Christine Orme | 17-LW-006

Overview

We developed a novel method to synthesize porous nanocrystal materials that is fast, scalable, and compatible with device integration. The process first generates an emulsion of nanocrystal-laden droplets called colloidosomes and then uses an electrical field to deposit the droplets onto a surface. After the solvents evaporate, a porous film composed of hollow spheres of nanocrystals is left behind. We demonstrated that this method could be used to make films composed of metal, semiconductors, or oxide nanocrystals. In collaboration with a research group at Carnegie Mellon University, we used microrheology to explain the effect of surfactants and ligands on micron-scale liquid–liquid bubbles. We also deployed a microtensiometer at the National Synchrotron Light Source at Brookhaven National Laboratory to measure nanocrystal dynamics at the onset of jamming and crystallization. This instrument laid the groundwork for future experiments in the field of nanocrystalline films.

Background and Research

One of the most notable advances in materials science in the past two decades has been the ability to synthesize nanomaterials with a highly refined composition, size, and shape. Despite significant challenges, nanoparticles and nanocrystals have become important building blocks for materials with new functionalities. The next challenge will be to organize these building blocks into useful mesostructures. At one extreme are superlattices, dense materials composed of nanoparticles in a crystalline array. At the other extreme are rarefied nanocrystal structures, the subject of this project.

Due to their high surface area and tunability, rarefied nanocrystal structures have potential applications such as catalysis and sensors. Current methods for synthesizing these materials provide inexact control of crystallization, oxidation states, phase separation, and dispersion. For example, a typical method of synthesizing many porous catalysts uses solution impregnation of a porous scaffold (such as alumina) with metal salts. The solutions are then dried and processed in reducing or sulfiding environments to nucleate and grow nanocrystals. It is difficult to find processing conditions that simultaneously optimize the growth, stoichiometry, and distribution of multiple materials using this approach.

The challenge is to fabricate materials that simultaneously optimize the nanocrystals and the nanocrystal distribution within a porous material, particularly for multicomponent materials. Our goal was to develop new methods of synthesizing nanomaterials capable of making well-dispersed, multicomponent porous solids.

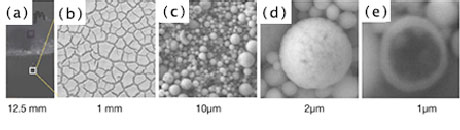

This project combined two well-established synthesis strategies to create a new class of porous materials: Pickering emulsions (Pickering 1907) and electrophoretic deposition (EPD) (Brewer 2014). Pickering emulsions are composed of two immiscible fluids, such as oil and water, in which droplets of one liquid are stabilized by particles that sit between the droplet surfaces and the continuous phase. (Colloidosomes are examples of such structures.) EPD uses electrical fields to deposit charged particles in a suspension on a substrate. We expanded this concept to deposit complex, composite colloidosomes rather than individual nanocrystals, as is more typically done. We developed this new approach to fabricate porous solids and demonstrated that porous films tens of microns thick can be fabricated in a few minutes. An example, composed of hollow colloidosomes with nickel nanocrystal shells, is depicted in the figure (images a through e ).

Porous films formed from nickel nanocrystals. (a) Optical image of a 12.5 x 25 mm electrode. ( b ) Scanning electron microscope (SEM) image of a 1 mm x 1 mm area. ( c ) SEM image of a 10 µm x 10 µm area of a film composed of hollow spheres. ( d ) SEM image of a 2 µm x 2 µm area containing one colloidosome. ( e ) Cross-section showing that the spheres are hollow. Image is 1µm x 1µm.

Impact on Mission

Our research into the development of a new method of synthesizing porous nanocrystal materials supports the advancement of the science, technology, and engineering competencies that are the foundation of the NNSA mission. This project also enhances Lawrence Livermore National Laboratory's core competency in advanced materials and manufacturing.

Conclusion

This project successfully demonstrated a new method of fabricating porous nanocrystal solids. We developed new tools to measure properties important for colloidosome formation and stability. We also constructed and tested a beamline microtensiometer. We plan to continue the beamline microtensiometer experiments at the National Synchrotron Light Source as part of an active general user's proposal.

References

Brewer, G. E. 2014. "Improved Corrosion Protection Through Electrodeposition." The Chemist 87(1): 11–13. http://www.theaic.org/pub_thechemist_journals/Vol-87-No-1/Vol-87-No1-Ar….

Pickering, S. U. 1907. "Emulsions." Journal of the Chemical Society 91: 2001–2021. doi: 10.1039/CT9079102001.

Publications and Presentations

Orme, C. A., Yu, Y., Sharkey, C. & Anna, S. 2018. Ultra-low density materials formed from colloidosomes. U.S. patent application no. PCT/US2018/57341, filed October 24, 2018.