Mihail Bora (17-ERD-050)

Executive Summary

We are developing a novel manufacturing design enabled by Livermore's micro-fabrication capability to create total-internal-reflection (TIR) semiconductor photoconductive switches using specially doped diamond substrates. By improving the light utilization in these switches by one order of magnitude, we will remove the major obstacle of poor energy efficiency for widespread adoption of photoconductive switches in power devices.

Project Description

One of the fundamental building blocks of power electronics is the semiconductor switch. Standard semiconductor power switches span a wide range of applications, power levels, and operating frequencies. The limits of the operating frequency are primarily governed by intrinsic material properties such as the speed of electron transport (which limits the maximum operating frequency) and the breakdown electric field strength. Traditionally there has been a trade-off between the speed of electron transport and output power. Optically activated devices have the largest potential for high-power, high-frequency switching because they overcome the major problems of electrically triggered junction devices: jitter (deviation from true periodicity of a periodic signal), slow opening and closing times, low repetition rates, and slow recovery times. Most optically activated devices, however, still rely on charge excitation in the depletion region of the semiconductor junction (~10 µm) and are thus limited in their blocking-voltage capabilities. We plan to improve the light utilization and electrical performance of high-power photoconductive switches. Device operation requires low absorbance coefficients for uniform generation of charge carriers, which results in less than one percent of the incident light being utilized. As a result, a complete 1-MW system needs a large laser light source with a significant penalty in energy efficiency, reliability, size, weight, and power. We are addressing these issues by investigating a new device architecture in which the light is trapped inside the semiconductor material, increasing the effective optical path, and by fabricating devices in diamond, a material with better electronic and thermal properties compared to silicon carbide, the currently used material.

We expect to improve on the performance of 10-MW power semiconductor devices in silicon carbide by enhancing light utilization through TIR trapping, as well as fabricating devices in diamond, a material that promises ultimate performance for photoconductive switching. Higher quantum efficiency will have a significant impact for field deployment of the technology because the photo-excitation light source dominates the size, weight, and power of the system. The potential impact of the technology is illustrated by its capabilities for the three most important parameters for high-power semiconductor devices: voltage, current, and modulation frequency. Existing devices typically perform well in at most two, but not all three areas. We expect our approach to outperform competing technologies by using materials with better electronic properties, and to address the major downside of the photoconductive switch (the low utilization of light) with TIR light trapping. By improving light utilization in photoconductive switches by one order of magnitude, we will remove the major obstacle for widespread adoption of photoconductive switches in power devices, namely poor energy efficiency. Because diamond has the highest known breakdown voltage and thermal conductivity, its use can lead to devices with record operating voltage and current. The frequency of operation for photoconductive switches is actuated optically and is decoupled from the electrical capabilities (voltage and current), potentially enabling devices that are both high power in the gigawatt range and high frequency in the gigahertz range.

Mission Relevance

Our research aligns with Lawrence Livermore National Laboratory's advanced materials and manufacturing core competency through development of a novel manufacturing design enabled by the Laboratory's micro-fabrication capability to create TIR semiconductor photoconductive switches using specially doped diamond substrates. The Laboratory's mission research challenge in directed energy is supported with the technology's potential for use in high radio-frequency power generation at significantly reduced system size and weight, as well as increased power. Furthermore, this research is relevant to the DOE goal to strengthen key science, technology, and engineering capabilities and modernize the national security infrastructure.

FY17 Accomplishments and Results

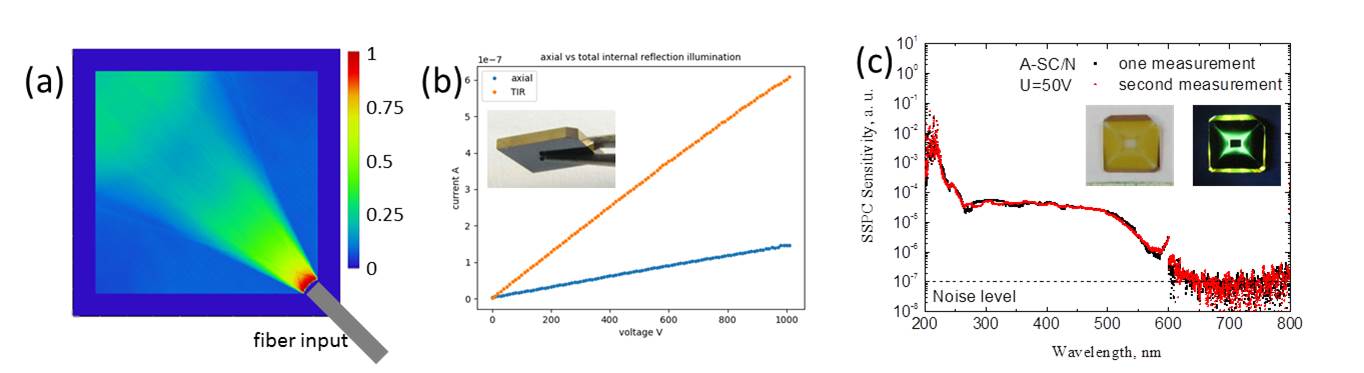

In FY17 we (1) completed numerical simulations for optimization of device architecture and identified key features for improved efficiency of the high-power semiconductor switch, namely illumination from the substrate corner through a curved window; (2) began material characterization to determine optical properties of device components, namely the extinction coefficient of silicon carbide and reflectance coefficient for the silver contacts; (3) conducted experimental testing that showed that the total internal reflection illumination is approximately 15 times more efficient than single-pass axial illumination through the device thickness, in good agreement with the numerical simulation values; and (4) performed additional testing that verified that fabricated devices survive off-state high-voltage testing of 20 kV.