Roger Aines (13-ERD-029)

Abstract

Water use in hydraulic fracturing for natural gas production is strongly affected by the need to drive fracture materials known as proppants, which are typically rounded sand grains, into the created fracture to hold it open during gas production. This requires the water to be viscous to move the dense sand particles. The complex mixture of thickeners and friction reducers makes it difficult to treat and reuse the water. If a proppant could be created that has a similar density as the water used to place it, the produced fluid would be much easier to treat. We addressed this need by creating neutral-density proppants composed of a reactive material encapsulated in a silicone shell, which reacts within the fracture to become very strong and expansive. These synthetic materials proved extremely valuable in tracking experimental propping of fractures, and in validating models of proppant movement in fractures. The models we created have improved both the efficiency and reduced the environmental impact of natural gas production and provide the only full-physics description of proppant flow in fractures.

Background and Research Objectives

The water used in hydraulic fracturing for natural gas exploration and extraction must be viscous to move the dense sand particles, which results in a complex mixture of thickeners and friction reducers that makes it difficult to treat and reuse the water. If these agents were unnecessary, the fluid would be much easier to treat. However, removal of these thickeners would require that the proppant have a density similar to the water used to place it. We proposed to address this need by creating a temperature-set proppant, a reactive material encapsulated in a silicone shell, that is malleable and of neutral density, ensures deep placement, and then sets to solid with good permeability after the proppant hardens. Our research goals for this development of reactive materials for use in hydraulic fracturing were (1) create a mineral filling for the proppant capsules used in fractures for gas production that sets and slowly expands upon curing; (2) complete a detailed proppant transport model, test it using x-ray facilities at the National Energy Technology Laboratory in West Virginia, and examine the effect of asperities and changes in fracture aperture on transport; (3) optimize the proppant design to maximize transport and strength with good permeability after the proppant hardens; and (4) demonstrate scale-up of production to enable large-scale use of these materials.

Scientific Approach and Accomplishments

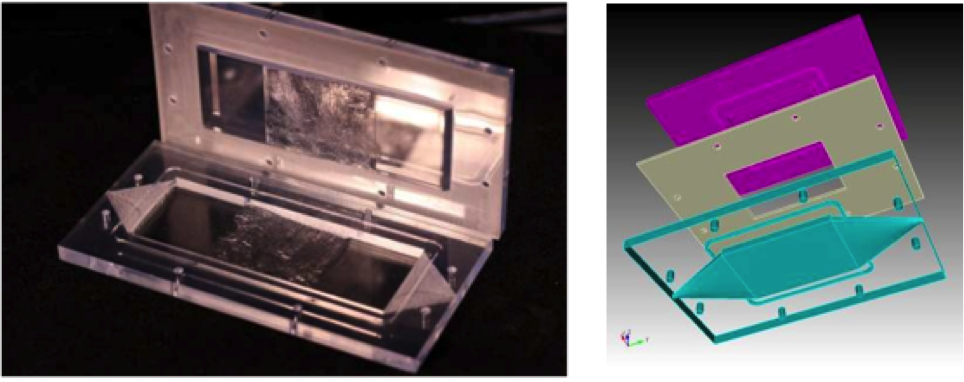

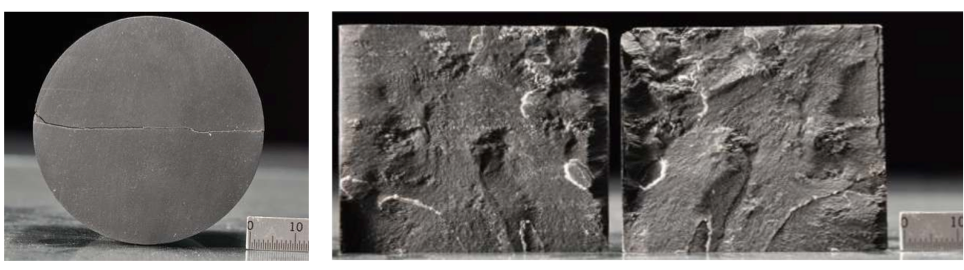

While the transport behavior of proppant in natural fracture geometries can be studied in core flood experiments, data gained from such experiments provides only a picture of the integrated response of the fracture. The response of individual proppant particles, and more importantly their modal behavior, is lost. Although x-ray tomography can be used to study in situ proppant physics, processes occurring on timescales pertinent to particle transport cannot be captured with the present state of the technology. Instead, we reproduced the effects of the natural fracture geometry by using three-dimensional printing to reproduce the fracture in a clear plastic resin (Figure 1). The transparent flow cells allow the particle motion to be viewed directly without the need for specialized imaging equipment. A sample of Marcellus shale provided by the National Energy Technology Laboratory was fractured and scanned to provide the fracture surfaces for the flow cell used in this study. The initially competent sample was bisected by a single natural fracture that was formed at depth and later cemented with calcium carbonate. After coring, the sealed fracture was reopened using a Brazilian test apparatus, and the resulting surface characterized with a combination of x-ray computed micro-tomography and laser profilometry. The micro-tomography scan confirmed that the reopened fracture followed the path of the previous cemented fracture and verified that no artifacts or errors were introduced during the profilometry scan. Regions where the two fractured half-cores deviated from the natural fracture (e.g., towards the edges of the sample where a slight breakout occurred from the Brazilian test) were excluded from the surface reproduced in the flow cell.

While laser profilometry provides extremely high-resolution data on the surface topology, the two fracture surfaces must be separated for imaging. This introduces slight errors in the alignment of the two surface scans. Recovering the correct alignment of the fracture surfaces is important, because even minor variations in the relative orientation can influence the flow characteristics. Accordingly, digital image correlation was used to realign the two fracture surfaces in three dimensions. The aligned surfaces were used for both the experimental study and the numerical simulations.

Stereolithographic techniques were used to print the flow cell, incorporating surfaces of the fractured shale sample at a resolution of 50 μm per layer in clear SOMOS Water-Shed XC 11122 plastic resin. The flow cell consists of two pieces: the roof of the cell containing one-half of the fracture surface, and the floor containing the opposite surface along with the entry and exit ports (Figure 2). The cell was designed such that the fracture surfaces would come into contact when the two pieces were mated, effectively sealing the cell. This allowed the fracture aperture to be set by introducing a spacer of known thickness between the two cell pieces. Bolt holes and a silicon gasket were also included in the flow-cell design. Some minor machining was required post-printing to add Luer locks to the flow cell. The completed flow cell was connected to a syringe injector pump and mounted on an adjustable stage. A high-speed camera was also fitted to the stage, allowing the orientation of the fracture to be arbitrarily adjusted without affecting the relative position of the camera.

Commercial-grade proppant was employed in early testing with the flow cell. However, this proved impractical for particle tracking because the paths of individual particles were lost within the particle pack. While particle image velocimetry techniques were initially used to track the bulk motion of the pack with some success, this proved less useful for studying inclined fractures where the proppant would often be separated into a stationary pack occupying the bottom of the fracture, with a smaller group of entrained particles flowing over the top.

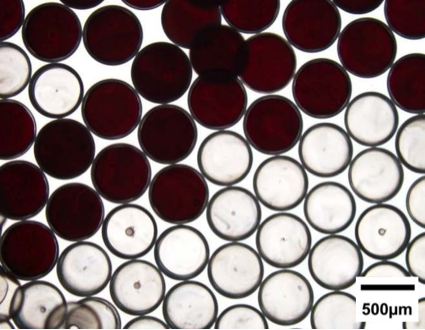

To improve particle tracking in the experiments, we fabricated a synthetic proppant analogue that consisted of a mixture of transparent and opaque microcapsules (Figure 3). The hard microcapsules were created from double emulsions formed in a capillary flow-focusing micro-fluidic device. The device combines the flows of three immiscible fluids (aqueous, silicone, and aqueous phases), thereby forming nested, metastable droplets of the fluids—that is, a double emulsion. The resulting capsules have very monodisperse (>95%) dimensions in both shell wall and exterior diameter metrics. For this study, the outer droplet phase consisted of a photo-polymerized-enabled adhesive (NOA 61, Norland Products) that hardens when exposed to ultraviolet light. Once formed, the liquid double emulsions were collected and cured in small batches under ultraviolet illumination to produce hard proppant particles. The opaque capsules were created by adding a black dye to the interior aqueous phase during the encapsulation process, an approach that resulted in the creation of two groups of visually distinct proppant particles with virtually identical hydrodynamic characteristics. This was particularly important for the experimental study. It was found that even slight differences in the size or density of the particles could result in the segregation of the two particle populations, nullifying the effectiveness of the tracer particles. The density of the micro-capsules used for the settling experiments was 1.1 g/cm3, although variable density micro-capsules tailored for specific applications can be created by altering the interior fluid or injecting glass micro-bubbles inside the capsules.

Figure 3. Examples of hydrodynamically identical, transparent bulk and opaque tracer particles created using microscopic encapsulation.

The simulations were performed with the LMC–SAMRAI hybrid code (low mach code and structured adaptive mesh refinement application infrastructure). LMC is a massively parallel computer code developed for direct numerical simulation of particulate flow. The code is based on a distributed Lagrange multiplier technique in which both the interstitial fluid and particles are fully resolved and coupled. Particle–particle interaction is represented with frictional, inelastic contact forces similar to those used in discrete-element models. Moreover, the code is able to handle arbitrary particle shapes and size distributions. Its parallel implementation, based on LLNL's SAMRAI framework, allows the handling of a large number of rigid particles and has been demonstrated to scale efficiently to thousands of processors.

The fracture geometry for the base case used in the numerical simulations matched the fracture surfaces used in the experimental flow cell. The two halves of the fracture were displaced by 1-mm normal to the fracture plane. For simplicity, no additional tangential or rotational motions were imposed on the fracture surfaces. This is a reasonable preliminary assumption for hydraulic fractures, which will open normal to the direction of minimum principle compressive stress, and matches the displacements imposed in the experimental study. However, this leads to a uniform aperture distribution across the fracture, whereas shear between the two fracture surfaces would result in more channelized flow. While this would not appear to affect the base case significantly, this may have more of an effect in rough fractures as discussed below.

The simulated particles had the same diameter (500 μm) as the micro-capsules used in the experiment, but a higher density (2.5 g/cm3), closer to that of real proppant. The higher density had the benefit of increasing settling speeds in the simulations, which reduced the amount of simulation time. Conversely, the reduced settling speeds in the experiments facilitated particle tracking.

Although proppant has been used to improve fracture permeability in many thousands of stimulations, our understanding of proppant transport remains relatively rudimentary. The development of novel proppant deployment strategies and new types of proppant will require new techniques for predicting proppant behavior that include such features as the ability to track particle dispersion and accurately represent the slip between the proppant and its carrier fluid. Moreover, while many current numerical models of proppant transport rely on empirical closure relationships based on slurry-flow models to complete the governing equations, such models assume that the particle dimensions are far smaller than those of the flow geometry as a whole. As a consequence, these models may underestimate the effect of the fracture geometry on the proppant behavior.

New experimental and numerical methods capable of resolving sub-fracture-scale behavior are needed to better understand the behavior of proppant in fractures and improve these empirical models. We have presented results from studies employing two such methods: high-resolution, high-fidelity sub-fracture-scale particle-flow simulations and particle flow-cell experiments in synthetic reproductions of natural fracture geometries. The results of these studies illustrate the high levels of particle dispersion experienced by the settling proppant pack. The bulk of this dispersive behavior arises from the interaction between the upwelling of the displaced interstitial fluid and the settling particles, rather than the effects of the fracture geometry. This was reflected both in the studies involving vertical fractures and those studies considering fracture orientation, where it was found that frictional particle-wall effects dominate only at high inclination angles. The numerical simulations of proppant settling additionally suggest that the interactions between fluid and particles also influence the distribution of particles across the fracture, forcing the particles to be displaced towards the fracture sides. This behavior differs from the behavior observed in horizontal particle flows, where hydrodynamic forces tend to concentrate the particles towards the center of the fracture, which points to a need to account for the interplay between wall effects and the slip velocity in models of proppant transport and dispersion. This is also true when considering theories of hindered settling, as demonstrated by the experimental results comparing settling rates for different volume fractions.

Impact on Mission

This work addresses a core LLNL strategic focus area in energy and climate with applications to natural gas production and geothermal energy production. Our experiments described here led to an enhanced collaborative relationship with the National Energy Technology Laboratory in West Virginia, the dedicated fossil-energy laboratory that conducted the imaging of proppant placement in their x-ray tomography facilities. Developing proppant materials also aligns well with the Laboratory’s core competency in advanced materials and manufacturing.

Conclusion

We successfully created a new class of proppants with unique properties, including the ability to expand once placed in a fracture. We developed a new laboratory method for observing the flow of proppant in real fractures and used this to help develop high-performance models of proppant flow. These models have attracted the attention of industry because they are the only detailed models of proppant flow that take into account both fracture geometry and individual flow of particles and the effect that those two factors have on the hydrodynamics of the bulk flow. This capability has further established LLNL leadership in the modeling and control of fractures for energy extraction and waste storage.

Publications and Presentations

- Pratanu, R., W. L. Du Frane, and S. D. C. Walsh, Proppant transport at the fracture scale: Simulation and experiment. 49th U.S. Rock Mechanics/Geomechanics Symp., San Francisco, CA, June 28–July 1, 2015. LLNL-CONF-667755.

- Pratanu, R., et al. Fabrication and transport of double emulsion microcapsules for applications in unconventional resources. Unconventional Resources Technology Conf. (URTEC), San Antonio, TX, July 20–22, 2015. LLNL-PROC-668998.