Geoffrey Oxberry | 16-ERD-025

Overview

Additive manufacturing methods provide engineers with almost unlimited flexibility to design components. However, engineering intuition cannot comprehensively explore this large design space, so component design is currently the limiting step in additive manufacturing research. To remove this design bottleneck, we developed computational design software called Livermore Design Optimization (LiDO) for topology optimization, whereby the optimal layout of material for a part is determined in order to accomplish a given objective (e.g., stiffness) subject to design specifications (such as mass). LiDO interfaces with new algorithms that enable it to solve structural topology-optimization problems consisting of more than 800 million design variables while remaining general enough to accommodate stress constraints. These algorithms have been implemented in the new HiOp optimization library (Petra 2017). LiDO also incorporates two novel design parameterizations based on (1) Fourier series that do not require filtering and (2) the radii of rods in lattice unit cell structures that enable efficient multiscale material design. Using homogenization theory, finite element methods, and machine learning methods, LiDO computes the effective elasticity of a lattice cell as a function of rod radii so that finite element methods are not required to resolve each individual unit cell during design optimization. Finally, LiDO implements topology optimization under uncertainty using a novel two-level parallel approach: the first level of parallelism is over the finite element mesh, and the second level is over samples of uncertain parameters.

Results on uncertain loading demonstrate that designing for minimum average compliance over uncertain loads yields a better design than minimizing compliance for an average load. With these new design optimization capabilities, LiDO has the potential to transition to programmatic applications as a tool to improve Laboratory additive manufacturing capabilities in support of its scientific, defense, and weapons missions.

Background and Research Objectives

Additive manufacturing (AM) methods have enabled the manufacture of parts and materials with unprecedented control over geometry and composition. However, this new technology encompasses a large design space that cannot be explored fully using engineering intuition alone. In addition, designs for AM production must tolerate uncertainty in operating conditions (such as loading) and manufacturing variations (which result in material defects). As a result, a key limiting factor in advancing AM technology is the ability to generate new high-performance designs through more systematic means (National Research Council 2008).

Topology optimization generates novel designs for AM by computing the material layout of a part or metamaterial by solving an optimization problem formulated by providing a design parameterization, physics model, design specifications, and a quantity-of-interest to minimize (or maximize) as an objective (Bendsoe and Sigmund 2011). The following is an example of the information that is used in a topology-optimization computation:

- Objective: minimize compliance (see paragraph 2)

- Design parameterization: percentage of material in each cell of a finite element mesh

- Physics model: continuum mechanics, modeled using a finite element method

- linear elastic material

- elasticity depends on percentage of material in each cell

- Design specifications: on mass and on loads

- mass must be less than the given upper bounding number

- design is subject to one or more load cases

As shown in the example above, typical approaches to topology optimization use a design parameterization with a number of design variables that are proportional to the number of elements in a finite element mesh (Bendsoe and Sigmund 2011). To improve efficiency and reduce the time required to solve topology-optimization problems with large numbers of design parameters, we developed methods to generate alternative parameterizations that reduce the number of design parameters needed to represent families of possible designs.

At project inception, topology-optimization research (Kennedy 2015, Sigmund 2001, Liu and Tovar 2014, Andreassen et al. 2011) usually focused on solving problems with a moderate number of design parameters (four million or fewer) using single-physics models (typically structural or thermal physics). Optimization under uncertainty was limited to serial algorithms, which restricted the number of design scenarios used to approximate risk measures like averages, limiting accuracy (Schevenels et al. 2011, Wang et al. 2011, White et al. 2018, Lazarov et al. 2011 and 2012). Our original objective was to improve on this state-of-the-art by developing parallel topology-optimization algorithms for designing load-bearing electronic band-gap metamaterials subject to manufacturing uncertainty (e.g., defects). These designs would be novel because existing band-gap metamaterial designs are not load-bearing (Men et al. 2010, 2011, and 2014). As intermediate objectives, we needed to perform the following steps:

- develop topology-optimization software capable of solving the example problem shown above

- extend this software to model manufacturing uncertainty in structural physics

- extend this software to model designs with electromagnetic functionality

- design a negative index of refraction metamaterial without uncertainty

We accomplished the first intermediate objective (Arrighi et al. 2018), but none of the remaining objectives were accomplished due to changes in funding level and project scope. We determined that additional capability was needed to develop more efficient topology-optimization methods that could eventually solve our original problem. As a result, we performed the following steps instead:

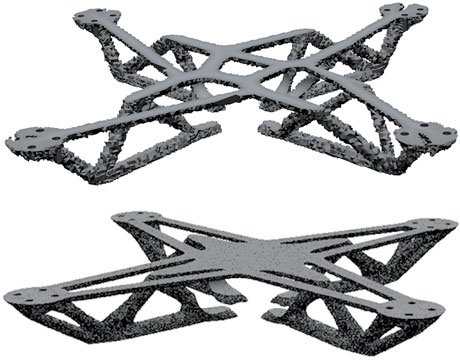

- developed new parallel, scalable, and general-purpose topology-optimization methods that solve topology optimization problems parameterized by 800+ million design variables (see figure)

- developed design representations using fewer variables to compute designs faster

- developed novel parallel algorithms to design parts under uncertain loads.

Impact on Mission

Our research advances the science, technology, and engineering competencies that are the foundation of the NNSA mission. Specifically, this research enhances the additive manufacturing capabilities at Lawrence Livermore National Laboratory by providing engineers with a computational tool that generates novel designs that perform better than engineering intuition alone. As such, this work supports Laboratory missions in weapons, science, and defense that already make use of additive manufacturing. It also supports the Laboratory’s core competencies in high-performance computing, simulation, and data science. Its likely impact on individual programs will be to provide an internal tool that integrates with existing Laboratory investments in AM and high-performance simulation for programmatic design applications and to incorporate quantitatively known uncertainties in operating conditions and manufacturing processes into the design process. This project has already brought in new staff and has contributed to starting up the Center for Design Optimization at the Laboratory. We expect to add new capabilities to LiDO, including designing with materials with nonlinear elastic behavior, multiphysics, and transient phenomena.

Conclusion

Moving forward, we are primarily transitioning this topology-optimization work to programmatic applications by positioning it as a tool to improve current design processes. The Laboratory's Center for Design Optimization currently collaborates with Autodesk to interface LiDO with Autodesk level-set-based design approaches. We anticipate a potential transfer of LiDO technology to industry as the software and optimization methods mature. The Laboratory also received a DARPA grant with collaborators at UT-Austin and UC-Berkeley on design optimization two years ago, so we believe there is potential funding for future work from DOD- and DHS-related sources, as well as future academic collaborations.

References

Andreassen, E., et al. 2011. "Efficient Topology Optimization in MATLAB Using 88 Lines of Code." Structural and Multidisciplinary Optimization 43(1):1–16. doi: 10.1007/s00158-010-0594-7.

Arrighi, W. J., et al. 2018. LiDO: Livermore Design Optimization . Lawrence Livermore National Laboratory, Livermore, CA. LLNL-CODE-728517.

Bendsoe, M. P. and O. Sigmund. 2004. Topology Optimization: Theory, Methods, and Applications, 2e. Springer-Verlag, Berlin. doi: 10.1007/978-3-662-05086-6.

Kennedy, G. 2015. "Large-Scale Multi-Material Topology Optimization for Additive Manufacturing." 56th American Institute of Aeronautics and Astronautics Structures, Structural Dynamics, and Materials Conference, AIAA SciTech Forum (AIAA 2015-1799):1–13. January 2015. doi: 10.2514/6.2015-1799.

Lazarov, B. S., et al. 2011. "Robust Design of Large-Displacement Compliant Mechanisms." Mechanical Sciences 2(2):175–182. doi: 10.5194/ms-2-175-2011.

——— . 2012. "Topology Optimization with Geometric Uncertainties by Perturbation Techniques." International Journal for Numerical Methods in Engineering 90(11):1321–1336. doi: 10.1002/nme.3361.

Liu, K. and A. Tovar. 2014. "An Efficient 3D Topology Optimization Code Written in Matlab." Structural and Multidisciplinary Optimization 50(6):1175–1196. doi: 10.1007/s00158-014-1107-x.

Men, H., et al. 2010. "Bandgap Optimization of Two-Dimensional Photonic Crystals Using Semidefinite Programming and Subspace Methods." Journal of Computational Physics 229(10): 3706–3725. doi: 10.1016/j.jcp.2010.01.023.

——— . 2011. "Design of Photonic Crystals with Multiple and Combined Band Gaps." Physical Review E 83(4). doi: 10.1103/PhysRevE.83.046703.

——— . 2014. "Robust Topology Optimization of Three-Dimensional Photonic-Crystal Band-Gap Structures." Optics Express 22(19): 22632. doi: 10.1364/OE.22.022632.

National Research Council. 2008. "Integrated Computational Materials Engineering: A Transformational Discipline for Improved Competitiveness and National Security." Washington, D.C., The National Academies Press. doi: 10.17226/12199.

Petra, C. G. 2017. "A Memory-Distributed Quasi-Newton Solver for Nonlinear Programming Problems with a Small Number of General Constraints." Manuscript in preparation.

Schevenels, M., et al. 2011. "Robust Topology Optimization Accounting for Spatially Varying Manufacturing Errors." Computer Methods in Applied Mechanics and Engineering 200(49-52):3613–3627. doi: 10.1016/j.cma.2011.08.006.

Sigmund, O. 2001. "A 99 Line Topology Optimization Code Written in Matlab." Structural and Multidisciplinary Optimization 21(2):120–127. doi: 10.1007/s001580050176.

Wang, F., et al. 2011. "On Projection Methods, Convergence and Robust Formulations in Topology Optimization." Structural and Multidisciplinary Optimization 43(6):767–784. doi: 10.1007/s00158-010-0602-y.

White, D.A., et al. 2018. "Topological Optimization of Structures Using Fourier Representations." Structural and Multidisciplinary Optimization 58(3):1205–1220. doi: 10.1007/s00158-018-1962-y.

Publications and Presentations

Arrighi, W. J., et al. 2018. LiDO: Livermore Design Optimization . Lawrence Livermore National Laboratory, Livermore, CA. LLNL-CODE-728517.

Cosmin, P. 2017. High-Performance Optimization Solver (HiOP). Lawrence Livermore National Laboratory, Livermore, CA. LLNL-CODE-742473.

Oxberry, G. M. 2016. Google Test MPI Listener. Lawrence Livermore National Laboratory, Livermore, CA. LLNL-CODE-739313.

Oxberry, G. M., et al. 2017. "Topology Optimization Using Conditional Value-at-Risk." Modeling and Optimization: Theory and Applications (MOPTA), Bethlehem, PA, August 2017. LLNL-PRES-739820.

——— . 2017. "On Applying Effective Parallelization of Nonlinear Programming to Topology Optimization." SIAM Conference on Computational Science and Engineering, Atlanta, GA, February 2017. LLNL-POST-725198.

——— . 2018. "Computational Design Optimization Under Uncertainty." 4th Cross-AM JOWOG Joint Working Group Meeting, Lawrence Livermore National Laboratory, February 2018. LLNL-PRES-760617.

Petra, C. G., et al. 2018. "A Structured Quasi-Newton Algorithm for Optimizing with Incomplete Hessian Information." Optimization Online 25. LLNL-JRNL-745068.

White, D. A. 2017. "Topological Optimization in Fourier Space." 12th World Congress on Structural and Multidisciplinary Optimization (WCSMO17), Braunschweig, Germany, June 2017. LLNL-PRES-731031.

White, D. A. and A. Voronin. 2018. "A Computational Study of Symmetry and Well-Posedness of Structural Topology Optimization." Structural and Multidisciplinary Optimization . doi: 10.1007/s00158-018-2098-9. LLNL-JRNL-761457.

White, D. A., et al. 2018. "Topological Optimization of Structures Using Fourier Representations." Structural and Multidisciplinary Optimization 58(3): 1205–1220. doi: 10.1007/s00158-018-1962-y. LLNL-JRNL-736779.