http://dx.doi.org/10.1364/OE.23.010589

- Feigenbaum, E., N. Nielson, and M. J. Matthews, "Measurement of optical scattered power from laser-induced shallow pits on silica." Appl. Optic. 54, 8554 (2015). LLNL-JRNL-673988. http://dx.doi.org/10.1364/AO.54.008554

- Feigenbaum, E., et al., "Laser-induced Hertzian fractures in silica initiated by metal micro-particles on the exit surface." Optic. Express 24(10), 10527 (2016). LLNL-JRNL-686277. http://dx.doi.org/10.1364/OE.24.010527

- Feigenbaum, E., et al., Light scattering from laser-induced shallow pits on silica exit surfaces. Proc. SPIE 9632 (2015). LLNL-PROC-680222. http://dx.doi.org/10.1117/12.2195504

- Guss, G.M., et al., "Nanoscale surface tracking of laser material processing using phase shifting diffraction interferometry." Optic. Express 22(12), 14493 (2014). LLNL-JRNL-651800. http://dx.doi.org/10.1364/OE.22.014493

- Manes, K. R., et al., "Damage mechanisms avoided or managed for NIF large optics." Fusion Sci. Technol. 69, 146 (2016). LLNL-JRNL-659336.

- Matthews, M. J., et al., Laser–matter coupling mechanisms under varying chemical and particulate surface configurations. (2016). LLNL-PRES-642644.

- Matthews, M. J., “Simulating laser–material interactions.” COMSOL News. (2015). LLNL-JRNL-676176. https://www.comsol.com/story/simulating-laser-material-interactions-44661

- Matthews, M. J., "Simulating laser–material interactions." Laser Focus World 51(8), 33 (2015). LLNL-JRNL-654070.

- Matthews, M. J., et al., "Characterization of laser-induced plasmas associated with energetic laser cleaning of metal particles on fused silica surfaces." Optic. Lett. 40, 5212 (2015). LLNL-JRNL-678662. http://dx.doi.org/10.1364/OL.40.005212

- Matthews, M. J., et al., "Micro-shaping, polishing, and damage repair of fused silica surfaces using focused infrared laser beams." Adv. Eng. Mater. 17, 247 (2015). LLNL-JRNL-654070. http://dx.doi.org/10.1002/adem.201400349

- Matthews, M. J., et al., “Phase modulation and morphological evolution associated with surface-bound particle ablation.” J. Opt. Soc. Am. B 30(12), 3233 (2016). LLNL-JRNL-642363. https://doi.org/10.1364/JOSAB.30.003233

- Matthews, M. J., et al., Phase modulation in high power optical systems caused by pulsed laser-driven particle ablation events. SPIE Laser Damage 2013, Boulder, CO, Sept. 22–25, 2013. LLNL-ABS-635212.

- Negres, R. A., et al., "Growth model for laser-induced damage on the exit surface of fused silica under UV, ns laser irradiation." Optic. Express 22(4), 3824 (2014). LLNL-JRNL-646600. http://dx.doi.org/10.1364/OE.22.003824

- Qiu, S. R., et al., "Impact of laser–contaminant interaction on the performance of the protective capping layer of 1 omega high-reflection mirror coatings." Appl. Optics. 54, 8607 (2015). LLNL-JRNL-673678. http://dx.doi.org/10.1364/AO.54.008607

- Qiu, S. R., et al., Impact of particle shape on the laser-contaminant interaction induced damage on the protective capping layer of 1 omega high reflector mirror coatings. Proc. SPIE, 9632 (2015). LLNL-CONF-680222. http://dx.doi.org/10.1117/12.2195517

- Raman, R. N., et al., "Damage on fused silica optics caused by laser ablation of surface-bound microparticles." Optic. Express 24(3), 2634 (2016). LLNL-JRNL-679659. http://dx.doi.org/10.1364/OE.24.002634

- Raman, R. N., et al., “The role of electronic defects and brittle microstructure in laser-driven material failure.” J. Phys. Appl. Phys. 47(34), 345304 (2016). LLNL-JRNL-647302. https://doi.org/10.1088/0022-3727/47/34/345304

- Shen, N., et al., Energetic laser cleaning of metallic particles and surface damage on silica optics: Investigation of the underlying mechanisms. Proc. SPIE. 9632 (2015). LLNL-CONF-679001. http://dx.doi.org/10.1117/12.2195593

- Spaeth, M. L., et al., "Optics recycle loop strategy for NIF operations above UV laser-induced damage threshold." Fusion Sci. Technol. 69, 265 (2016). LLNL-JRNL-658260.

![14erd098_Fig3_620.jpg Figure 3. (a) plasma temperature as a function of gate delay for a 316l steel particle on silica substrate irradiated with single, 1064-nm, ~10 gw/cm<sup>2</sup> laser pulse. the inset shows a typical plasma spectrum used to derive plasma temperature from iron [fe(i)] and silica substrate [si(ii)]. (b) comparison of temperatures as a function of laser intensity extracted from plasma emission lines related to the fused silica substrate [si(ii)] and the ejected stainless steel particle [fe(i)].](https://ldrd-annual.llnl.gov/sites/ldrd_annual/files/2020-10/14erd098_Fig3_620.jpg)