Rayford Mays | 18-FS-002

Overview

Three nondestructive inspection techniques—defocused laser-speckle imaging (DLSI), vibrothermography, and laser-based ultrasound (LBU)—were tested to determine their suitability for inspecting multilayer metallic structures of interest to Lawrence Livermore National Laboratory. The results of this feasibility study indicate that LBU and DLSI can provide information about the structure of objects of interest while requiring minimal contact and handling of the objects under test. DLSI was particularly successful at detecting machined flaws in a test sample and the internal structure of an additively manufactured (AM) part.

Background and Research Objectives

A key high-value component present in the nuclear stockpile is characterized by multiple elastic layers occasionally containing flaws at their interfaces. The current inspection method consists of destructive disassembly, a process undesirable for high-value stockpile components. X-ray radiography and conventional ultrasonic testing are unsuitable due to insufficient sensitivity (radiography) and prolonged surface contact and insensitivity to bond-strength anomalies (ultrasound). There is strong programmatic interest in developing a nondestructive inspection technique capable of detecting multiple voids and requiring minimal contact and manipulation of the part.

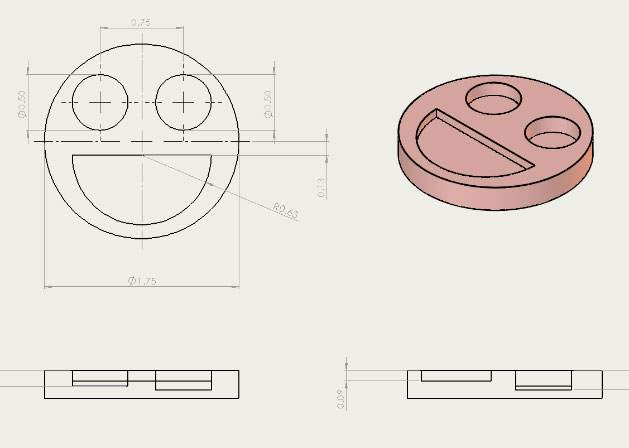

The goal of this study was to evaluate three inspection techniques: DLSI, vibrothermography, and LBU. Three samples were used for testing: a copper disc with machined features on the back face (see figure), an AM assembly with an internal network of supporting pins, and a dual-layer diffusion bonded disc.

Impact on Mission

This study supports NNSA and Laboratory stockpile stewardship goals by seeking alternatives to destructive testing techniques currently used on high-value, multilayer, metallic components to determine bond strength and to detect the presence of disbonds. The nondestructive techniques evaluated during this study could reduce inspection costs and time while increasing coverage. This research also enhances the Laboratory's core competencies in advanced materials and manufacturing and nuclear science and technology.

Conclusion

The results of this feasibility study indicate that LBU and DLSI are promising nondestructive inspection techniques for multilayer metallic assemblies. LBU would benefit from additional study on a variety of samples, including engineered disbonds between layers and samples with regions of varying bond strength. The DLSI technique successfully detected the machined feature whose resonant frequency fell within the bandwidth of the available equipment. Future work should start with more complex samples and equipment operating above 80 kHz. A modified form of DLSI for displacement performed well on an AM part, illustrating the flexibility of the technique and suggesting a path forward for rapid post-build inspection of a variety of complex parts of interest to the Laboratory.