Paul Pax (14-ERD-078)

Abstract

In this project, we investigated novel materials and structures for short-wavelength fiber-laser sources. Such sources are desirable for the reduced diffractive spreading of their output beams and for accessing application-specific wavelengths. Furthermore, ongoing developments in short-wavelength diode lasers for data storage and display technologies present an opportunity for power and efficiency scaling of visible fiber lasers based on novel dopant species.

Our efforts focused on samarium-doped fibers, pumped at 450 nm and emitting at 651 nm, and neodymium-doped fibers operating on the 3-level transition around 925 nm. While the samarium work was thwarted by material deficiencies, the neodymium work resulted in a novel waveguide design, exceptional lasing results, a peer-reviewed publication, and a patent application. This waveguide design has already found application in two Laboratory fiber projects.

During the course of this project, we initiated an effort to demonstrate a large-core ribbon fiber as a path toward larger mode sizes. As part of this effort, we developed a process for homogenization of doped glasses, as the index uniformity necessary for maintaining mode control (good beam quality) in large core fibers is beyond the capability of standard glass-manufacturing techniques. The resulting fiber showed very good lasing and modal properties, validating both the ribbon concept and the homogenization process.

Background and Research Objectives

Fiber-based lasers are an attractive and maturing technology, offering unmatched beam quality, efficiency, thermal management, and reliability. These lasers currently operate almost exclusively in the near- or mid-infrared region of the spectrum, primarily due to the availability of pump diodes in the near infrared. Extending fiber lasers to the visible will open a new technology arena for such sources, with benefits to applications requiring concentrated power (beam delivery, directed energy) or specific wavelengths (displays, marine communications, astronomical guide stars). With the advent of short-wavelength diode lasers, we see an opportunity to develop novel dopant species, such as samarium, emitting at 651 nm, or terbium, emitting at 546 nm.

We also consider unusual transitions in otherwise well-developed species, specifically the 3-level transition in neodymium, with tunable emission around 925 nm. While this wavelength is still firmly in the near infrared, it is of interest as a source for underwater communications via second harmonic generation (SHG). For this purpose it is essential to operate in the blue-green portion of the spectrum for best transmission through water and to target specific narrow wavelengths for use with atomic line filters.

In FY15, we initiated work on a ribbon fiber, growing out of an idea originally proposed here at Livermore.1 While not directly related to the short wavelength work, it is compatible with it; and one of the required processing steps, homogenization of the doped core material, was critical also to the waveguide design we chose for the 3-level neodymium fiber laser.

Essential to all these efforts are rare-earth, doped-silica starting materials. While there are industrial suppliers capable of producing such materials, most of them are highly focused on the most commercially significant ones and are unwilling to devote resources to custom requests. For that reason we had to expend significant efforts on finding and evaluating vendors willing to work with us.

Scientific Approach and Accomplishments

As mentioned above, central to all these efforts is a supply of rare-earth doped-silica glass. We engaged two different vendors: Hereaus, a well established supplier of telecom-grade fused-silica materials, and Optacore SA, a smaller vendor using the chelate-doping process capable of producing relatively large volumes of doped glass.

Hereaus supplied us with a small volume sample of neodymium-doped silica fabricated via a new experimental process they are investigating. From this sample, we fabricated simple step-index test fibers to evaluate the fiber attenuation and potentially the laser performance. Unfortunately, despite extensive exploration of the fiber draw parameters on our part, these fibers all displayed very high background losses. We achieved laser action on the strong 4-level transition at 1060 nm, but with only a very poor slope efficiency of 20%.

Optacore also supplied us with neodymium-doped silica material. This was purchased as part of a joint development effort resulting in multiple test samples and a final large-volume item. The background attenuation on this last item was roughly 5× lower than the Hereaus sample, though still higher than we would expect from a fully developed process. Laser testing with this material on the 4-level transition resulted in a 40% slope efficiency. Subsequent neodymium-doped materials from Optacore using better starting materials yielded improved background losses and lasing efficiency.

In what follows, we address the three different fiber types (samirium, ribbon, and neodymium) developed during this project.

Samarium

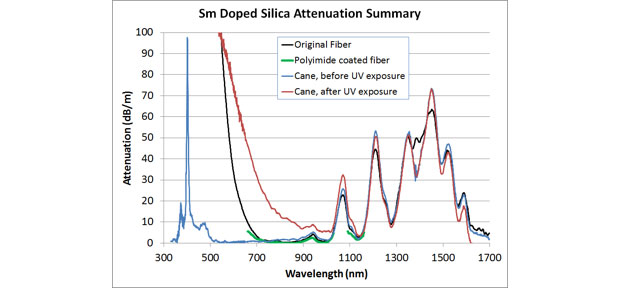

There have been few previous reports on samarium-doped fibers, and for determining our glass recipes we relied substantially on the work of Ainslie (1988) and Farries (1990).2,3 Our analysis of the literature and conclusions regarding the preferred samarium doping and glass recipe were summarized in a Laboratory internal report.4 There we specified a recipe including aluminum and phosphorus co-dopants, which contrasts with the recipe of Farries, but in the expectation that these would lead to improved samarium solubility in silica and reduced photo darkening. We purchased glass material with this recipe from Optacore as a preform or cylinder suitable for drawing, then fabricated a step-index fiber from it. This involved drawing the preform to canes (smaller-diameter cylinders or rods), over-sleeving the canes in a pure silica tube, then drawing the canes to fiber. Unfortunately, the drawn fiber showed extremely high background attenuation below 700 nm, rendering it useless. Surprisingly, the canes drawn earlier showed no such background loss, only the expected absorption lines around 400 nm and above 1000 nm. Hypothesizing that the ultraviolet lamp used to cure the coating on the fiber might be damaging the host glass, we exposed a piece of cane to that lamp and observed a similar runaway attenuation in the visible. We then drew a new fiber, this time coating it with a thermally cured polymer, avoiding ultraviolet exposure altogether. Again, this fiber showed signs of absorption in the visible. The above observations are summarized in the plot below (Figure 1). Finally, we purchased another samarium-doped preform, following the recipe of Farries3 as best we could determine. However, funding and scheduling constraints precluded our testing this material, and the question of absorption in these fibers remains unresolved.

Ribbon Fiber

In FY15, we pursued a promising fiber design, the ribbon fiber. The ribbon, described in the original Livermore proposal1 and demonstration,5 has advantages in mode size and thermal properties and is expected to be a path to power scaling for fiber lasers and amplifiers. Although not directly concerned with short wavelength operation, the ribbon fiber of this work was based on the photonic crystal fiber (PCF) structure, which requires core material with an index uniformity beyond the capability of standard glass manufacturing techniques. Because our effort to realize amplification on the 3-level transition of neodymium (see below) was to be based on the PCF structure, it would also require homogenized core material. We developed a process to suitably homogenize doped glasses.6

The ribbon fiber addresses the problem of power scaling limits set by mode size in round fibers.7 The basic idea is to increase mode size by relaxing the requirement that the fiber be single mode, choosing the geometry, doping, and deployment such that the fiber still operates preferentially in a single mode. In the ribbon the mode size (and count) is increased in one dimension only, the doping is arranged such that gain favors a single, higher order mode in that direction, and the fiber is coiled in such a way that bending acts only in the orthogonal, single-mode direction. For this project, we designed, fabricated, and laser tested such a PCF ribbon fiber.

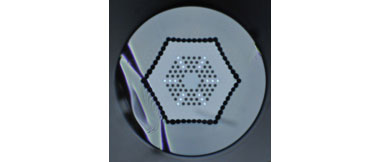

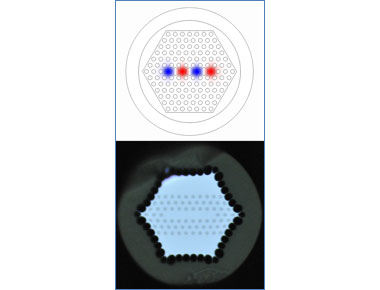

Our ribbon-fiber design comprises a hexagonal lattice of index depressions in which the core is formed by replacing a row with a material of uniform index that matches the lattice background. The fiber is essentially single mode in the narrow dimension and supports a set of modes in the wide dimension. Specifically, the background glass is pure, fused silica; the index depressions are on a pitch of 9.14 μm, have a numerical aperture (NA) of 0.14 with respect to silica, and have a diameter of 0.533 times the pitch. The core is seven lattice sites (64 μm) across, and supports six modes. The fourth mode has intensity peaks at every other core site, and these sites are doped with ytterbium (and homogenized in index); this tailoring of the gain profile results in a gain for the fourth mode that is nearly twice that of the other modes. A schematic sketch of the fiber cross section and the field of the fourth mode is shown in Figure 2, along with an image of the fabricated fiber. The dark hexagonal boundary is a ring of air holes that define a pump cladding.

Figure 2. Cross section of the modeled (top) and fabricated (bottom) hexagonal ribbon fiber. The dark boundary in the fabricated ribbon fiber is a ring of air holes that define a pump cladding.

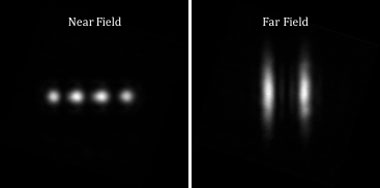

We conducted laser testing with a 9-m length of this fiber, coiled to a 1-m diameter. The cavity consisted of the Fresnel reflection from the cleaved fiber, and an external high reflector with coupling optics at the opposite end of the fiber, which was end-capped to reduce feedback. Note that the tailored gain profile was the only mode-selective element in the cavity. Pumping with up to 56 W at the ytterbium absorption peak at 976 nm yielded 33-W output, a slope efficiency of 87%, and a stable mode with four lobes. The near- and far-field beam profiles are shown below.

Neodymium

The most common lasing transition in neodymium, the 4-level one around 1060 nm, is just one of several, including the 3-level transition around 925 nm. Efficient and scalable operation on these other transitions requires suppression of the dominant 4-level transition. We have developed a novel waveguide that provides distributed spectral filtering, capable of suppressing transitions that would otherwise interfere with the one of interest.

With an active fiber based on this design, shown in Figure 4, we built a neodymium-doped fiber laser operating at 925 nm, with an output of 12 W and 55% slope efficiency with 808-nm pumping; and at 27 W and 35% slope efficiency with 880-nm pumping. These results are on par with the best previously reported, and in contrast to those previous results, we have not yet reached power scaling limits.

Figure 4. Cross section of the spectrally filtering fiber fabricated for the shortwave neodymium effort.

The novel waveguide and lasers results demonstrated in this work led to a peer reviewed publication6 and patent application.8 We refer the reader to this publication for more details.

This work has already generated a spin-off project under separate funding, investigating the utility of this waveguide to a neodymium amplifier operating around 1425 nm, which is of great interest to fiber telecommunications. This work has resulted in a peer-reviewed publication9 and a patent application.10

Impact on Mission

High-power, short-wavelength fiber lasers benefit defense technologies, specifically in the areas of directed-energy systems and secure communications. The success of this project supports a central Laboratory strategic mission in defense and a core competency in lasers and optical science and technology. Success also benefits scientific applications, such as guide stars for astronomy and sources for high-brightness color displays.

Conclusion

One of the main goals of this project was to demonstrate a samarium-doped fiber laser. Unfortunately, we were unable to achieve this, due to an unforeseen and as yet unresolved material processing issue, specifically the degradation in short-wavelength transmission of the samarium-doped glass when drawn to fiber.

However, the search for a supplier capable of providing high-quality, large-volume preforms doped with samarium and other rare dopants has led to the successful development of a new and valuable vendor, Optacore SA. They have now supplied multiple preforms with a variety of dopants. Two other successful tasks of this project, the ytterbium-doped ribbon fiber laser and the short-wavelength neodymium fiber laser were both enabled by material from Optacore.

The added scope of the ribbon fiber task was a demonstration of a Livermore-originated concept that enables power scaling of fiber lasers and has already led to external funding for a project to develop it further.

The power-scalable, short-wavelength, neodymium-fiber laser at 925 nm was likewise the realization of a Livermore-originated concept and demonstrated a novel and versatile method for distributed in-fiber spectral filtering, as well as the renewed utility of neodymium as a fiber-laser-active species; its success has resulted in peer-reviewed publication and a patent application. Its waveguide design has found application in two other Laboratory projects: a neodymium fiber amplifier around 1425 nm (also resulting in publication and patent application),9,10 and the eye-safer fiber laser project, which started this year.11

References

- Beach, R. J., et al., “Scalable antiguided ribbon laser.”JOSA B 19(7), 1521 (2002). UCRL-JC-142422.

- Ainslie, B. J., et al., “The fabrication, assessment and optical properties of high-concentration Nd3+- and Er3+-doped silica-based fibres.” Mater. Lett. 6(5), 139 (1998).

- Farries, M. C., P. R. Morkel, and J. E. Townsend, “Spectroscopic and lasing characteristics of samarium doped glass fibre.” IEEE J. OptoElectronics 137(5), 318 (1990).

- Pax, P., and J. Dawson, Sm-doped silica glass composition. Lawrence Livermore National Laboratory, Livermore, CA (2014). LLNL-MI-665068.

- Drachenberg, D., et al., “First multi-watt ribbon fiber oscillator in a high order mode.” Optic. Express 21(15), 18089 (2013).

- Pax, P. H., et al., “Scalable waveguide design for three-level operation in Neodymium doped fiber laser.” Optic. Express 24(25), 28633 (2016). LLNL-JRNL-70441.

- Dawson, J. W., et al., “Analysis of the scalability of diffraction-limited fiber lasers and amplifiers to high average power.” Optic. Express 16(17), 13240 (2008).

- Pax, P. H., et al., Waveguide design for line selection in fiber lasers and amplifiers. USPTO Patent Application 15/288,590 (2016). LLNL-IL-13058.

- Dawson, J. W., et al., “1.2 W laser amplification at 1427 nm on the 4F3/2 to 4I13/2 spectral line in an Nd3+ doped fused silica optical fiber.” Optic. Express 24(25), 29138 (2016). LLNL-JRNL-702161.

- Dawson, J. W., et al., Nd3+ fiber laser and amplifier. USPTO Patent Application 15/288,810 (2016). LLNL-IL-13120.

- Drachenberg, D., et al., Power scalable eye-safer laser systems for defense applications. Lawrence Livermore National Laboratory LDRD project 17-ERD-034 (2016).

Publications and Presentations

- Dawson, J. W., et al., "1.2W laser amplification at 1427nm on the 4F3/2 to 4I13/2 spectral line in an Nd3+ doped fused silica optical fiber." Optic. Express 24, 29138 (2016). LLNL-JRNL-702161.

- Pax, P., et al., "Scalable waveguide design for three-level operation in Neodymium doped fiber laser." Optic. Express 24, 28633 (2016). LLNL-JRNL-704410.