Adam Conway | 17-ERD-105

Overview

High-power microwave (HPM) directed energy is a potential component of next-generation offensive and defensive warfare systems for the U.S. military. The drawback of traditional tube-based HPM systems has been their inherently large size, weight, and power requirements and their fixed, narrowband frequency content. Advances in photo-conductive semiconductor switches (PCSS) pioneered at Lawrence Livermore National Laboratory (LLNL) have demonstrated the exciting potential for semiconductor-based HPM sources with extreme power density, waveform agility, modular scalability, and high repetition rates. Much previous research has focused on the semiconductor device component, but innovations in laser driver technology in terms of high peak power, efficiency, and compactness are required to fully realize the potential advantages of the technology. This project aimed to greatly increase the laser power density by developing a custom fiber laser for our PCSS technology. With this tool, we can explore new areas of the microwave parameter space previously unachievable by conventional HPM technology. In this project, we demonstrated a 50-fold reduction in laser volume, a 500-fold increase in repetition rate and, for the first time, a high-power PCSS operating at 50 kHz.

Background and Research Objectives

Over the past six years, LLNL has demonstrated the feasibility of semiconductor-based, megawatt-class, radio frequency (RF) power generation using wide-bandgap silicon-carbide (SiC) PCSS driven by a modulated solid-state laser. We call this technology "LEOPARD," for "LLNL electro-optical, high-powered, agile, radio frequency, directed-energy source." At the heart of the technology is the vanadium-doped SiC, which enables exceptional standoff voltages (>30 kV), high currents (>400 A), linear response, rapid on/off switching (< 50 ps), and a wide range of frequencies (DC to GHz).

The main obstacle to the widespread adoption of this technology is the large size of the laser relative to the smaller switch, which results from low laser efficiency combined with poor use of incident light absorbed within the semiconducting material. This unique material has features that make it ideal for high-power switching at up to GHz frequencies. Because the V dopant is on the order of 1–100 ppb, the absorption coefficient is on the order of 0.01–1 cm -1 . This enables bulk excitation of substrates exceeding 1 mm in thickness. The bulk illumination, in turn, uniformly promotes electrons (holes) throughout the material into the conduction (valence) band, where it can then contribute to the current. When the light is removed, the response time of the switch is governed by the recombination time of the electron (hole) back into the vanadium (V) level. Depending on the concentration of V, this time can vary from <50 ps to 10 ns, enabling operation in excess of 10 GHz. In addition, extremely high voltages can be applied to the switch, owing to a combination of the high critical electric field (2.5 MV/cm) and large thickness (1 mm or more) from bulk illumination. Switching powers on the order of 6.4 GW/cm 3 at 500 MHz with 100-Hz repetition rate have been demonstrated.

LEOPARD enables a wide degree of flexibility in the output frequency as the semiconductor switch directly reproduces the waveform of the incident laser at speeds approaching the carrier lifetime. For this reason, the same system can be used to scan and target specific frequencies.

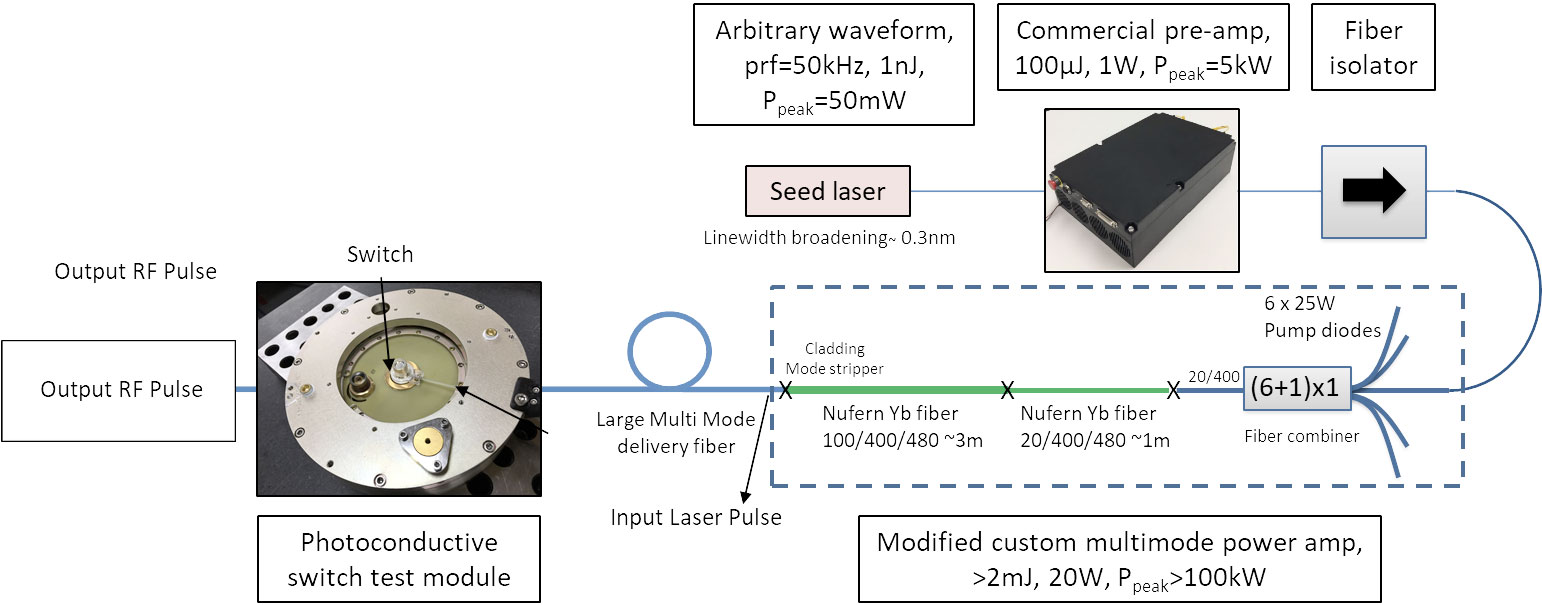

Because of the complex requirements for the laser (combining pulse-shape agility in amplitude and time with high peak optical powers of 4 MW), a commercial solution does not exist; thus, the main emphasis of this project was on designing and building custom fiber laser systems. The figure below illustrates a conceptual design. Furthermore, in order to minimize reflections back into the laser, which could propagate through the fiber and destroy the functionality, we developed and demonstrated a one-step, plasma etching technique to roughen the SiC surfaces, resulting in a <1% reflectivity at the SiC surface while maintaining >95% transmission. Finally, we improved the laser utilization efficiency by properly co-doping the SiC PCSS.

Impact on Mission

This technology is intended for use as an RF–microwave directed-energy source. High-power RF directed energy is a potential component of the next generation of offensive and defensive warfare systems for the U.S. military. With broad application in defense, intelligence, and homeland security. It has the potential for use in high-RF power generation at significantly reduced system size and weight, but increased power. This could enable new applications for a compact communications microwave transmitter for free space satellite communications for cybersecurity, space, and intelligence, as well as a novel compact laser design in support of the Laboratory's core competency in lasers and optical science and technology.

Conclusion

The completion of this project significantly reduces the risks associated with reliability, as well as size, weight, and power, by extending the performance, lifetime, and operability of the laser drive component of an ultra-compact, frequency-adaptive, waveform-agile, photoconductive, switch-based, high-power, RF directed-energy technology. We demonstrated a 50-fold reduction in the volume of the laser, a 500-fold increase in repetition rate and, for the first time, a high-power PCSS operating at 50 kHz. With this tool, we can explore areas of the microwave parameter space previously unachievable under conventional HPM technology.

Publications and Presentations

Bora, M., et al. "Illumination of Photoconductive Silicon Carbide Semiconductor Switches Using a Total Internal Reflection Optical Trap." Applied Physics Letters (in preparation). LLNL-JRNL-764480.

Kramer, N., et al. "Total Internal Reflection in SiC Photoconductive Semiconductor Switches for Reduced ON-State Resistance." Abstract submitted to GOMACtech . LLNL-ABS-758987.