Alexander Gash | 16-ERD-040

Overview

In this project, we investigated the application of three-dimensional material printing (3DP) to energetic materials (e.g., explosives and pyrotechnics). The initiation and energy release properties of these materials can be highly dependent on the materials' micron-scaled structure and composition. Conventional energetic materials processing provides no engineering control of material architecture on this length scale. Selected 3DP techniques do provide engineering control at the scale of 10s–100s of microns, which enables a new parameter to the control of performance and safety characteristics. In this effort, we developed custom 3D-printable energetic feedstocks and used 3DP techniques to fabricate energetic materials with material architectures that were engineered to have spatially modulated density, structure, and or composition. This approach allowed the systematic investigation of the influence of these characteristics on the initiation and energy release properties of both pyrotechnics and explosives. This development enabled the correlation of select material architectures of a pyrotechnic for energy release rate and linear combustion velocity, as well as substantial control of those properties. For the field of high explosives (HE), this study demonstrated that discreetly placed localized aluminum powder can augment the pressure profile and detonation reaction to lengthen and shift the secondary pressure peak observed in aluminized explosives. Finally, this study showed that topology optimization and engineering of the material composition of the interface between two explosives using 3DP methods is a new and viable tool for engineering the performance of energetics.

Background and Research Objectives

The bottom-up additive fabrication of energetic materials with arbitrary three-dimensional meso-structures and with internal micron-scaled architectures is an excellent platform on which to perform science that will provide a strong fundamental basis for enabling applications. With 3DP techniques and custom energetic formulations, experimenters have the ability to design and control microstructural features of high explosives that are on a length scale commensurate with the critical processes that dictate dynamic behavior: conduction, convection, advection (in pyrotechnics), hot spot coalescence, shock-to-detonation transition, and detonation wave propagation (in explosives).

While previous breakthroughs in energetic materials science and applications have centered on the discovery of an outlier material, one with exceptional safety or performance characteristics, through this project, we sought instead to discover outlier architectures, which is to say, the precision placement and arrangement of materials and/or voids relative to one another in three-dimensions that enables an enhanced or novel property. Our goal was to understand and quantify the link between the relative placement of materials and defects and the resultant dynamic response. Specifically, we had the following objectives:

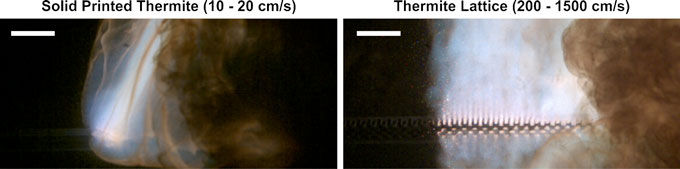

- To understand the relationship between 3D structure and the energy release of thermites (see figure).

- To use 3D structure to control the blast characteristics of metalized explosives.

- To use topology optimization to design an acceptor-donor HE system with tailored performance.

The process that resulted from this project represents a new design paradigm in energetic materials science and technology, one in which the HE microstructure is designed specifically for the application requirements.

Comparison of printed thermite reaction modes. At left, "fully dense" thermite (printed with no engineered porosity) propagates slowly and exhibits a relatively narrow flame front. At right, thermite lattices propagate up to two orders of magnitude faster and show a much broader flame zone led by a front of hot gasses and particles. The scale is the same in both images (scale bar =1 cm).

Impact on Mission

This effort supported Lawrence Livermore National Laboratory's research and development priorities in stockpile stewardship science and enhanced the Laboratory's advanced manufacturing capabilities. Specifically, we created new feedstocks using energetic materials, used 3DP techniques to build explosive structures, and provided computational strategies for energetic assembly design. These methods enable a more detailed understanding of new energetic material architectures, which will support a more innovative design process for components, leading to improvements in the performance, safety, and precision of both the nuclear and conventional stockpiles. This effort has pioneered a new direction in HE engineering while expanding the Laboratory's competencies in high-performance computing and materials behavior under extreme conditions. The resulting transformational developments in HE science and design have led to high-impact publications and important intellectual property for the Laboratory (see below). This effort has contributed to the maintenance of Lawrence Livermore's position as the center for excellence in HE research and development within the NNSA and has provided an important platform on which to perform innovative science and technology.

Publications and Presentations

- Bukovsky, E. 2017. "Experimental Study of Structure/Behavior Relationship for a Metallized Explosive." APS 20 th Biennial Conference on Shock Compression of Condensed Matter, St. Louis, MO, July 9–14, 2017. LLNL-PROC-738332.

- Gambino, J. R., et al. 2017. "Numerical Study of Donor–Acceptor Interface Designs in a Double Cylinder Experiment." JANNAF meeting, Kansas City, MO, 22-25 May, 2017. LLNL-CONF-729692.

- Gash, A.E., et al. 2018. "Architected Materials and Structures to Control Shock Output Characteristics," U.S. Patent 10,036,616 B2. July 2018.

- Reynolds, J.G., et al. 2018. "Explosives Mimic for Testing, Training, and Monitoring," U.S. Patent 9,890,092 B1. February 2018.

- Reynolds, J.G., et al. 2018. "K-9 Training Aids Using Additive Manufacturing," U.S. Patent 9,887,419 B1. February 2018.

- Springer, K. et al. "Numerical Study on Tailoring the Shock Sensitivity of TATB-Based Explosives Using Mesostructural Features." APS 20 th Biennial Conference on Shock Compression of Condensed Matter, St. Louis, MO, July 9–14, 2017. LLNL-ABS-724986.