Andrew Pascall (17-FS-007)

Executive Summary

We are exploring the feasibility of using additive-manufacturing techniques to create microscale mechanical-logic gates (the essential components of digital circuits that operate in binary logic). If feasible, the resulting circuitry would have applications to materials that can perform computations without requiring an electrical power source.

Project Description

Though we think of computers as being strictly electronic devices, the original computers were based on mechanical logic, which offers several advantages if it can be readily scaled down to microscale. The main advantage is that mechanical-logic circuits do not require an electrical power source, and computers built from them will have a negligible electromagnetic signature. Recent advancements in additive manufacturing, also called "three-dimensional (3D) printing," enable the precise placement of materials in three dimensions. The Lawrence Livermore National Laboratory's Center for Engineered Materials and Manufacturing recently demonstrated the ability to control the microarchitecture of materials with feature sizes down to 10 micrometers. With these techniques, it may be possible to design mechanical-logic circuits into the microstructure of a material, creating so-called “material logic.” Material logic will allow basic calculations to be performed by the material itself with low electromagnetic signatures and no electrical power input. We intend to demonstrate the feasibility of developing at least one of the universal digital logic gates, either NAND (short for "negative-AND," a type of logic gate that produces an output that is false only if all its inputs are true) or NOR (a logic gate that produces a high output [1] only if all its inputs are low [0]). All other logic gates can be constructed from these two. We also intend to answer the following questions of initial feasibility: (1) Can mechanical-logic gates be designed and additively manufactured? (2) Can the logic gates be arranged into a functioning circuit? (3) Can a logic gate be printed inside the microstructure of an architected material?

The expected result of this study is an operational logic circuit assembled from discrete additively manufactured logic gates. We will attempt to directly print multiple gates into a circuit with no assembly required. A stretch goal is to print a functional material-logic gate at a scale of tens of micrometers, and demonstrate the feasibility of incorporating mechanical logic gates into material microstructures. If successful, this may lead to materials-based computation systems that are difficult to detect, require no external power, and emit no electromagnetic signature.

Mission Relevance

This study supports the NNSA goal to expand and apply our science and technology capabilities to deal with broad national security challenges and is tied directly to the Laboratory's advanced materials and manufacturing core competency.

FY17 Accomplishments and Results

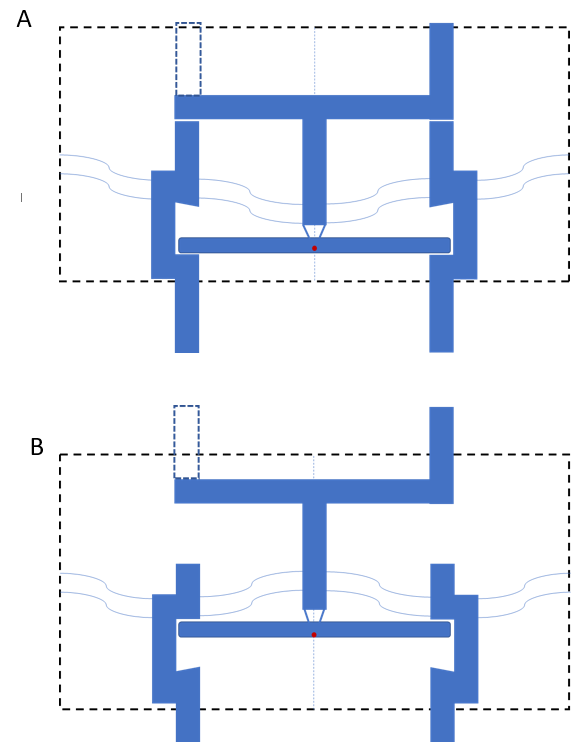

Beginning in May of FY2017, we designed the two mechanical-logic gates, an OR gate and an AND gate (see figure).