Matthew McNenly | 16-ERD-003

Overview

Current fuel-testing methods for internal-combustion engines require large sample volumes. The American Society for Testing and Materials standards to measure the U.S. anti-knock index for the sale of gasoline typically requires a 1-L sample. This restricts testing of new fuel blends for which liter-scale production is costly. Millimeter-scale flow reactors are a promising alternative to generate data quickly and inexpensively with small sample volumes (less than 1 mL). This data could accelerate new fuel discovery if the measured quantities are correlated to engine-performance metrics like ignition quality.

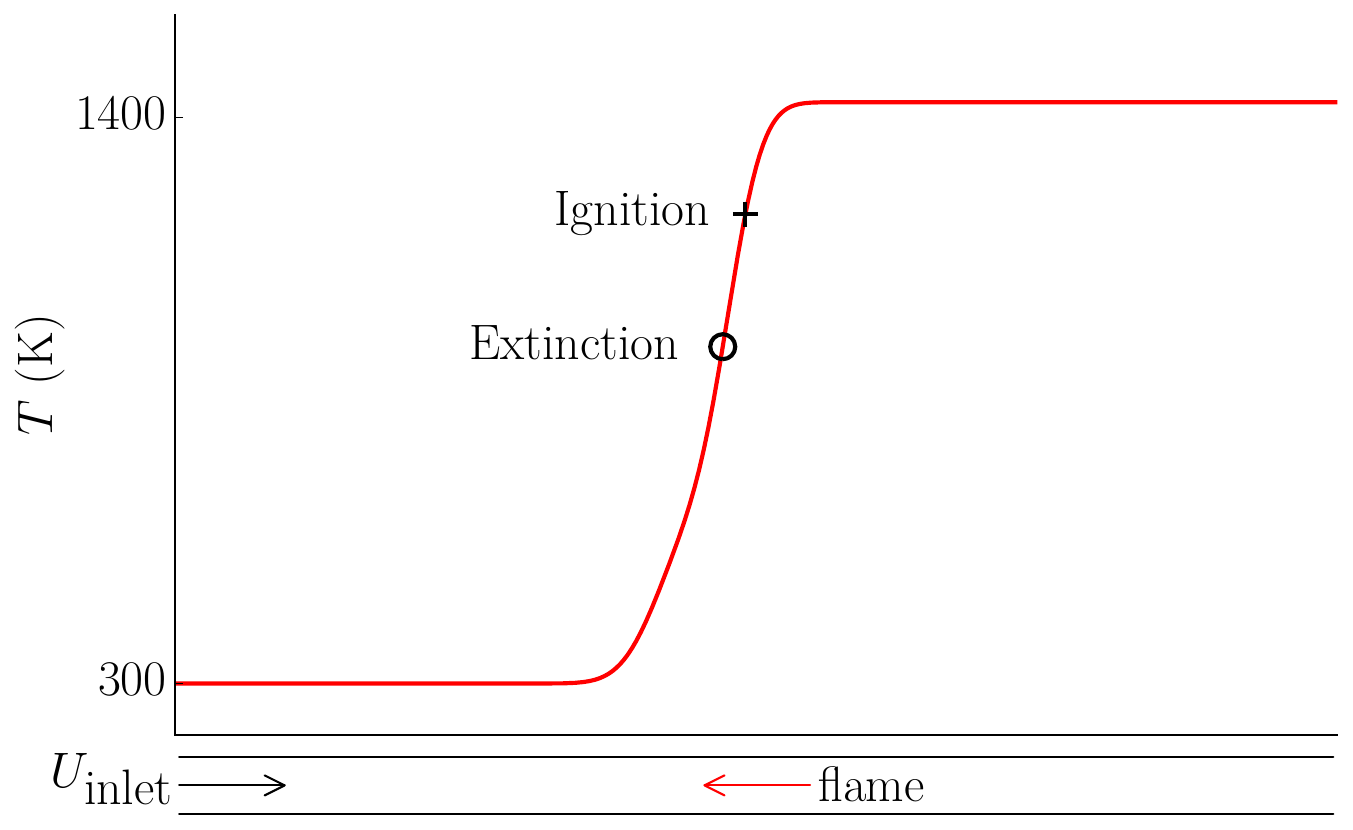

In this research, combustion in a narrow channel with an imposed temperature profile was studied through numerical simulations to determine its potential as a micro-liter fuel-ignition tester (micro-FIT). A computationally efficient simulation methodology for unsteady laminar flames was developed and validated. Simulations of the micro-FIT at engine pressures show a significant influence of low-temperature chemistry, as is the case in real engines. Different transportation fuels were simulated and found to have different ignition and extinction locations in the micro channel. These results show the potential of the micro-FIT to distinguish between engine-relevant fuels. Further, simulated micro-FIT data were used to infer a reduced chemical model for a practical fuel. This inferred chemical model was found to be in good agreement with other chemical models in the literature, providing evidence that future experimental micro-FIT results could be used to provide chemistry information for previously uncharacterized fuels. Finally, a link between the micro-FIT simulation data and an engine-relevant performance metric, the octane number, was established. A neural network was trained using experimental octane-number measurements and simulated micro-FIT data. The micro-FIT–informed neural network predicted the octane number of practical fuel blends with good accuracy; specifically, it demonstrated a prediction error less than half that of an alternative small-sample-volume approach using nuclear magnetic-resonance spectroscopy. All these results yield a path for micro-FIT to screen new fuels using small samples and predict their performance in an engine.

Background and Research Objectives

An 85-year gap separates fuel certification and modern automotive engines. The engine configuration used for fuel testing is very far removed from the operating conditions of modern production engines, which use high compression ratios, turbochargers, and direct fuel injection. These standard fuel measurements have even less connection with many proposed clean-engine concepts that use chemistry-controlled combustion, such as those researched under the DOE Vehicle Technology Office. Worse, these tests typically require at least 1 L of fuel. Large test volumes make it impossible to test cutting-edge, bio-derived fuels and additives that have not been scaled beyond a benchtop reactor. Thus, a critical need exists to predict new fuel performance with a sample of less than 1 mL.

Millimeter-scale flow reactors are a promising alternative to generate data quickly and inexpensively with small sample volumes, which could accelerate new fuel discovery if correlated to ignition-quality metrics. This project addressed key gaps in the fundamental understanding needed to link flame dynamics at the millimeter scale to engine performance. The objectives of this project were to (1) develop a predictive simulation methodology of a micro-FIT; (2) show that micro-FIT can be used to distinguish transportation fuels at engine conditions; (3) use micro-FIT to infer the chemistry of transportation fuels; and (4) develop a link between micro-FIT and engine-performance metrics such as the octane number.

The scientific approach is based on the numerical simulation of the micro-FIT system. The flow configuration used for all simulations is illustrated in the figure below.

Impact on Mission

This project provided scientific proof of the efficacy of small-volume fuel testing, which should serve as a key enabler for the future co-optimization of fuels and engines. This supports the Laboratory's energy- and climate-security mission-focus area and the DOE's goals in science and energy, especially strengthening the connection between advances in fundamental science and technological innovation. Co-optimization will enable greater energy and climate security by reducing petroleum consumption. The research methodology developed for fuel-performance simulation and design is also relevant to the Laboratory's core competency in high-performance computing, simulation, and data science, and should attract considerable collaboration and interest from the energy sector.

Conclusion

The results of this research confirmed the potential of micro-FIT to screen new fuels using small samples and predict their performance in an engine. A key path forward is the design of the next-generation micro-flow reactor for testing in partnership with traditional and bio-derived fuel providers. The simulations performed in the present study produced information necessary to design the experimental facility. These data include operating pressure, channel diameter and length, wall-temperature profile, mass flow rate, and fuel dilution levels to maximize measurement sensitivity for engine-relevant fuels. Using the methods pioneered in the present study, the experimental micro-FIT could be used to predict the engine performance of uncharacterized fuels. DOE funding through the Co-Optima program has been awarded to Louisiana State University to demonstrate a high-pressure millimeter flow reactor similar to micro-FIT.

Publications and Presentations

Druzgalski, C. L., et al. 2017. "Quantifying Reaction Rates Sensitivity and Discoverability in a Millimeter-Scale Flow Reactor." 10th International Conference on Chemical Kinetics, Chicago, IL, May 2017. LLNL-PRES-731701.

Lapointe, S., et al. 2017. "Simulations of a Micro-Liter Fuel Ignition Tester." 10th U.S. National Combustion Meeting, College Park, MD, April 2017. LLNL-PRES-730162, LLNL-CONF-725138.

——— . 2018. "Inferring Chemistry of Transportation Fuels at Engine-Relevant Conditions Using Simulations of a Micro-Liter Fuel Ignition Tester" (poster). LLNL-POST-747937.

——— . 2018. "Numerical Study of a Micro Flow Reactor at Engine Pressures: Flames with Repetitive Extinction and Ignition and Simulations with a Reduced Chemical Model." Combustion and Flame 197 102–110. doi: 10.1016/j.combustflame.2018.07.020. LLNL-JRNL-749373.

——— . 2018. "Reduced Chemical Model for Low and High-Temperature Oxidation of Fuel Blends Relevant to Internal Combustion Engines." Proceedings of the Combustion Institute , July 2018. doi: 10.1016/j.proci.2018.06.139. LLNL-JRNL-742185.

——— . 2018. "Simulations of a Micro-Liter Fuel Ignition Tester" (poster). LLNL-POST-732499.