Regina Soufli (17-SI-001)

Executive Summary

We are developing an understanding of the physics of layer interfaces by investigating their physical and chemical properties, especially pertaining to ultrathin coatings on multilayer dielectric mirrors found in high-power laser systems. The goal is to improve coatings to extend the lifetime and performance of high-average-power pulsed-laser systems for scientific applications and lasers for emerging directed-energy systems.

Project Description

Multilayer interference mirrors are important components in imaging systems operating at infrared to hard x-ray wavelengths. These mirrors have periodic or aperiodic structures of alternating thin-film layers of two or more materials deposited on an optical substrate. The constructive interference between the layers results in efficient reflectance at incidence angles ranging from grazing to near-normal. X-ray multilayers are components of imaging and illumination systems, reflective filters, grating spectrometers, and polarizers. Multilayer dielectric mirrors are found in high-power laser systems or beam combination, beam steering, wavelength separation, and diffraction gratings. However, the multilayer coatings can limit system performance. For example, in x-ray imaging, the performance of ultra-short-period, hard x-ray aperiodic multilayer coatings on interference mirrors is limited by layer-interface complexity that cannot be predicted or controlled, and high-performance laser systems are often limited by the resistance to damage of their multilayer dielectric coatings. We are investigating the physical and chemical properties of ultrathin layers and their interfaces, the mechanisms that govern damage in multilayer dielectric coatings at high energy and short wavelengths, and the relationship between processing conditions and performance for both applications. This work will guide development of strategies to dramatically improve coating performance for mission-relevant challenges.

We are developing an understanding of physics at the layer interfaces to achieve new multilayer coatings with custom-tailored properties for national security applications. We intend to provide an experimental and theoretical understanding of the behavior and physical and chemical properties of ultrathin multilayer films and their interfaces. We will also identify degradation mechanisms related to processes occurring between the layers or ambient environmental exposure. We will clarify the nature and origin of multilayer dielectric laser damage precursors for high-fluence, short-wavelength lasers. Finally, we will develop and test process modifications during and after deposition to advance state-or-the-art coating performance. We will leverage Lawrence Livermore National Laboratory expertise in multilayer thin-film science, laser-matter interaction science, the material science and design of optical interference coatings, and computer simulations, along with the infrastructure in specialized deposition systems, laser testing capabilities, metrology, and diagnostics facilities. This work will guide development of strategies to dramatically improve coating performance for mission-relevant challenges.

Mission Relevance

This project supports the NNSA goal of strengthening the science, technology, and engineering knowledge base. Improved coatings that help extend the lifetime and performance of high-average-power pulsed-laser systems for scientific applications and lasers for emerging, directed-energy systems supports the Laboratory's lasers and optical science and technology core competency while also enhancing the space security research challenge.

FY17 Accomplishments and Results

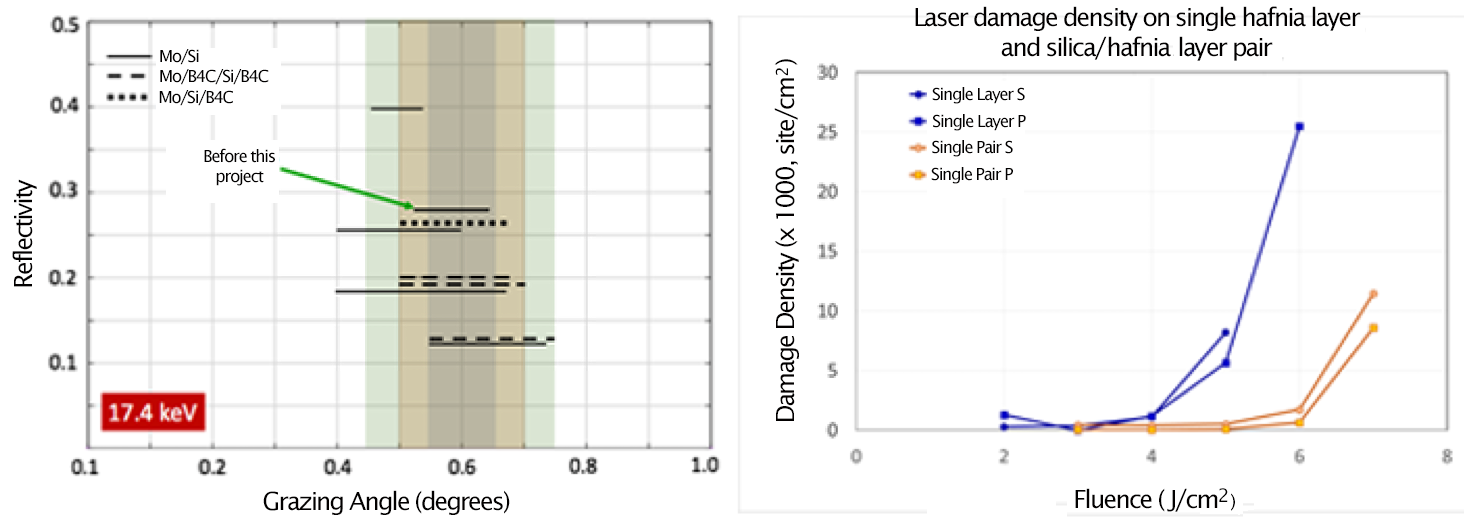

In FY17, we (1) began to create a library of new aperiodic multilayer coatings tailored to national security applications; (2) developed molybdenum/silicon multilayer films with unprecedented reflectance and field of view at 17 keV; (3) introduced deposition modifications to improve performance; (4) began developing tungsten/silicon, tungsten/silicon-carbide, and nickel(V)/silicon-carbide multilayers for 17 to 35 keV; (5) fabricated electromagnetically enhanced physical vapor deposition and ion-beam-sputtering dielectric coatings; (6) discovered that ion-beam sputtering coatings have much weaker photoluminescence and that the hafnium oxide layer has non-stoichiometric composition; (7) performed pulsed laser (10 ns, 30 ps, and 1,053 nm) damage testing of coatings; (8) set up a simulation to quantify the impact of coating defects on laser damage; (9) upgraded diagnostic systems; and (10) installed an onsite ion-beam sputtering system.

Publications and Presentations

Qiu, S. R., et al. 2017. "Deciphering Mechanistic Sources of High-Power Laser Induced Damage in Dielectric Coatings Fabricated by Ion Beam Sputtering Method." SPIE Laser Damage 2017. LLNL-ABS-730463.

Qin, R., et al. 2017. "Toward Understanding the Laser Performance of Hafnia Thin Film at 355nm Using the Single Layer and Layer Pair Platform." LLNL-PRES-738844.