Jack Kotovsky (17-ERD-056)

Executive Summary

Our goal is to increase the power and brightness of semiconductor laser diodes by using newly available materials and processes to address the limits of thermal management. If successful, the new isothermal liquid–vapor, phase-change heat-removal system will improve the performance of diode-pumped lasers, which supports the NNSA mission in nuclear weapons stockpile management.

Project Description

Semiconductor laser diodes are the preferred light source for pumping laser-gain media because of their high brightness and narrow emission spectra. This creates powerful and efficient laser systems. These diodes are critical for a wide variety of emerging Livermore missions including lasers for use in materials processing (such as laser peening), laser-assisted deposition and cutting, and high-average-power lasers for generating mono-energetic gamma rays. These applications push the laser diode performance envelope to fully achieve their objectives. Current approaches to mounting and cooling laser diode arrays do not meet programmatic needs. Diode lasers generate a waste-heat load comparable to their optical emission power. For this reason, the efficiency and size constraints of heat-removal technology impact the size, weight, and power of the laser subsystem and its overall utility in particular applications. We will address the fundamental limitation of all high-powered laser diode arrays—namely, thermal management. We will develop the foundation for a laser diode package that uses isothermal liquid-vapor, phase-change heat removal at the diode surface during continuous operation. Our goal is to increase brightness over state-of-the-art systems through a reduction in pitch and an increase in diode power. This will be carried out by combining new processes and materials to convey heat to the working fluid, and to employ novel, low-temperature joining to address critical thermal stress issues. We will use combined expertise in micro-electromechanical packaging, material joining, phase-change heat transfer, and laser systems to develop a solution that will enable advanced future diode use.

We expect to develop new capabilities, and create technology that will serve advanced laser applications in areas that demand high heat-flux removal, such as cooling targets in neutron generators. Non-conventional materials will be explored that offer inherent material performance advantages yet also pose numerous processing challenges. These capabilities include etching high-aspect-ratio, silicon-carbide materials and developing transient liquid-phase solders. Our research will culminate in the direct measurement of coupled thermal and light emissions performance of a five-bar diode array using industry-standard optical performance metrics. We anticipate a successful project will result in an array that will display a greater than five-fold increase in brightness over state-of-the-art laser diode systems. We intend to develop high-aspect-ratio cooling structure fabrication and testing, as well as a diode-bonding process during the initial stages of the project. We will then fabricate cooling structures with at least one additional candidate material, such as silicon carbide, and then characterize the heat-transfer performance of the cooling structure. In parallel, we will develop the low-temperature, transient liquid-phase bonding process on mock diode structures, and characterize the mechanical integrity and induced stress. These efforts will lead to the second phase of our proposed effort—the development and performance testing of an arrayed structure with multiple diode bars.

Mission Relevance

High-energy lasers are instrumental in manipulating materials and generating radiation. They have applications in high-energy-density science, additive manufacturing, detection of nuclear materials, and drivers for inertial fusion energy. Diode-pumped, solid-state lasers are well suited for these tasks because of their efficiency, robustness, and excellent beam quality and spectral characteristics at high power. Therefore, improving the thermal performance of these lasers supports the Laboratory competency in lasers and optical science and technology, and the strategic focus area in inertial fusion science and technology. This research also supports the NNSA mission in nuclear weapons stockpile management.

FY17 Accomplishments and Results

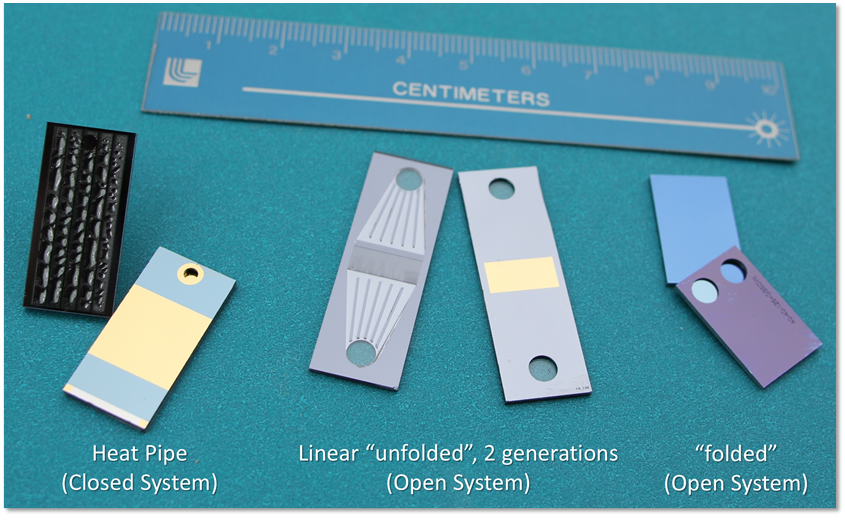

In FY17, we (1) continued cooler fabrication process development and produced a prototype folded design part that is currently being tested; (2) began testing the hardware; and (3) began modeling the overall system size, weight, and power analysis capability for applicability to stationary and mobile platforms.

Publications and Presentations

Bae, M., et al., 2017. "Micro-Textured Fin Fabrication for Enhanced Phase-hange Cooling System." Lawrence Livermore National Laboratory, Livermore, CA 2017. LLNL-POST-735660.

Bevis, T. A. and T. M. Bandhauer, 2017. "High Heat Flux Boiling Heat Transfer for Laser Diode Arrays." Lawrence Livermore National Laboratory, Livermore, CA 2017. LLNL-PRES-697121.