Manyalibo Matthews (14-ERD-098)

Abstract

Particulate contamination negatively impacts a wide range of high-performance materials and devices, including microelectronics, space optics, lasers, and nuclear reactors. Such contamination is especially problematic in high-photon-flux lasers. This problem calls for improved optical designs with contamination-mitigation strategies for high-power laser systems. We will study the morphological and chemical evolution of surface-bound microscopic-scale particles in the presence of high-power laser light and those particles' interaction with an underlying optical surface to better understand laser–particle material interactions over temporal scales of pulsed-to-continuous waves. To this end, we are planning to (1) develop a suitable test chamber and diagnostic suite; (2) conduct experiments with different particle–surface pairs, chemical environments, and laser conditions; (3) simulate laser absorption, material response, and subsequent effects on laser beam propagation; and (4) explore mitigation strategies, including pre-pulse laser cleaning, chemical passivation, and coatings. Our primary focus will be on mirrors and windows in diode-pumped alkali lasers and high-power laser systems related to ignition fusion energy.

We expect to develop a functioning test bench that can be used to examine particle-driven damage events in situ and under a wide variety of conditions. We will also establish a computational capability that allows accurate simulation of laser and particle interactions at high laser powers. In addition, we will generate findings addressing the propensity for damage from specific particulate contamination in optics used in both high-power, continuous-wavelength lasers and high-energy, pulsed-power lasers. Finally, we will deliver an effective scheme for using coatings or vapor chemistry treatments to limit both local and nonlocal damage (that is, damage generated by phase objects).

Mission Relevance

This project enhances the performance of high-power laser systems in support of the Laboratory's core competency in lasers and optical science and technology and can extend our understanding of the effects of contamination on light propagation in the large, high-performance optics used in cyber security, space, and intelligence applications. Our research on thermal transport in laser-heated metal on surfaces can also advance laser-based additive manufacturing technologies for stockpile stewardship applications and supports the core competency of advanced materials and manufacturing.

FY15 Accomplishments and Results

In FY15 we (1) developed a model for ablation-driven phase object diffraction; (2) measured time-resolved plasma emission from individual, microscopic-particle contaminants under pulsed laser irradiation, characterizing plasma temperature and electron density associated with contaminant ablation (as part of a summer student project); and (3) conducted extensive damage probability studies on glass versus metal contaminants on fused silica and dielectric coatings, enhancing our understanding of material and morphological dependencies on subsequent damage.

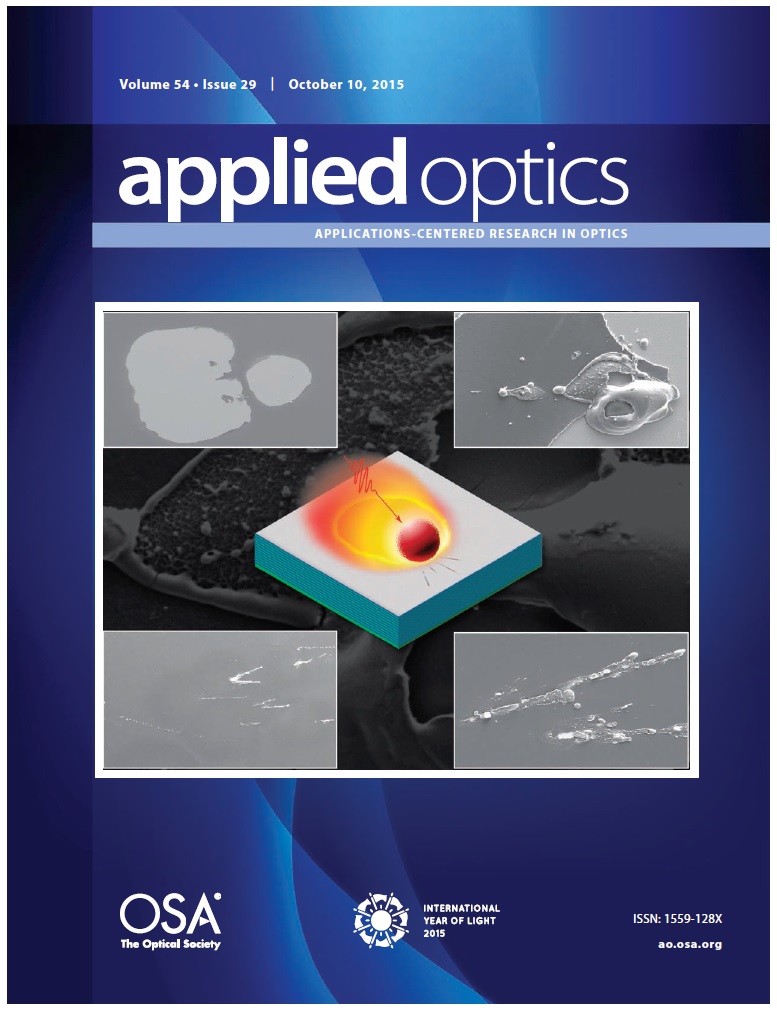

Montage of scanning electron microscopy images and schematic describing the effect of 1064-nm laser pulses on surface-bound metal contaminants for multiple-layer dielectric coatings.

Publications and Presentations

- Demos, S. G., et al., “Relaxation dynamics of nanosecond laser superheated material inside the surface of dielectrics.” Optical 2(8), 765 (2015). LLNL-JRNL-659895.

- Feigenbaum, E., S. Elhadj, and M. J. Matthews, “Light scattering from laser induced pit ensembles on high power laser optics.” Optic. Exp. 23, 10589 (2015). LLNL-JRNL-668127.

- Feigenbaum, E., N. Nielsen, and M. J. Matthews, “Measurement of optical scattered power from laser-induced shallow pits on silica.” Appl. Optic. 54, 8554 (2015). LLNL-JRNL-673988.

- Matthews, M. J., et al., “Micro-shaping, polishing, and damage repair of fused silica surfaces using focused infrared laser beams.” Adv. Eng. Mater. 17, 247 (2015). LLNL-JRNL-654070. http://dx.doi.org/10.1002/adem.201400349

- Qiu, S. R., et al., “Impact of laser-contaminant interaction on the performance of the protective capping layer of 1 ω high reflective mirror coatings.” Appl. Optic. 54, 8607 (2015). LLNL-JRNL-673678.