Rebecca Dylla-Spears (16-SI-003)

Executive Summary

Using additive manufacturing methods, we are investigating new classes of functionally graded optical materials with spatially tailored changes in properties. The project will enable fabrication of optimal, robust, lightweight, and compact optics that cannot be achieved by conventional means with applications in high-average-power laser systems for inertial fusion energy, defense, and industry.

Project Description

Optical systems require proper management of thermal, optical, and mechanical properties to function as intended. Design choices must be made based on both the availability of optical components and the needs of the system. Ultimately, the final optical-system design requires a balance between cost, schedule, weight, compactness, and complexity. Optics made from standard bulk materials fabricated by conventional methods often cost less. However, a single bulk material typically does not possess the desired combination of material properties, such as thermal conductivity, density, stiffness, strength, transparency, or absorbance at a desired wavelength. Thus, designs using traditional components made from bulk materials may require the use of extra compensating optics, structures, or thermal-management features that increase the system's complexity, footprint, and weight. In an effort to reduce system weight or improve efficiency, a designer may instead prefer to use optical components made with functionally graded materials that contain spatially varying compositions or microstructures that result in changes in properties. The availability of such materials is limited by current processing techniques. Using additive manufacturing methods, we plan to create a new class of functionally graded optical materials with spatially tailored changes in properties. We expect to fabricate three optical elements that are not achievable by conventional fabrication techniques: (1) a transparent ceramic laser gain medium with a gradient in absorption and gain coefficients via changes in dopant concentration, (2) a silica glass aberration-corrector plate with a gradient in refractive index via compositional change, and (3) a large metal aspherical mirror with a gradient in stiffness via an engineered structural change.

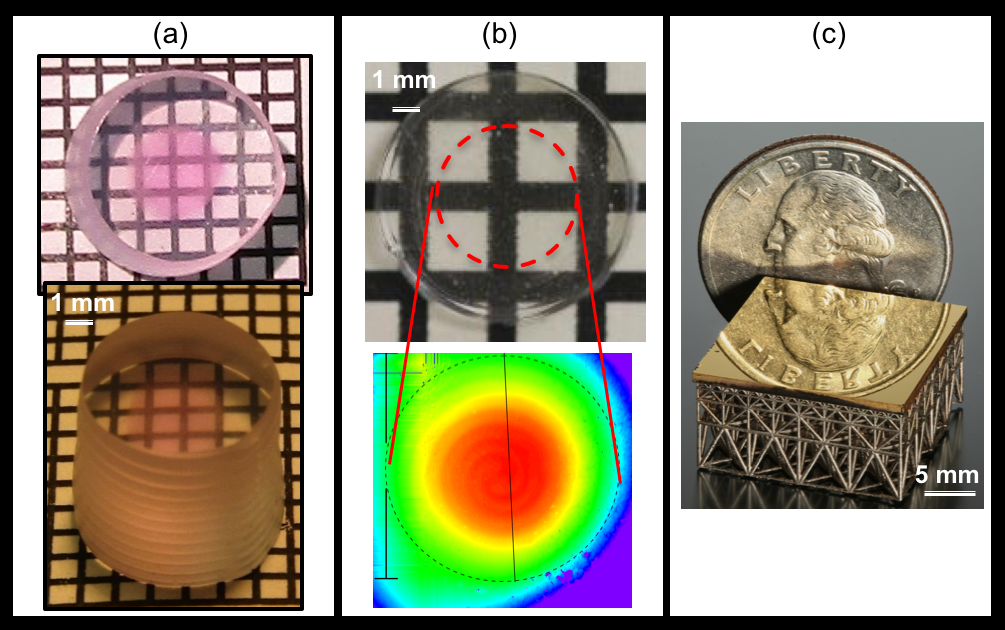

We intend to develop ink formulations and processing techniques needed to produce gradient-composition transparent ceramic and glass optics from additively manufactured green bodies that are weakly bound ceramic forms prior to sintering or heating. A transparent ceramic laser gain medium with a radial gradient in gain coefficient will be printed as a green body using direct ink writing (DIW). Adjustments in the relative flow rates of a doped ink stream and a non-doped ink stream will enable in-line variation of the neodymium doping concentration during printing. After printing, the green body will be sintered to transparency. A silica glass aberration-corrector plate with a non-monotonic radial gradient in refractive index will also be prepared using DIW technology. The refractive index gradient will be introduced during printing using titanium oxide and silicon dioxide inks blended in varying ratios. The printed form will then be consolidated to form the glass via heat treatment. Finally, a large nickel aspherical mirror will be made lightweight by incorporating a gradient in stiffness and density. Projection micro-stereolithography will be used to print a microscopic truss lattice on the back side of the shaped mirror surface. The support-feature scale length will be varied and optimized to provide the greatest stiffness near the mirror surface while minimizing total weight.

We anticipate that this research project will generate intellectual property associated with optical component design, ink development, and optical component fabrication processes, and will establish Lawrence Livermore National Laboratory as a leader in additively manufactured optical materials and components.

Mission Relevance

The ability to create new, functionally graded optical materials by additive manufacturing has the potential to transform optical system design. It will enable the fabrication of optimal, robust, lightweight, and compact optics that cannot be achieved by conventional means and is therefore well aligned with the Laboratory's core competencies in lasers and optical science and technology and also advanced materials and manufacturing. Our research is expected to advance the Laboratory's interests in space and intelligence applications, as well as in compact, high-average-power laser systems for inertial fusion energy, defense, and industrial applications. These endeavors support DOE goals and objectives in science and energy by delivering scientific discoveries and major scientific tools that help transform our understanding of nature. Technologies developed here are also expected to be of interest to the broader optics, materials science, and advanced manufacturing communities.

FY17 Accomplishments and Results

In FY17, we (1) installed a new DIW printer; (2) fabricated the first silica–titania composite gradient-index lens (9 mm diameter and 2 mm thick with a parabolic radial index change of 0.005) using a DIW printer; (3) developed a model to improve compositional control during printing and developed tunable silica–titania core and shell particle inks and inorganic polymer inks; (4) printed and optimized thermal processing with a DIW printer to produce a 6 mm diameter, 1 cm thick transparent core and shell yttrium–aluminum–garnet structures for our gain media effort; (5) engineered a tool to enable printing of higher-aspect-ratio rods; and (6) fabricated and polished conventionally to less than 4 micron flatness, a lightweight (26g), 7-cm2 mirror assembly stiffened with density-graded, coated three-dimensional printed lattices.

Publications and Presentations

Destino, J., et al. 2017. "Novel Sol-Gel Derived SiO2-TiO2 Particle Systems for Direct Ink Writing Compositionally Tailored Grin Glasses." Livermore, CA: Lawrence Livermore National Laboratory. LLNL-PRES-728230.

Dylla-Spears, R. J., et al. 2017. "3D-Printed Transparent Glass." Advanced Materials 29, no. 26 (July 12, 2017). doi:10.1002/adma.201701181. LLNL-JRNL-720419.

——— 2017. "Silica Glass with Tailored Refractive Index Profile by Direct-Ink-Writing." Livermore, CA: Lawrence Livermore National Laboratory. LLNL-PRES-731470.

Dudukovic, N., et al. 2017. "Rheological Characterization of Colloidal Silica Suspensions for 3D Printing of Optical Glass Monoliths." Livermore, CA: Lawrence Livermore National Laboratory. LLNL-PRES-723093.

Seeley, Z. M., et al. 2016. "Transparent Ceramics with Tailored Composition." 9th Intl. Conf. High-Temperature Ceramic Matrix Composites and Global Forum on Advanced Materials and Technologies for Sustainable Development, Toronto, Canada, June 26–July 1, 2016. LLNL-PRES-731631.