Nerine Cherepy | 17-ERD-114

Overview

Light-emitting optical materials can concentrate light by confining wide-angle emitted light into a high refractive index plane. Using these materials, we explored the use of direct ink-writing, spin casting, and cold-pressing to produce spatially controlled ceramic green bodies (unfired, unsintered clay objects), which were subsequently consolidated and sintered into structures with the low optical scatter and high light confinement required for high-performance light guides. Using this method, we built two light guide structures. The first, a luminescent solar concentrator, is a planar light guide that concentrates solar irradiation impinging on a flat plate via total internal reflection into small edge-mounted solar cells. The second, a planar waveguide laser amplifier, is a device for guiding optical waves to boost a laser's power and is an option for compact high-power laser designs.

Background and Research Objectives

We built two light guide structures: a luminescent solar concentrator and a planar waveguide laser amplifier.

The Luminescent Solar Concentrator

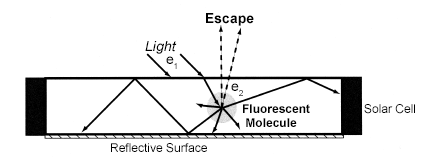

Our first product was a luminescent solar concentrator. To decrease cost and increase efficiency, standard solar cells can be optically coupled to the edge of a luminescent solar concentrator, a large-area, optically transparent plate in which the broadband diffuse solar spectrum is absorbed by dispersed luminophores (luminescent substances). Absorbed light is re-emitted at longer wavelengths and coupled to the edges of the plate by total internal reflection. One or more small solar cells are edge-coupled to the plate to achieve solar concentration; the standing record for these devices is ~10× concentration, using dye-doped plastic plate concentrators, but 100× concentration is estimated to be possible. Figure 1 describes the basic operating principle of the luminescent solar concentrator (Yablonovitch et al. 2012, Smestad et al. 1990).

We developed methods for deposition of thin but fully optically absorptive layers of UV-visible absorbing and yellow-red emitting phosphors on glass. Several phosphors were tested, in particular focusing on low refractive index hosts, such as nitrides.

The Planar Waveguide Laser Amplifier

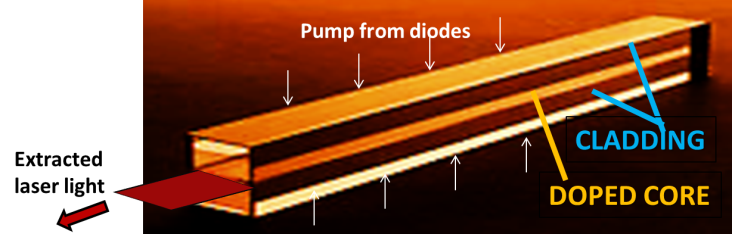

While methods such as single-crystal growth and glass fabrication of laser gain media are well-established, transparent ceramics approaches offer functional opportunities not afforded to structures grown from a melt. This is particularly true regarding spatially distinct optical structures. We speculated that transparent ceramics methods could be used to produce better performing waveguides, so for this effort, we targeted a novel laser gain media configuration for high-power compact lasers called a planar ceramic waveguide laser (Shepherd, et al. 2001, Lee et al. 2001), specifically, an yttrium-aluminum-garnet waveguide laser. A waveguide laser amplifier design in which at least one dimension is intended to operate in a natural single-mode (whereby light travels only in one direction) offers the following advantages: enhanced optical gain, a low lasing threshold, passive mode control, and excellent thermal management in a small footprint. Figure 2 shows the optical configuration of a PWG.

To fabricate thin (100–200 um) waveguides, we utilized both direct-ink-writing (DIW) and pressed green bodies assembled into planar structures.

Impact on Mission

Through this project, we expanded the Laboratory's already strong capability in transparent ceramics into laser gain media and optical concentrators. The creation of novel ceramic green bodies supported the Laboratory’s core competency in advanced materials and manufacturing. As a result of this research, a wide range of ceramic optics can be pursued, with applications in defense, non-proliferation, energy efficiency, and renewable energy. In particular, our efforts to demonstrate light-guiding in phosphor ceramics are relevant to the Phosphor project at The Ames Laboratory's Critical Materials Institute.

Conclusion

Interest in Livermore’s transparent ceramics capability has led to seed funding from the DOD Joint Technologies Office and opportunities to continue our research in ceramic gain media.

References

Lee, J.R., et al. 2001. "A Nd:YAG Planar Waveguide Laser Operating at 121W Output with Face-Pumping by Diode Bars, and Its Use as a Power Amplifier," Proceedings of Advanced Solid-State Lasers. OSA Publishing.

Shepherd, D.P., et al. 2001. "High-Power Planar Dielectric Waveguide Lasers." J. Phys. D: Appl. Phys. 34, 2420–2432.

Smestad, G. et al. 1990. "The Thermodynamic Limits of Light Concentrators," Solar Energy Materials 21, 99–111.

Yablonovitch, E., et al. 2012. "The Opto-Electronic Physics that Broke the Efficiency Limit in Solar Cells" 38th IEEE Photovoltaic Specialists Conference, Austin, TX., June 2012. doi:10.1109/PVSC.2012.631789.