Michael Stadermann (14-ERD-025)

Abstract

Ultrathin, tough, and defect-free polymer films are of interest to a variety of applications such as coating, packaging, separation membranes for desalination or carbon sequestration, masking layers for lithography, and sensor films. They also serve an important function in Inertial Confinement Fusion targets, where they support the fuel target in the center of the hohlraum target capsule. We plan to push the limits of thin-film synthesis and thin-film mechanical properties by producing, characterizing, and modeling freestanding films of atomic-scale thickness with sufficient strength to support macroscale objects. We will study the mechanical properties of ultrathin freestanding polymer films using both experiment and modeling with a special emphasis on yield and failure strain, two properties that remain virtually unstudied. Our research will include a thorough investigation of the effect of fabrication conditions on film properties, and it will link chemical and mechanical properties.

With the successful completion of this project, we expect to produce and characterize the strongest ultrathin freestanding polymer films ever made. We will gain insight into the chemical structures that give rise to this strength, and develop an improved understanding of viscoelastic behavior of polymers, which will potentially transfer into bulk polymer behavior. The results can directly be utilized to produce thinner films for the use in advanced laser fusion targets, where very thin, yet mechanically strong and stretchable films are desirable. Support films have to be as thin as possible to avoid perturbing the implosion, because even films as thin as 45 nm (only about 6 times thicker than a cell membrane) have been shown to have an effect on implosion. We expect to leverage LLNL's freestanding thin-film production capability that produces polyvinyl films for Livermore's National Ignition Facility targets by spin coating or meniscus coating. These films are produced with nanometer uniformity on the wafer scale. Hence, the films are large enough to be tested with methods that directly measure mechanical properties, such as ball indentation or burst pressure tests.

Mission Relevance

Improved understanding of thin-film strength and advanced composite materials that will result from our research supports the Laboratory's advanced materials and manufacturing core competency, and will be useful to guide material selection for target capsule support, which is relevant to ignition-class laser fusion experiments in support of the stockpile stewardship science mission and for inertial fusion science and technology applications.

FY15 Accomplishments and Results

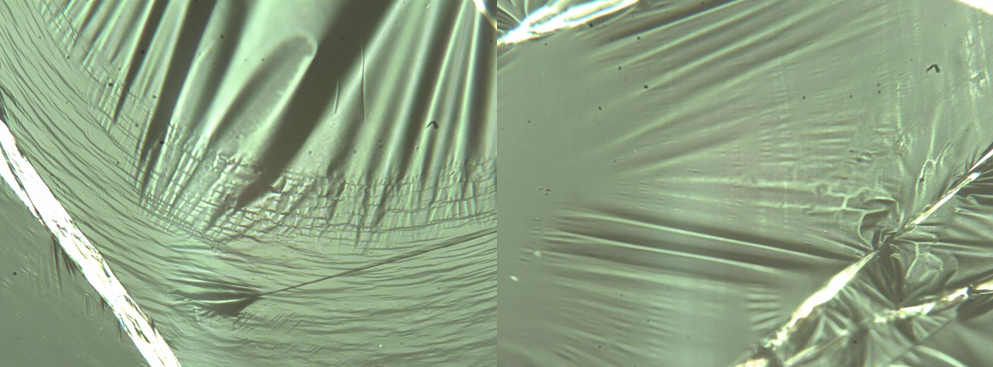

In FY15 we (1) started modifying the thin films by adding softeners and developing an approach to cross-link the polymers; (2) showed that these modifications significantly affect mechanical properties, and helped to identify the failure mechanism that has thus far limited deployment of ultrathin tents on National Ignition Facility targets—if the material yields by cracking instead of shearing, the likelihood of failure is increased (see figure); (3) began to characterize the cracking behavior as a function of environmental conditions during film fabrication and testing; and (4) accompanied these experiments by finite-element modeling, and successfully created a material model that behaves like the experiment and is now used to quantify changes to the material properties and to predict stresses.

Publications and Presentations

- Stadermann, M., “Fabrication of large-area free-standing ultrathin polymer films.” JoVE e52832 (2015). LLNL-JRNL-662583.