Robert Panas (16-ERD-006)

Executive Summary

We aim to improve the precision of computerized-tomography (CT) metrology in the micrometer to nanometer range, providing better information and machine models to determine trade-offs between speed, spatial resolution, and signal-to-noise ratios. These improvements can help control the geometry, surface finish, and densities of polymer parts during the additive manufacturing (AM) process.

Project Description

Additive manufacturing processes have great potential to engineer materials by enabling the precise localized control of geometry and properties over a large volume. However, these processes have failed to deliver on this potential because of uncontrolled process variations. For example, additively manufactured parts currently fabricated at Lawrence Livermore National Laboratory frequently fail tolerance requirements for geometry, surface finish, and material quality because of process uncertainty. The ability to accurately measure process variations is critical to reducing this uncertainty so that AM processes can be integrated into fabrication for field-specific applications.

The unique challenges posed by additively manufactured parts—internal features, spatially varying properties, and irregular shapes—negate the use of existing precision metrology techniques. Computerized tomography produces three-dimensional images of an object by x-ray imaging from several different angles and computationally combining these images. It is a viable alternative to existing techniques. However, commercially available CT systems are often optimized for nondestructive testing or medical imaging, fields in which qualitative measurements are generally sufficient to successfully diagnose anomalies. Such data have limited value for accurately quantifying variations in additively manufactured parts. We will develop precision CT metrology specifically for additively manufactured parts to measure characteristics such as part geometry, surface finish, and density. To accomplish this goal, we plan to explore the science and physics of a CT machine to generate an understanding that lets users make informed performance trade-offs between speed and resolution.

Additive manufacturing is a rapidly evolving field whose general trend is moving from demonstrating new processes to fine-tuning them. As it matures, end users place increasing demand on the fabrication process to generate parts within strict tolerances defined by real-world usage conditions, including the need to meet geometry, surface finish, and material quality requirements. Our project will meet the growing demand of adding precision to AM by developing a CT capability that can obtain information at the nanometer scale. As a result, we expect to improve the Laboratory's precision CT metrology capability in the range of 65 µm to 200 nm, providing users with more and better information about the resultant parts, as well as machine models so that they can make trade-offs between speed, spatial resolution, and signal-to-noise ratios. This improved capability will be used to understand and control the additive manufacturing of polymer parts, allowing users to deterministically fabricate such parts with geometry, surface finish, and densities that are within design tolerances, and allow the further development of additive manufacturing of metal parts on other AM systems, such as metal powder-bed machines.

Our efforts to improve computerized tomography consist of a combined multi-group machine design, metrology, and modeling effort. We will feed information gathered through continuous tomographic scanning of parts back into the modeling effort to better control the process, provide predictability, and ultimately improve the manufacturing process.

Mission Relevance

This project supports the Laboratory’s core competency of advanced materials and manufacturing by advancing development of rapid, cost-effective manufacturing processes of polymer, and ultimately metal systems, using AM. Such efforts will also advance the nondestructive evaluation of additive manufactured parts such as targets for the Laboratory’s National Ignition Facility, in support of the core competency of nuclear weapons science and DOE goal in nuclear security to maintain the safety, security, and effectiveness of the nation’s nuclear deterrent without nuclear testing.

FY17 Accomplishments and Results

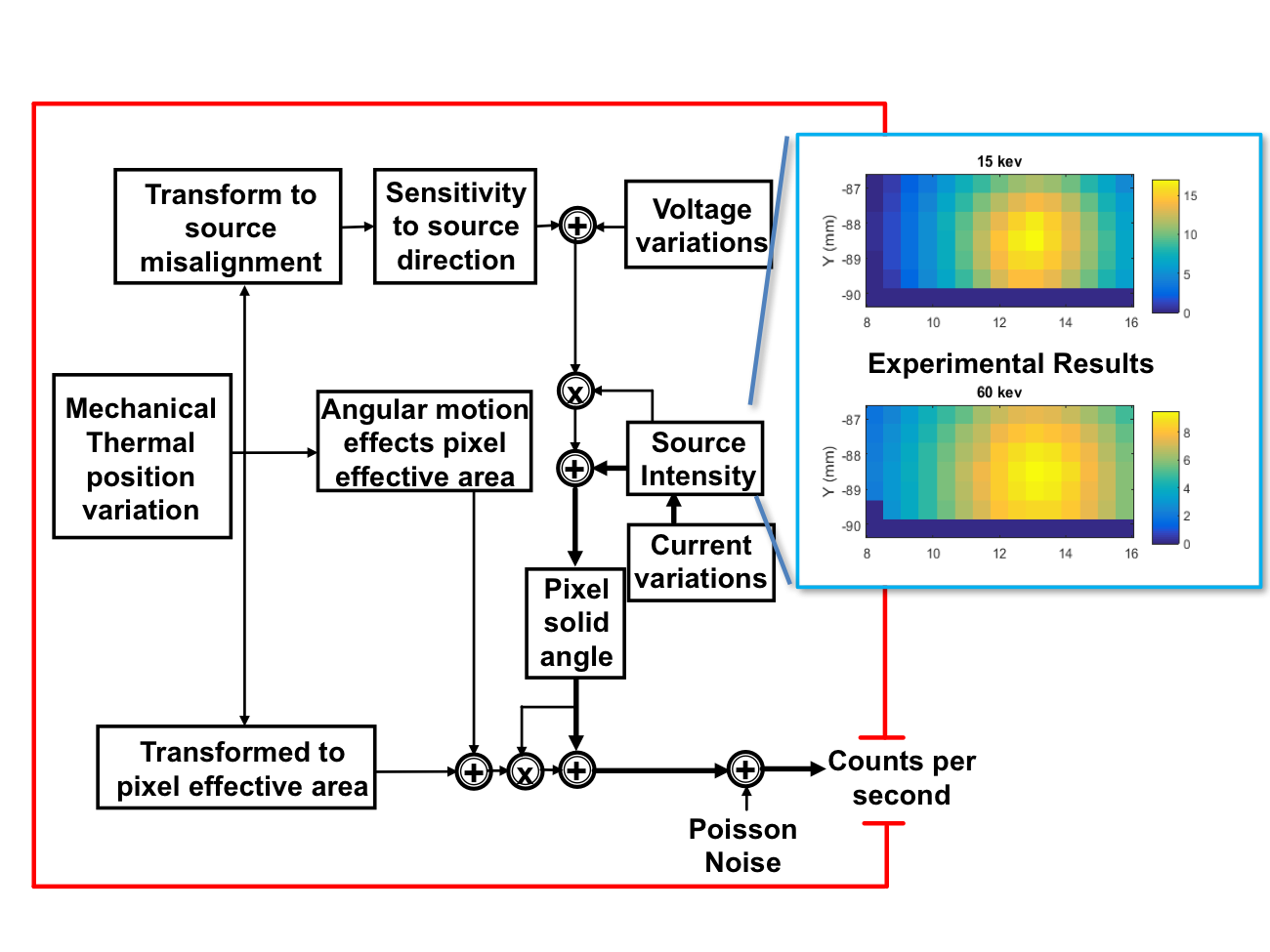

In FY17 we (1) created the planned uncertainty models (called signal variation flow graphs) for computerized tomography, and used the first and most difficult model for an algorithm; (2) performed experiments on selected CT systems to extract the machine-specific parameters that our models require, which will help us determine a standard set of CT performance tests that can be run on any machine to rapidly and fully capture its internal states; (3) determined that such information, when fed into our algorithm, provides us with the capability to improve data capture, teach us how to improve machine hardware, and predict uncertainty in measurement, which is a necessity for using CT systems as rigorous metrology in developing future AM processes; (4) developed physics models to understand the capabilities of the Nanoscribe two-photon polymer stereolithography additive-manufacturing printer so that we can print parts to use as CT artifacts; (5) extended our study of the Nanoscribe printer to detailed machine characterization so that we could learn what the machine could and could not do; (6) developed inks that can be observed with CT, with which we can create nanoscale features; and (7) began creating CT test artifacts that can be used to explore the limits of a CT system.

We have developed models and techniques to expand and improve the data we can capture when using CT imaging of additively manufactured parts. This includes new techniques to create micro- and nano-structured artifacts that can be used to explore the limits of CT metrology capabilities. In parallel with our new testing artifacts, we have created an analytical tool to understand uncertainty propagation in the CT machine. The uncertainty model helps us understand how variations from multiple domains (electronic, thermal, mechanical, and emission) propagate through the system to create errors in measurement. This is the first such uncertainty model to capture the entire physical domain including 2D images (radiographs); it was previously thought to be unfeasible. Such understanding allows us to quantitatively predict uncertainty for CT measurements, a critical requirement for the metrology of manufactured parts. It also allows us to identify methods to improve the machine and its performance by studying the relative effect of the sources of uncertainty.

Publications and Presentations

Cuadra, J.A., et al. 2017. "Uncertainty Quantification of an X-ray System Via a 2D Model Using a System Approach." 31st ASPE Annual Meeting. LLNL-ABS-702326.

Saha, S., et al. 2017. "Process and Equipment Driven Limits to the Performance of Two-Photon Polymerization Based Submicron Additive Manufacturing." 31st ASPE Annual Meeting. LLNL-ABS-687320.