Sergei Kucheyev (16-FS-005)

Abstract

Planarization of low-density nanoporous solids is challenging. In this feasibility study, we demonstrate that medium-dose ion bombardment results in significant smoothing of silica aerogels, yielding mirror-like surfaces after metallization. The surface-smoothing efficiency scales with the electronic stopping power of energetic ions. Planarization is accompanied by subsurface monolith densification, leading to surface exfoliation at high ion doses. These findings have implications for the fabrication of graded-density nanofoams, aerogel-based lightweight optical components, and meso-origami.

Background and Research Objectives

Aerogels (AGs) represent a broad family of nanoporous materials with typical porosities greater than 80 percent. These materials have an open-cell structure of nanoligaments made of (curved) nanosheets, nanorods, or chains of interlinked nanoparticles. These nanoligaments are interconnected in a macroscopic three-dimensional porous assembly. Conventional sol-gel-derived nanoporous silica and carbon are prototypical AG materials. Current and potential applications of AGs include lightweight optical components, electrochemical devices, hydrogen storage, catalytic supports, compliant electrical contacts, energy absorbing structures, and laser targets for thermonuclear fusion and high-energy density physics research. Some of these applications call for monolithic (rather than powdered) AG parts with well-defined shapes and surface topography.

The net shaping of AGs is a challenge. Mold casting of AGs has limitations associated with possible mold geometries and issues with non-uniform foam shrinkage, the chemical compatibility of molds, demolding, and the formation of surface “skin” layers. The shaping of AGs by subtractive manufacturing techniques such as mechanical and laser machining has also proven to be difficult. Problems stem from the general incompatibility of AGs with liquids. Meniscus forces result in the collapse of AG pores on wetting and/or drying. Mechanical machining of AGs is further complicated by poorly understood fracture behavior of nanoporous solids, particularly in the low-density regime.

In this study, with an example of silica AGs, we demonstrate that medium-dose (1e15 – 1e16 cm-2) ion bombardment leads to a major reduction in surface roughness, yielding mirror-like surfaces after subsequent metallization. Our results reveal that the ion-beam smoothing efficiency is controlled by the electronic energy loss of ions rather than by ballistic sputtering and redeposition processes that are responsible for conventional ion-beam-induced planarization and shaping of full-density materials. Irradiation is also accompanied by sub-surface foam shrinkage that leads to surface layer exfoliation with increasing ion dose. These three interrelated phenomena (planarization, densification, and exfoliation) have technological implications for AG planarization, the fabrication of graded-density foams, rapid material removal via radiation-induced surface exfoliation, and AG-based meso-origami.

Scientific Approach and Accomplishments

The monolithic nanoporous silica AGs studied here were prepared by base-catalyzed hydrolysis of tetramethylorthosilicate. The AG density was 15 percent of the full-density silica. All experiments were performed on optically transparent fracture surfaces prepared by propagating cracks along straight scratches made on monolith surfaces. Before ion irradiation, monolithic AG pieces were attached to silicon wafers with epoxy.

The 4 MV ion accelerator (National Electrostatics Corporation, model 4UH) at Lawrence Livermore National Laboratory was used for ion irradiation. Sample surfaces were examined by scanning electron microscopy (SEM) in a JEOL 7401-F microscope operated at 2 kV and by tapping-mode atomic force microscopy (AFM) under ambient conditions with a Digital Instruments Dimension 3000 scanning probe microscope. The elastic modulus was measured by nanoindentation in an MTS XP Nanoindenter with a diamond Berkovich indenter in a load-control mode in laboratory air at room temperature.

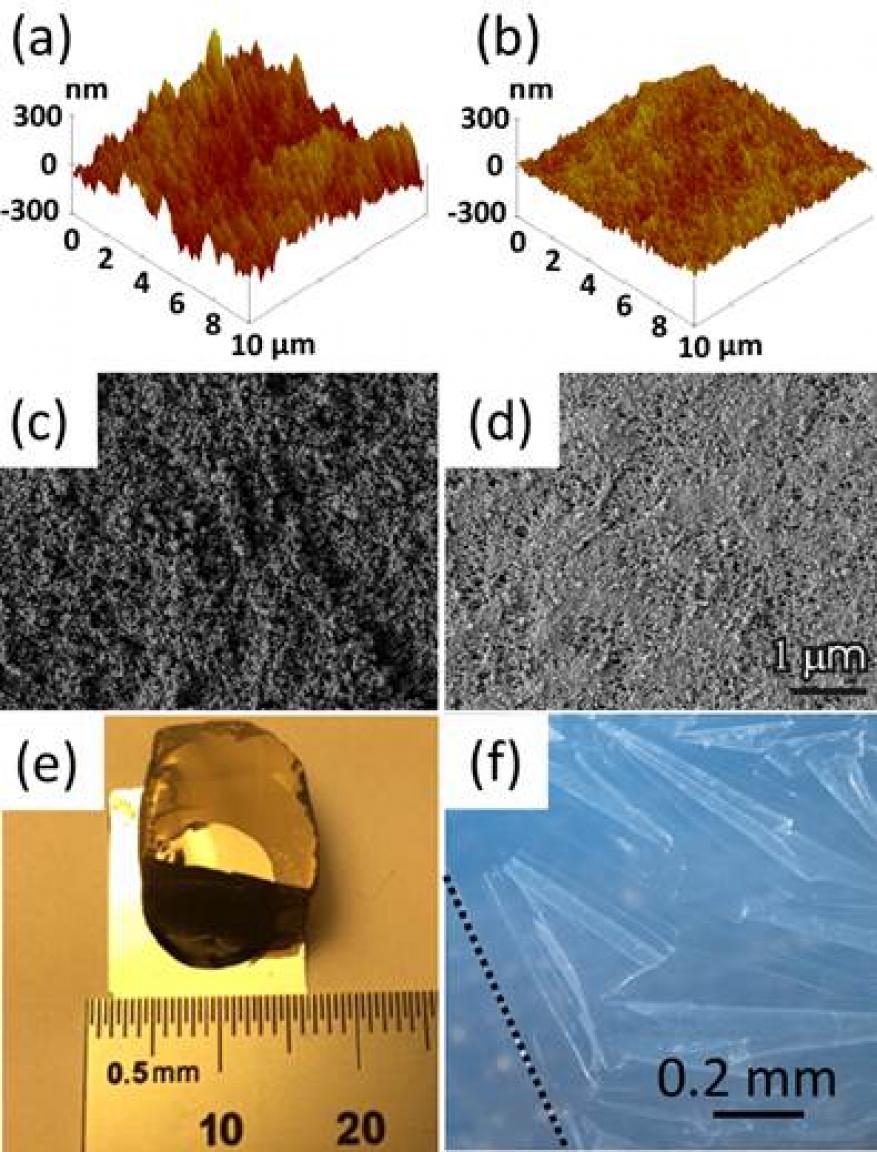

Figures 1a and 1b show AFM images (with the same vertical scale) of AG surfaces before and after bombardment with 3.8 MeV Ne ions. Ion-beam-induced smoothing is clearly evident from a comparison of these two images. Irradiation-induced changes in surface morphology are better illustrated in Figures 1c and 1d, showing plan-view SEM images of AG surfaces before and after bombardment with 3.8 MeV Ar ions. It is seen that ion bombardment results in the flattening of protrusions on the relatively rough fracture surface. The AG monolith after irradiation (Figure 1d exhibits a densified web-like surface “coating.” This web-like morphology is characteristic for all the irradiation conditions used in the present study. Cross-sectional SEM imaging of irradiated AG monoliths prepared by fracturing along planes perpendicular to sample surface did not reveal any detectable ion-beam-induced changes in nanofoam morphology or ligament shapes and sizes. Images of such fracture-made cross-sections exhibit ligament morphology, which is statistically indistinguishable from that shown in Figure 1c. Hence, the ion-beam-induced modification of AG ligament morphology is mostly limited to the monolith surface.

Figure 1e is an optical microscopy image of an AG sample that was bombarded with 3.8 MeV Xe ions through a circular mask. Ion irradiation was followed by sputter coating with a layer of Pt. Figure 1e clearly shows that the irradiated area exhibits a reflective (mirror-like) surface. In contrast, without prior ion bombardment, AG fracture surfaces sputter-coated with metals are poorly reflective. This is consistent with the challenges encountered in previous attempts to fabricate metal-coated AG-based lightweight reflectors from as-fractured AG surfaces.

We have observed such a phenomenon of radiation-induced surface smoothing for all the bombardment conditions from this study. What are the physical mechanisms of the ion-beam-induced planarization revealed by Figure 1? Is the planarization phenomenon caused by ballistic processes within collision cascades or intense electronic excitation along ion trajectories? To answer these questions, we have measured surface roughness of AGs bombarded under different conditions characterized by a broad range of nuclear and electronic energy loss in AG ligaments. Our data has revealed a close-to-linear dependence of surface roughness on electronic energy loss. Importantly, roughness does not scale with either nuclear energy loss or total (nuclear and electronic combined) losses, suggesting that intense electronic excitation around ion tracks is responsible for the ion-beam-induced planarization phenomenon. Such a radiation-induced planarization phenomenon could be attributed to slower energy dissipation at the sample surface where the ligaments terminating the surface are poorly interconnected as opposed to the ligaments in the AG bulk. Upon ion impact and associated intense electronic excitation, the local temperature of ligaments at the monolith surface increases, and they could experience energetically favorable coarsening leading to surface smoothing.

In addition to surface planarization, ion bombardment leads to AG densification, which has previously been reported for both silica and carbon AGs, and high-density nanoporous silica Vycor glass. We monitored radiation-induced foam densification by measuring elastic modulus (E), which is very sensitive to changes in the monolith density. Indeed, the E of the silica AGs such as studied here depends strongly super-linearly on the monolith density (with an exponent of approximately 5). Our results have revealed that E scales super-linearly with the electronic stopping power.

Radiation-induced densification of near-surface layers of AGs is inevitably accompanied by the development of mechanical stress. Figure 1(f) is an example of the phenomenon of stress-induced surface exfoliation that occurs when AGs are irradiated above certain threshold doses. The near-surface layer densified by ion irradiation fractures from the underlying AG monolith. The relaxation of in-built stress in the AG layer after exfoliation results in deformation, leading to the formation of three-dimensional nanoporous structures such as tubes or spirals (Figure 1f). We limited ourselves only to the demonstration of exfoliation. This interesting phenomenon deserves further systematic studies because it could be used for rapid material removal in AG machining. Moreover, with irradiation-assisted control of near-surface stresses in AGs, ion bombardment of AGs could be developed as a method somewhat similar to self-folding and/or rolling-up of patterned layers referred to as meso-origami.

Impact on Mission

We explored the feasibility of novel material modification methods and increasing flexibility of the fabrication of nanometer-scale porous materials; we also demonstrated a novel method of surface planarization of low-density aerogels. The development of a new technology for tuning properties of nanometer-scale foams will enable future high-energy-density physics and Inertial Confinement Fusion experiments that are not currently possible. As such, this feasibility study supports the Laboratory's core competencies in both advanced materials and manufacturing and high-energy-density science.

Conclusion

This study has demonstrated that high-energy ion bombardment can be used for planarization, densification, and exfoliation of low-density nanoporous aerogels. Radiation-induced changes in surface roughness and elastic modulus scale with electronic energy loss of energetic ions. These results could have important technological implications and warrant further systematic studies.

Publications and Presentations

Charnvanichborikarn, S., et al. 2016. "Noble Gas Retention in Nanoporous Carbons." 20th International Conference on Ion Beam Modification of Materials (IBMM-2016), Wellington, New Zealand, October 30–November 4, 2016. LLNL-POST-707165.

Kucheyev, S. O. and S. J. Shin. 2017. "Ion-Beam-Induced Planarization, Densification, and Exfoliation of Low-Density Nanoporous Silica." Applied Physics Letters 111, 133104. LLNL-JRNL-708784.

———. 2017. Planarization, Densification, and Exfoliation of Porous Materials by High-Energy Ion Beams, U.S. patent application 15/661,645, filed on July 27, 2017. IL Number: IL-13148.