Larry McMichael (16-FS-015)

Project Description

Threats using high explosives continue to evolve as terrorist means and methods adapt to attempt to circumvent detection at security checkpoints, checked luggage, and cargo. The potential risk from advanced manufactured high explosives could be even greater if technology enabled the explosives to be integrated into the material structure of benign-looking objects to further reduce the chances of detection. In addition, physical differences between advanced manufactured high explosives and traditionally manufactured explosives may affect detonation characteristics. These differences could also produce differing x-ray signatures. We are determining the feasibility of using detonability of high explosives created by advanced manufacturing as a function of density to establish which densities are viable explosives, and compare x-ray signatures of advanced manufactured explosives with those traditionally manufactured. Using x-ray computed tomography data, we will identify differences in the samples and evaluate whether there are correlations in the x-ray signatures that could be used to discriminate between detonating and non-detonating samples and between traditional and advanced manufactured high explosives. Possible physical differences between the two are void content, density distribution, and layer separations between subsequent passes of the advanced manufacturing material-deposition process. Information gained from this feasibility study would provide insight into the critical advanced manufacturing characteristics that could affect detonation characteristics.

Our feasibility study could help evaluate the risk of high explosives produced by advanced manufacturing by examining which explosive densities pose a threat and whether those formulations have different x-ray signatures than traditionally manufactured explosives. Altered signatures could shift advanced manufactured high explosives outside the detection envelope established for traditionally manufactured explosives. We will first investigate the detonability of advanced manufactured high explosives with respect to density. In conventional explosives, the propensity to detonate, and thus the concomitant destructive effect, typically decreases with density. For advanced manufactured explosives, this density threshold is entirely unknown. Next, we will determine the feasibility of using x-ray computed tomography signatures of advanced manufactured explosives to compare with the signatures of a traditionally manufactured (e.g., cast or pressed) sample. We will analyze the x-ray data to evaluate how much sample-to-sample variation exists and how physical variations from the different manufacturing processes could affect x-ray signatures. Differences in x-ray signatures would be examined for correlations to detonability as well as the manufacturing method.

Mission Relevance

This feasibility study directly supports the Laboratory's core competency in advanced materials and manufacturing, by addressing the synthesis and prediction of the behavior of novel advanced manufactured materials. In addition, high-explosives materials are relevant to the Laboratory's strategic focus area in stockpile stewardship science.

FY16 Accomplishments and Results

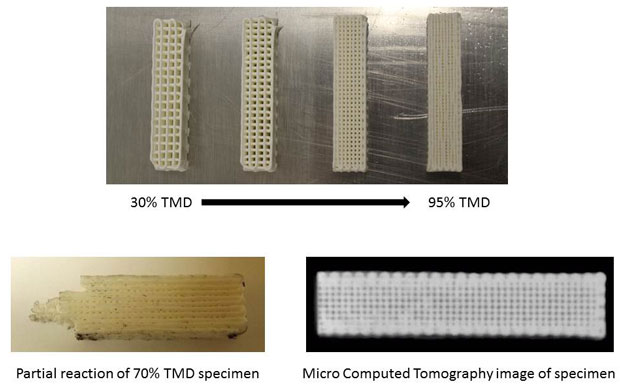

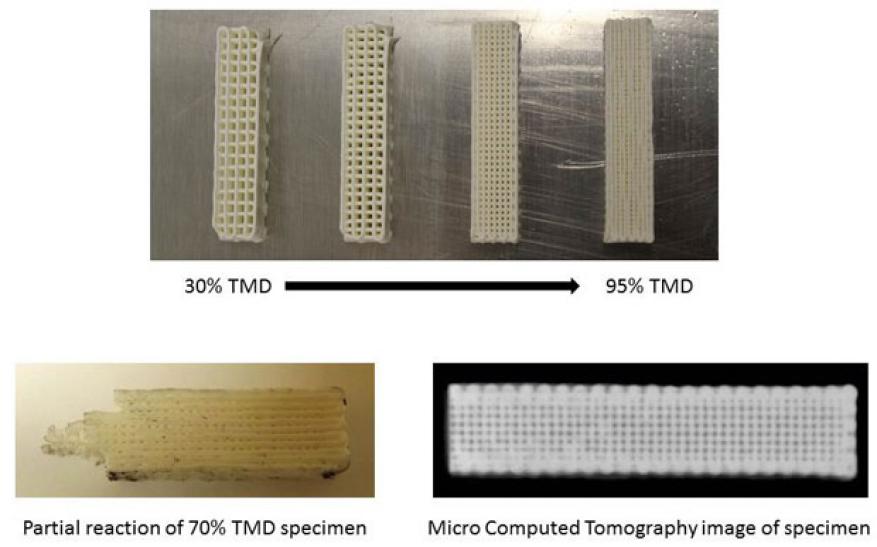

In FY16 our efforts focused on (1) initial fabrication of advanced manufactured high-explosive specimens, (2) collecting radiographic properties of the specimens, and (3) detonation testing to determine where the detonation boundary lies for advanced manufactured high explosives. The advanced manufactured specimens were produced using the high-explosives compound LX-20 in a direct ink write machine, and their density ranged from approximately 40 to 95% of theoretical maximum density (shown in figure).