Michael Bagge-Hansen (15-LW-074)

Abstract

We plan to develop a new approach to producing metal foams with nanometer-scale pores by freeze-drying aerosols. Nanoporous metals are extremely compelling materials because they maintain good electrical and thermal conductivity while offering enhanced activity, tunable density, and novel electronic and mechanical behavior. Nanoporous metal particles are important to applications ranging from basic energy science to advanced manufacturing relevant to catalysis, battery and capacitor electrodes, heat sinks, hydrogen storage, filtration, and antimicrobial scaffolds. At LLNL, nanoporous metals are needed for independent control of material and density in high-energy physics experiments, as an essential ingredient for ink used in additive manufacturing of printed batteries and sensors, and for basic science experiments investigating the fundamental mechanical and chemical properties of these materials. However, they are currently very difficult to produce. We seek to understand and exploit the fundamental material science that governs the formation of nanoporous metal particles via freeze-drying through advanced characterization and process diagnostics to produce uniform nanoporous copper and gold microscopic particles with extremely high yield and high purity.

We expect to establish a very efficient method to produce uniform copper and gold nanporous microscopic particles with very high yield and high purity. We will embed in this process a number of sophisticated diagnostics as well as material characterization to reveal the fundamental physics of assembly and facilitate rapid optimization. We will establish protocols to develop optimum starting solute concentration, generation and freezing of an aerosol, vacuum desiccation, and post-processing to achieve a desirable stability, density, and porosity of a nanoporous metal foam. We expect these data to establish a knowledge base sufficient to enable predictive capabilities, with applications in catalysis and advanced manufacturing. We further believe that this research may show that the process is a much more general route to nanoporous materials than existing protocols, providing a paradigm for the production of new porous materials.

Mission Relevance

Our proposed work is positioned to expand LLNL's capability to synthesize nanoporous materials. In particular, we have focused the scope of our proposed work on copper and silver nanoporous foams because of specific demands for these materials within the Laboratory. As such, this basic research project is well-aligned with LLNL's core competency in advanced materials and manufacturing.

FY15 Accomplishments and Results

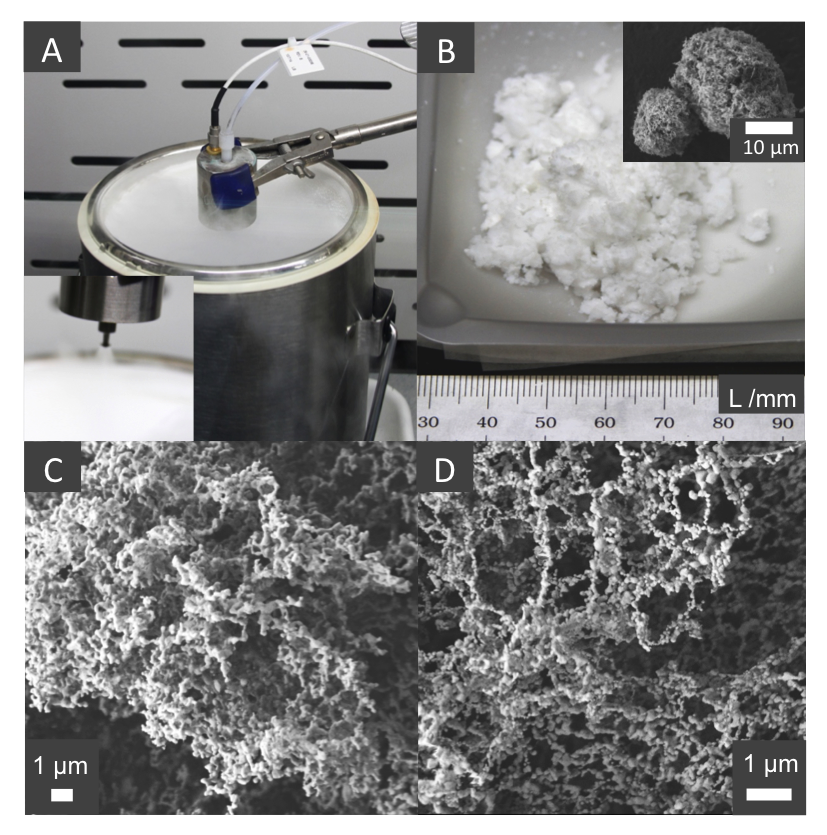

In FY15 we (1) discovered an approach to making pure silver foams that yielded results exceeding our expectations; (2) deployed air-free handling protocols and equipment for controlling humidity in production of copper nanoporous foams; (3) implemented highly controlled protocols for spray freeze-drying of metal salts, which resulted in nearly pure copper and silver nanoporous foams with size and density control (see figure); and (4) applied for a patent on these processes and protocols.