James Lewicki (15-ERD-030)

Abstract

Fiber-reinforced composite materials represent a key enabling technology for stockpile applications requiring high strength or stiffness and low weight. These materials, however, are limited by the shortcomings of current design and fabrication methodologies. Additive manufacturing of composite materials will reduce build times, infrastructure, and cost and lead to new advancements in the scientific understanding of composite performance. We plan an investigation of three-dimensional printing techniques coupled with computational design optimization and chemical tailoring with the aim of establishing a robust capability for the design and development of additively manufactured fiber-reinforced composites. By leveraging our expertise in synthesis, additive manufacturing, and characterization, we will enable development of fiber-reinforced polymer composites through deployment of a combined chemical, computational, and engineering approach to the control of composite mesoscale (intermediate-scale) structure in three dimensions.

We expect to develop the capability for rationally designing (through computational optimization) and additively manufacturing carbon fiber and polymer composites with unprecedented control over the orientation of fibers and composite mesoscale structure. Such additively manufactured composites will have physical properties that match or exceed those of conventional aerospace-grade carbon-fiber systems and have significantly less part-performance uncertainty. We will demonstrate the ability to produce complex parts with geometries that are unobtainable using conventional manufacturing methods, and advance the state of the art in carbon-fiber additive manufacturing, computational optimization, and understanding of composite mesoscale structure and interfacial chemistry in relation to macroscale performance. The results will be of immediate significance, both to the Laboratory and to the broader scientific community, because they will represent the first unified approach to rational design and implementation of optimized fiber-reinforced composite structures produced with additive manufacturing.

Mission Relevance

The need to minimize uncertainty in the nation's nuclear stockpile requires that materials perform well, be well understood, and be easy to design and model. Rational additive manufacturing of fiber-reinforced composites has applications to stockpile science and beyond. This research is important to meeting increasingly constraining requirements for future stockpile life-extension programs and aligns well with the central Laboratory strategic focus area in stockpile stewardship science and core competency in advanced materials and manufacturing.

FY15 Accomplishments and Results

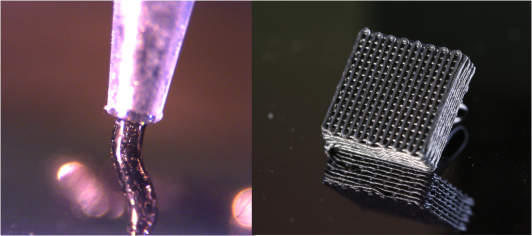

In FY15 we (1) demonstrated the synthesis and application of a novel epoxy–resin system that is compatible with carbon-fiber and real-time additive manufacturing printing, and has final mechanical properties comparable to areospace materials; (2) demonstrated additive manufacturing printing technology that allows the manufacture of novel short composites based on carbon fibers with unprecedented control of fiber orientation—the composites are 40% stronger in tensile mode than equivalent conventional composites, stronger in a compressive mode, and show orthotropic mechanical response and orthotropic electrical properties; (3) demonstrated proof of concept for printing continuous fiber with control of alignment using a novel LLNL resin; (4) implemented basic operational gradient-optimization routines in NIKE3D (mechanical deformation code) for the carbon-fiber systems; and (5) submitted three records of invention.Publications and Presentations

- Lewicki, J. P., et al., Toward rationally designed, additively manufactured carbon fiber composites with optimized mesostructures and orthotropic macroscale properties. Pacifichem, Intl. Chemical Congress of Pacific Basin Societies, Honolulu, HI, Dec. 20–25, 2015. LLNL-ABS-675673.

- Rodriguez, J. N., et al., Additively manufactured multifunctional bio-based composites. (2015). LLNL-ABS-678605.

- Worsley, M. A., and J. P. Lewicki, Advanced carbons for structural and energy applications. (2015). LLNL-PRES-674206.