Cheng Zhu | 18-FS-001

Overview

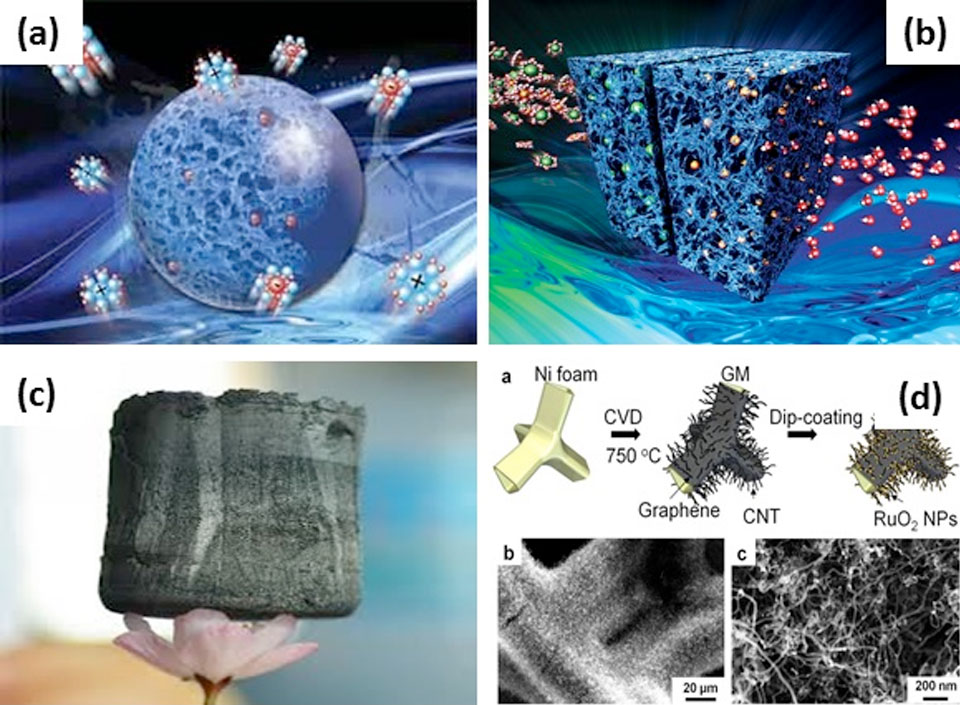

In this study, we explored the feasibility of using new methods to shorten ion transport pathways and accelerate ion transport rates in porous carbon materials by introducing other materials and manipulating the macroscale and mesoscale pore distribution. As a result, we developed an integrated strategy for fabricating carbons with directional porosity gradients for multifunctional applications through the three-dimensional printing of tailored, multicomponent materials. We fabricated the first carbon materials with tunable architectures, chemistries, and pore distributions. (The following figure shows just a few examples.) These materials are interesting for applications requiring pore directionality, such as energy storage devices and catalyst supports. This project will pave the

Some examples of porous carbon materials. ( a ) Porosity distribution of carbon materials for supercapacitors; ( b ) ion transport in porous carbon materials; ( c ) monolith of graphene aerogels made by self-assembly; ( d ) graphene network made by direct chemical vapor deposition (CVD).

Background and Research Objectives

Portable and wearable electronics necessitate high-performance, rechargeable power sources with commensurate form factors (Chmiola et al. 2010). One solution is to use energy storage devices based on micro- and nanostructured architectures, which can achieve ultra-high capacitance to attain greater energy densities while maintaining their characteristically high power densities (Simon and Gogotsi 2008). The electrode material of choice for these devices is porous carbon, which is available across multiple length scales (carbon black, activated carbons, and graphene oxide), and which has stable physicochemical properties, a low cost, and wide availability (Hao, Li, and Zhi 2013). Unfortunately, the intrinsically stochastic micro-porosity of these materials and their homogeneous composition in carbon monoliths significantly affects mass transport, ion transport, and mechanical strength. For example, carbon-based supercapacitors are known to suffer from electrode kinetic problems that are caused by inner-pore ion-transport resistance and diffusion distance. Electrolyte ions cannot easily access the pores of these materials, whose structures have twists and turns. This, in turn, negatively affects the charging rate and capacitance, especially at high current densities (Gibson and Ashby 1999). We therefore attempted to shorten the ion transport pathways and accelerate the ion transport rate by introducing other materials and manipulating the macroscale and mesoscale pore distribution (Barg et al. 2014).

Carbon-based aerogels hold large advantages over other monoliths due to their high specific surface area, good conductivity, and superior mechanical strength. Most carbon aerogels are made by self-assembly of a single material whose propensity towards aggregation and restacking significantly reduces the ion-accessible surfaces and whose narrow channels limits ion transports. Previously, several synthetic methods were developed to produce 3D carbon-based composites to overcome these limitations using the strategies of either self-assembly, direct deposition, templating, or freeze casting; however, these tailoring methods have never been integrated (Zhu et al. 2015 and 2016, Lewis 2006), and the fabrication of directional 3D carbon aerogels with multinary chemistry and hierarchical porous architectures via a controllable and scalable tuning method remains a significant challenge.

During this study, we successfully developed an integrated strategy to dually tune the composition and multiscale pores distribution of carbon aerogels to form multinary directional composites.

Impact on Mission

This study enhances Lawrence Livermore National Laboratory's core competency in advanced materials and manufacturing while serving the Laboratory's research challenge in energy and resource security. It also addresses the DOE's recent Energy Innovation Hub initiative for advanced research on batteries and energy storage.

Conclusion

We developed an integrated strategy for fabricating carbons with directional porosity gradients for multifunctional applications through the three-dimensional printing of tailored, multicomponent materials. This study paves the way to a radically new platform for fabricating directionally porous carbon-based composites utilizing a new mixing-based 3D printing technique. We demonstrated a first-of-its-kind method that combines rapid material synthesis of tailored carbon-based nanomaterials with a streamlined manufacturing approach. By integrating design, fabrication, and characterization, we can rapidly produce novel directional carbons with multinary chemistry and porosity gradients. This approach will accelerate the discovery, fundamental understanding, and product realization of advanced carbon materials. This approach enables new design concepts in energy storage technology because of the wide range of largely unexplored 3D electrode configurations.

References

Barg, S. et al. 2014. "Mesoscale Assembly of Chemically Modified Graphene into Complex Cellular Networks." Nat. Commun. 5

Chmiola, J. et al. 2010. "Monolithic Carbide-Derived Carbon Films for Micro-Supercapacitors." Science 328 , 480–483.

Gibson, L. J. and M. F. Ashby. 1999. Cellular Solids: Structure and Properties . Cambridge University Press.

Hao, L., X. Li, and L. Zhi. 2013. "Carbonaceous Electrode Materials for Supercapacitors." Adv. Mater. 7 , 3899–3904.

Lewis, J. A. 2006. "Direct Ink Writing of 3D Functional Materials." Adv. Funct. Mater . 16 , 2193–2204.

Simon, P. and Y. Gogotsi. 2008. "Materials for Electrochemical Capacitors." Nat. Mater. 7 , 845–854.

Zhu, C. et al. 2015. "Highly Compressible 3D Periodic Graphene Aerogel Microlattices." Nat. Commun . 6 .

——— . 2016. "Supercapacitors Based on 3D Hierarchical Graphene Aerogels with Periodic Macropores." Nano Lett.