Paul Leisher (17-ERD-069)

Executive Summary

We are exploring a new framework that will enable the design of lasers with improved output power, efficiency, and reduced risk of diode failure. This framework will predict resistance to damage by back-irradiance from reflections for a range of device configurations and operating conditions, and will have applications for defense, scientific exploration, and industry.

Project Description

Our objective is to develop a predictive capability for laser diode impairments and damage caused by back-illumination. This research will enable design of more powerful lasers at lower cost for defense applications, industrial use, and scientific exploration. Our research focuses on laser diodes that are the preferred pump source for high-power laser systems, which is essentially the heartbeat of the laser. Currently, we are limited in how high we can increase laser power because amplification can damage the diode system when exposed to back-irradiance from reflections or laser fluorescence. An overloaded system absorbs too much of the light energy produced and can melt and recrystallize semiconductor material at the facets of the laser. Such catastrophic optical damage can occur in less than a millisecond in a single laser pulse and is one of the limiting factors in increasing laser performance. Our research will develop a model framework to predict resistance to damage by back-irradiance for a range of device configurations and operating conditions using experimental data to quantitatively anchor the model. This new framework will enable the Lawrence Livermore National Laboratory to design future lasers with improved output power and efficiency and reduced risk of diode failure.

While much effort has been devoted to improving device designs and facet coatings to increase damage thresholds, the system advantages of operating diodes at high output power invariably lead laser designers to push these limits. When diodes are driven at aggressive operational levels based on characterization performed in isolation and then subjected to back-irradiance in real systems, impairments can occur, including accelerated degradation rates or catastrophic failure. For this reason, we are developing and experimentally validating a framework for predicting failure thresholds and aging acceleration for a range of diode components and operating conditions. Such a capability would significantly enhance our ability to design diode-pumped lasers and enable us to operate diodes at higher output irradiance without risk of failure. Higher diode irradiance improves output power and efficiency of laser systems and reduces their cost. If successful, our model framework will predict back-irradiance effects on laser diode lifetime. Applications include energy, remote sensing with laser-based instruments, scientific exploration via accelerator end-stations, materials processing, and laser peening to stress-test new materials and assisted deposition.

Mission Relevance

This project directly supports the Laboratory’s core competency in lasers and optical science and technology, as well as the mission research challenge in directed energy by advancing capabilities fundamental to the NNSA mission. Laser diodes are the preferred pump source because of their power and efficiency, but diode reliability is impaired in low back-irradiance levels. Currently, no method exists for predicting those levels. Thus, a better understanding of back-irradiance effects is key for designing diode-pumped lasers. This work will also support the DOE goal of strengthening key science, technology, and engineering capabilities and modernizing the national security infrastructure.

FY17 Accomplishments and Results

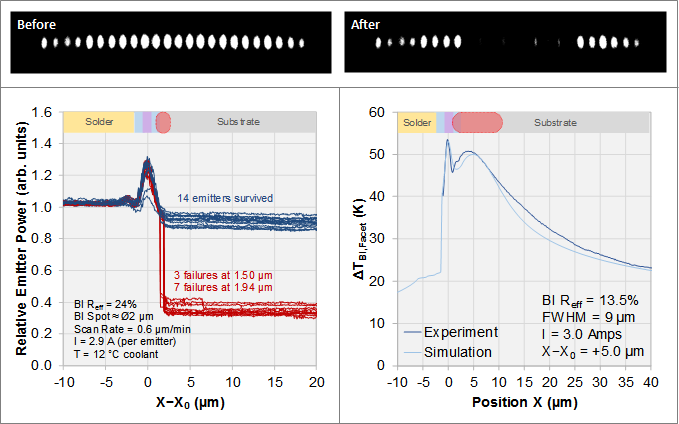

In FY17, we (1) developed a framework to assess back-irradiance-induced failures—the back-irradiance parameters are treated as stressors that accelerate device failures, and statistical analysis of the times-to-failure was used to build a quantitative acceleration model; (2) designed and commissioned the optical setup and test station required to perform destructive experiments, and began initial step-stress testing; (3) secured an outside vendor to perform nondestructive testing of thermal properties using measurements of the relative change in the sample's surface reflectivity as a function of temperature, which will be used in conjunction with thermal simulations to validate and explain the acceleration model; and (4) began initial destructive back-irradiance testing and the development of the preliminary acceleration model.

Publications and Presentations

Boisselle, M. C., et al. Forthcoming. "Reliable Operation of High Power Diode Pumps in Laser Systems with Back-Irradiance." 2018 SPIE Photonics West. LLNL-ABS-736797.

Leisher, P. O., et al. 2017. "Root Cause Investigation of Back-Irradiance-Induced Failure of High Power Diode Lasers." In Session 3: Working in the Real World – Laser Reliability and Performance. Proceedings of 2017 IEEE High Power Diode Lasers and Systems (HPD) Conference, Coventry, U.K., October 11–12. LLNL-PROC-739350.

Li, C., et al. Forthcoming. 2018. "Thermal Imaging of Back-Irradiance in High Power Laser Diodes." SPIE Defense + Commercial Sensing Symposium. LLNL-ABS-739409.