Jeffrey Bude (16-ERD-016)

Project Description

Pulsed-laser material modification can lead to material and component failure in advanced laser systems or sensitive defense-related systems. Laser systems for scientific applications and national security missions are often designed to operate under conditions of extreme optical intensity, high average power, or flux density. This can result in degradation and damage to key optical components, limiting system performance and imposing severe constraints on operation. General modes of damage are related to how different materials absorb energy and how they respond to this energy deposition. For laser-based machining, these damage modes affect throughput, collateral damage, and precision. In this research project, we will integrate laser material testing, advanced diagnostics, characterization, and simulation to develop a more rigorous theoretical and experimental understanding of pulsed-laser processes in dielectrics, semiconductors, metals, and ion-doped glasses relevant to damage, material failure, ablation physics, and pulsed-laser machining.

We expect to develop a theoretical and experimental understanding of the mechanisms of ablation, material damage, and failure for optical materials, semiconductors, and metals. General modes of damage are related to how different materials absorb energy and how they respond to this energy deposition. These same issues drive optimization and extension of laser-based material processing, and affect laser-based machining. We intend to (1) determine how material properties affect damage, (2) identify wavelength-dependent mechanisms for surface damage, (3) develop models of short-pulse (<10 ps) ablation and laser machining, (4) demonstrate methods to control damage with wavelength-dependent temporal spatial pulse shaping, (5) develop simulation models capture the essential physics of these processes. this work will advance understanding pulsed-laser material failure mechanisms limits for a general class materials state art in laser-based processing.

Mission Relevance

By directly addressing stockpile stewardship challenges with cost optimization and utilization of large fusion-class laser systems and by providing guidance for laser system designs with higher ultraviolet output energy or longer wavelengths, this research project supports Livermore's core competency in lasers and optical science and technology. The development of materials for high-average-power systems is relevant to advanced materials and manufacturing and provides new insights into defense-related, directed-energy vulnerabilities. In the long run, this project can provide the foundation for new defense and industrial programs as well as the rationale and impetus for new high-average-power pulsed-laser programs.

FY16 Accomplishments and Results

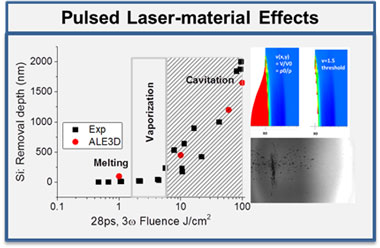

In FY16 we (1) prepared for damage tests (materials, bulk damage limits, fiducials, and fracture-initiation sites) in calcium fluoride, sapphire, and potassium dihydrogen phosphate experiments; (2) set up a laser optically stimulated luminescence table; (3) designed and purchased hardware for portable pump–probe imaging for the system; (4) performed wavelength-dependent, short-pulse ablation experiments; (5) discovered a bulk damage mechanism universal to ion-doped glasses linked to the excited-state, absorption-enhanced Kerr effect; (6) determined that ALE3D, the multiphysics, three-dimensional arbitrary Lagrangian–Eulerian simulation code, was sufficient for pulsed-laser effects in this regime and that HYDRA, a multiphysics hydrodynamics simulation code, was not necessary; (7) developed models for absorption and electronic and ionic thermal diffusivity in silicon; and (8) tested ALE3D equation-of-state models for silicon ablation, performed one-dimensional pulsed-laser ablation simulations, and compared them to measurements (see figure).

Hydrodynamic simulations and high-speed imagery capture the important processes involved in picosecond-pulsed laser ablation in silicon, highlighting for the first time the role of cavitation processes in material removal.