Anthony Van Buuren (14-ERD-067)

Abstract

Ultrahard materials are relevant to Livermore's National Ignition Facility for ignition targets, the Department of Defense for wear-resistant coatings, and the Defense Advance Research Projects Agency for low-temperature diamond growth. Chemical vapor deposition has attracted significant interest for the preparation of ultrahard coatings, yet characterization has largely been conducted post-synthesis, which restricts understanding of growth mechanisms because the surface environment changes during deposition. Developing a means to deposit ultrahard coatings with high spatial resolution and at low temperature on three-dimensional structures would represent a completely new capability that can be readily integrated into the additive manufacturing effort at Lawrence Livermore. Our research project combines unique Laboratory-based, laser-assisted chemical vapor-deposition synthesis with x-ray-based in situ characterization to tackle this problem. Our synthesis method could provide a versatile approach for ultrahard film synthesis with precise control over the location of deposition, and the in situ method enables a comprehensive characterization of the film structure at all stages of growth.

We expect to establish an x-ray-based in situ diagnostic for coating process control and rapid prototyping of ultrahard coatings. By rapidly exploring chemical and structural properties of candidate ultrahard materials with our laser-assisted diagnostic cell for chemical vapor deposition, we expect to achieve a better understanding of these materials over short time periods. We will develop a predictive understanding of coating growth and resulting film structure and robustness, and will produce spatially selective coatings of ultrahard materials. We are confident that the research will attract the interest of the oil and gas service sector in the ability to produce designer coatings of materials such as diamond, boron carbide, and boron carbon nitride for diverse applications such as high-wear parts in pumps, drill bits, and other mechanical surfaces; materials that experience extreme chemical or thermal environments; and mission-critical parts.

Mission Relevance

Our new laser-assisted chemical vapor-deposition capability and in situ diagnostics expertise supports the Laboratory's additive manufacturing efforts to produce unique materials. Research into ultrahard, fracture- and corrosion-resistant materials falls squarely in LLNL's advanced materials and manufacturing core competency, especially with regard to development of new materials and partnership building.

FY15 Accomplishments and Results

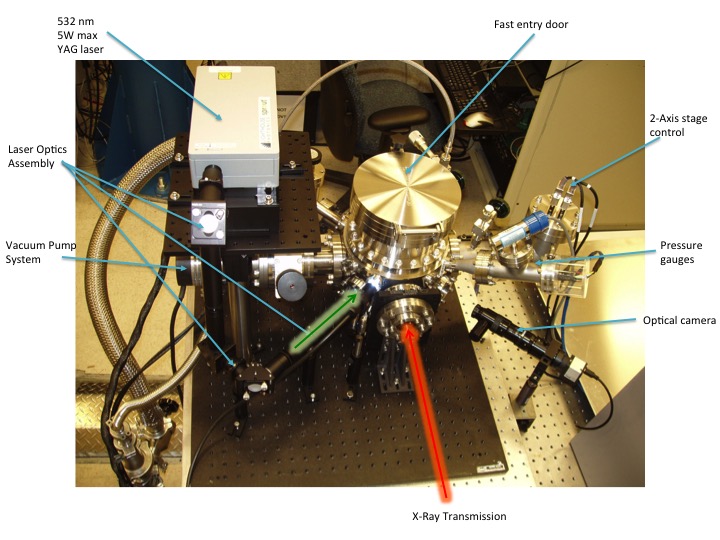

In FY15 we (1) resolved the sodium contamination problem in diamond-like carbon grown with laser-assisted chemical vapor-deposition—the carbon films have been synthesized as a function of laser power on both silicon carbide and silicon dioxide substrates; (2) established this growth system for boron carbide at the University of California's Berkeley Nanolab; (3) completed assembly of the portable vacuum, laser-assisted chemical vapor-deposition system for use in combined small-angle scattering and vapor deposition experiments on the growth of diamond at the Advanced Light Source at Berkeley (see figure); and (4) performed the first-ever in situ x-ray Raman experiments in which we were able to measure the density of electronic states for the carbon 1s electron configuration and monitor carbon chemistry during the breakdown of precursors and growth of nanometer-scale carbon particle structures.