Kerry Krauter (15-FS-013)

Abstract

Diffraction gratings, similar to a lens or a mirror superimposed with a precise pattern of microscopic periodic structures, are used in optical elements of portable field sensors that spectrally characterize materials. Materials reflect, scatter, absorb, and emit electromagnetic radiation in ways characteristic of their molecular composition and macroscopic scale and shape. If radiation from a material is measured at many wavelengths, over a sufficiently broad spectral band, the resulting spectral signature, or simply spectrum, can be used to identify and discriminate among different classes of materials. "Hyperspectral" sensors employ hundreds of contiguous bands to identify a variety of natural and man-made materials. In this feasibility study, three advanced manufacturing techniques were considered as candidates to provide high-spectral-resolution diffraction gratings for discrimination of spectrum over a broad wavelength range of 0.35 to 15 μm. These three manufacturing techniques included: a design extension for Livermore-developed micro-mirrors to diffraction gratings, variable pitch-angle gray-scale lithography, and a metallic thin-film wrinkling technique. Of these techniques, gray-scale lithography and wrinkled thin films were determined to be feasible approaches to produce a diffraction grating. While we determined that gray-scale lithography is a viable option to produce a diffraction grating, the technique will require significant development to develop an etch recipe for materials beyond silicon. We extended our study into wrinkled thin films, which are low cost and showed particular promise, exploring groove shapes beyond sinusoids. We also identified two drawbacks of the thin-film wrinkling technique: poor grating performance because of practical limitations determined by fabrication process steps, and a fundamental limitation on the feasible groove shape, which is determined by the physics of the wrinkling phenomenon. As a result of our work, we have been able to partly overcome these limitations and have successfully fabricated shape-tunable wrinkled gratings with improved performance.

Background and Research Objectives

Current state-of the-art ground-based sensors are 1,000 lb and unable to access all areas of interest in the field because of their large size. Often, multiple sensors are required to perform a complete characterization because each sensor is based upon a grating that can only discriminate over a specific, fixed portion of the spectrum of interest. Current gratings are solid components, unable to change their angle or pitch to alter the spectral resolution provided to the user. Some manufacturers vary the groove spacing across a solid grating to support multiple wavelengths, but such gratings suffer performance issues because of difficulties in machining them. Our project focused on possible techniques for producing advanced manufactured gratings that had the potential to provide a new tool for sensor designers to obtain coverage of the entire spectrum of interest using a single grating. The three advanced manufacturing techniques we chose to explore were (1) an extension of the Livermore-developed micro-mirrors, (2) a metallic thin-film wrinkling technique, and (3) variable pitch-angle grey-scale lithography.

The current state-of-the-art technique is to utilize diamond flywheel cutting of the grooves into an optical substrate. This process is capable of producing exquisite quality gratings but is laborious and requires demanding precision control of the diamond flywheel. Advanced manufacturing techniques may ease some of the precision requirements while potentially allowing continuous adjustment of the blaze angle or pitch of the grating in situ, providing a new tool for the optical designer. (Groove spacing and blaze angle are the parameters typically used to meet grating performance requirements.) The thin-film wrinkling technique would allow for in situ adjustment of the pitch of the grating. Gray-scale lithography would allow variation in both the pitch and blaze angle without in situ adjustment. Our objective was to examine each advanced manufacturing method and to determine the feasibility of producing a viable diffraction grating.

In FY15 we studied the three techniques and evaluated the feasibility of each for producing a diffraction grating. We found that the micro-mirror technique was not capable of creating the mirror facet with the thin rectangular structure required to simulate a grating groove, nor did it have the fine control of the facet needed to angularly sweep over a range of blaze angles.1 Gray-scale lithography showed promise, although etching materials other than silicon must be developed. We partnered with AMFitzgerald of Burlingame, California, which has experts in advanced manufacturing, to evaluate gray-scale lithography and related techniques for our purpose.2 This technique is quite promising but will require etching recipe research and development to extend the technique to materials beyond silicon—tasks beyond the scope of our study. The third technique, gold-coated wrinkled thin films, proved feasible. We were able to fabricate several gold-coated diffraction gratings based on wrinkled thin films for simple performance testing. These studies were the focus of our FY16 efforts.

In the past, wrinkling-based processes have been successfully used to fabricate well-ordered, nonuniform sinusoidal patterns.3,4 Several studies have also demonstrated the dispersive behavior of such patterns.5,6 However, these studies were inadequate for determining the suitability of wrinkled patterns as high-performance diffraction gratings, primarily because of a lack of knowledge about (1) the feasible range of grating spacing and depth, (2) geometric defects in the wrinkled pattern that affect the diffracted beam quality, and (3) factors that limit the maximum achievable efficiency of a wrinkled grating. In our project, we quantified the feasible range of grating geometric parameters based on both theoretical and practical constraints and measured the diffraction angles of incident laser beams, enabling us to quantify the accessible design space for the tunable dispersive behavior of wrinkled gratings and to qualitatively estimate the deviation of this behavior from the expected value. Specifically, we determined (1) the design space for sinusoidal grooves is limited with a spacing of 600 nm to 50 μm and a maximum slope of 35°, (2) groove spacing can be tuned by 30% and the grating depth can be tuned by 100% via stretching, and (3) thin-film wrinkled groove shapes are not limited to sinusoidal grooves.

For FY16, our goal was to follow up on our FY15 results using wrinkled thin films to produce a diffraction grating. Our objective was to confirm the feasibility of fabricating a non-sinusoidal blazed grating using wrinkled thin films.

Scientific Approach and Accomplishments

To quantify the feasible design space available to thin-film wrinkled gratings, we combined analytical models that are available in the literature for wrinkled films with experimental data to determine the practical design limits.4 In our experiments to understand the optical quality of the gratings, the tested wrinkled patterns differed in terms of the fabrication process, reflective material coating, and amount of stretching.

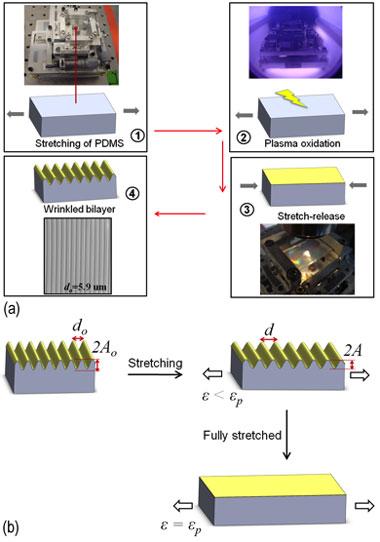

Physical wrinkled patterns were available as a work product from the Ph.D. thesis of one of our recently recruited postdoctoral reserachers.7 The fabrication process is summarized in Figure 1.

One-dimensional sinusoidal wrinkled patterns can be fabricated by compressing bilayers that comprise a stiff thin film supported on top of a compliant base. For example, wrinkles can be generated by first exposing a prestretched polydimethylsiloxane elastomer base to air plasma and then releasing the prestretch in the base. Polydimethylsiloxane belongs to a group of polymeric organosilicon compounds commonly referred to as silicones, and is known for its unusual flow properties and is optically clear. Exposing polydimethylsiloxane to air plasma generates a glassy film on top of the material. Instead of plasma exposure, metallic or polymeric thin films may be vapor deposited on top of the stretched elastomer to generate bilayers.

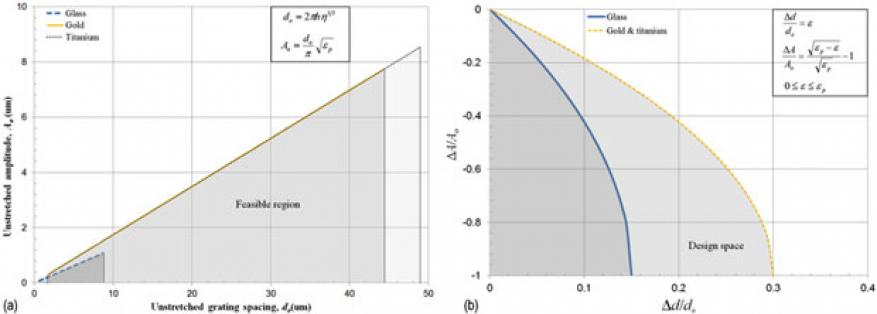

Supported thin films buckle to form wrinkles because releasing the pre-stretch in the base generates a compressive strain in the film. The periodic spacing of wrinkles is determined by the competition between the deformation energy in the base versus in the film, whereas amplitude is determined by the strain. Thus, the periodic spacing (do) and the amplitude (Ao) of the wrinkles can be tuned by controlling the thin film thickness (h), the ratio of the elastic moduli of the film and the base (η), and the fabrication prestretch (εp). The feasible design space for wrinkled patterns is determined by the feasible combination of these control parameters. This feasible region is illustrated in Figure 2(a) and is based on the feasible range of the control parameters listed in Table 1.

Table 1. Feasible range of operating parameters.

| Thin film material | Film thickness (h) | Elastic moduli ratio (η) | Maximum fabrication pre-stretch (εp) |

| Glass | 10–100 nm | 0.8 × 103 | 15% |

| Gold | 10–250 nm | 22.5 × 103 | 30% |

| Titanium | 10–250 nm | 30.2 × 103 | 30% |

During operation as a diffraction grating, the periodic spacing and amplitude of wrinkles can be tuned by stretching the bilayer, as shown in Figure 2(b). A reflective surface is created by depositing a thin layer of gold on top of the wrinkled surface. The degree of tunability of a wrinkled grating is determined by the fabrication prestretch, as summarized in Figure 2(b).

The initial set of gratings had several cracks perpendicular to the grooves which significantly degraded the beam quality. While clearly these first attempts were far from research-grade gratings, we were optimistic. A high density of surface cracks is expected when the polydimethylsiloxane surface is oxidized and glass-like. Techniques to avoid this have been demonstrated, and our FY16 work leveraged those techniques to improve the beam quality.

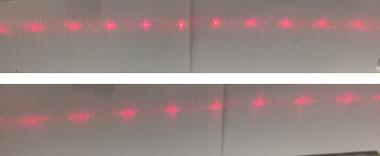

During FY15, we observed that the performance of wrinkled gratings was adversely affected by cracks perpendicular to the grooves to the point that the adjacent diffraction modes could not be distinguished. These cracks arise because of the mismatch in the Poisson’s ratio between the top and the bottom layers of the wrinkles. To reduce the crack density, one must carefully select the top layer so that the Poisson’s ratio is closer to that of the elastomeric polydimethylsiloxane base (Poisson’s ratio of 0.5). During FY16, we modified our process steps so that the top layer was a gold film (Poisson’s ratio of 0.42) instead of the glassy film (Poisson’s ratio of 0.17). This process modification improved the overall grating performance such that adjacent modes can now be distinctly identified in the diffraction pattern (Figure 3).

A successful process modification from glassy films to gold films required replacing the bearings in the tensile stretch stage with sealed bearings compatible with a high-vacuum metal deposition environment and incorporating an adhesion layer (titanium, 3.5- to 5-nm thick) between the gold film and elastomeric base. In the absence of the adhesion layer, no cracks were generated. However, the gold film delaminated during stretch release to generate an uncontrolled pattern instead of the deterministic periodic wrinkles. To fully eliminate cracks, one must be able to control the biaxial strains in the film. We were unable to explore the biaxial strain control technique in this project because of the significant resource requirements for designing and testing a two-dimensional tensile stage. Nevertheless, this is a promising avenue for future process development to further improve the grating efficiency.

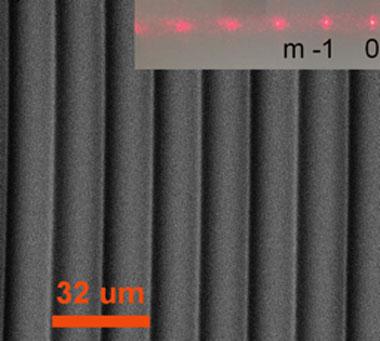

A review of the technical literature suggests that the wrinkling technique is fundamentally limited to fabrication of sinusoidal grooves. Thus, this technique would be of limited practical import because of its inability to fabricate non-sinusoidal “blazed” gratings. During FY16, we overcame this shape limitation by demonstrating the design and fabrication of asymmetric groove profiles (Figure 4) and by computationally demonstrating the ability to tune the shape of the grooves via stretch. We achieved this through our invention of a fabrication process scheme that deterministically introduces asymmetry in the film geometry.8 Upon release of the pre-stretch, this asymmetry in the film geometry generates non-sinusoidal asymmetric wrinkled grooves.

Accomplishments

As a result of this work we accomplished the following: (1) invention and demonstration of a new fabrication technique that overcomes the fundamental groove-shape based limitation of wrinkled structures, (2) a record of invention for the new thin-film wrinkled technique, (3) fabrication of shape-tunable non-sinusoidal blazed gratings using wrinkled thin films, and (4) qualitative verification of improved grating performance over previous attempts.

Impact on Mission

Advances in diffraction grating technology will benefit ground-based sensors with applications in intelligence and monitoring. In addition, there is a need within the intelligence community for a compact, broad-wavelength-range hyperspectral sensor. Current state-of the-art ground-based sensors are heavy and too large to maneuver into tight spaces of interest. Current sensors are also incapable of making measurements over wide wavelength ranges on a single line of sight. New techniques to create improved diffraction gratings for greater range and to allow for more compact sensors benefits the Laboratory's strategic focus area in cyber security, space, and intelligence. Improved manufacturing techniques likewise support the core competency in advanced materials and manufacturing.

Conclusion

This feasibility study identified two potential advanced manufacturing techniques to produce a diffraction grating: gray-scale lithography and wrinkled thin films. We used modeling and information from potential industrial partners to determine that it should be feasible to produce a useful diffraction grating using gray-scale lithography. Our study also confirmed the viability of a wrinkled thin-film grating and reduced further development risk by demonstrating diffraction grating based upon wrinkled thin films and qualitatively evaluate those gratings with a single-wavelength laboratory setup. Our demonstration of a blazed thin-film grating suggests that with further work, this technique may produce a quality grating capable of in situ adjustment in both groove spacing and groove angle. This feasibility study expanded the expertise of LLNL’s staff in advanced materials and manufacturing for optical applications by successfully identifying external partners for capital intensive manufacturing (gray-scale lithography), and leveraging the skills of a recently hired postdoctoral researcher to invent and develop a low-cost, on-site manufacturing capability for thin-film wrinkling. This expanded advanced manufacturing capability enables the possible design of measurement systems based upon a diffraction grating capable of providing varying spectral resolution with the same line of sight.

References

- Hopkins, J. B., R. M. Panas, and Y. Song, “Categorization and review of existing micro-mirror array technologies,” Proc. Ann. Mtg. American Society for Precision Engineering 30th Ann. Mtg., Austin, TX, Nov. 1–6, 2015. LLNL-CONF-676358.

- Chung, C., LLNL Greyscale for variable blazed gratings. (2015).

- Bowden, N., et al., "Spontaneous formation of ordered structures in thin films of metals supported on an elastomeric polymer." Nature 393(6681), 146 (1998). http://dx.doi.org/10.1038/30193

- Saha, S. K., and M. L. Culpepper, "Design of a compact biaxial tensile stage for fabrication and tuning of complex micro- and nano-scale wrinkle patterns." J. Micro Nano-Manuf. 3(4), 041004 (2015). http://dx.doi.org/10.1115/1.4031382

- Harrison, C., et al., "Sinusoidal phase grating created by a tunably buckled surface." Appl. Phys. Lett. 85(18), 4016 (2004). http://dx.doi.org/10.1063/1.1809281

- Yu, C., et al., "Tunable optical gratings based on buckled nanoscale thin films on transparent elastomeric substrates." Appl. Phys. Lett., 96(4), 041111 (2010). http://dx.doi.org/10.1063/1.3298744

- Saha, S. K., Predictive design and fabrication of complex micro and nano patterns via wrinkling for scalable and affordable manufacturing. Ph.D. Thesis, Massachusetts Institute of Technology, (2014). http://hdl.handle.net/1721.1/93860

- Saha, S. K., K. G. Krauter, and R. M. Panas, Template-free fabrication of shape-tunable flexible diffraction gratings, Lawrence Livermore National Laboratory Record of Invention IL-13070 (2016).

Publications and Presentations

- Hopkins, J. B., R. M. Panas, and Y. Song, “Categorization and review of existing micro-mirror array technologies,” Proc. Ann. Mtg. American Society for Precision Engineering 30th Ann. Mtg., Austin, TX, Nov. 1–6, 2015. LLNL-CONF-676358.

- Saha, S. K., K. G. Krauter, and R. M. Panas, Template-free fabrication of shape-tunable flexible diffraction gratings, Lawrence Livermore National Laboratory Record of Invention IL-13070 (2016).