Manyalibo J. Matthews (15-ERD-037)

Abstract

During this project we studied the physics and materials science involved in laser materials processing of metals experimentally using custom-built test beds, in situ diagnostics, and simulation. Special attention was given to laser-based powder bed fusion additive manufacturing processes. New light has been shed on the physics of laser materials processing for additive manufacturing such as absorptivity, spatter generation, and microparticle entrainment, all of which can lead to component defects. The experimental and simulation results of this project have proven useful to both internal and external research and development communities for improving additive manufacturing processes.

Background and Research Objectives

Accurate prediction of the material response associated with any laser-based materials-processing technology begins with precise knowledge of the physical mechanisms that are active during the laser–matter interaction. In laser-based powder bed fusion additive manufacturing (LPBFAM) of metal parts, for example, complex hydrodynamics driven by vapor recoil and Marangoni convection lead to rapidly moving liquid–metal interfaces (Matthews et al. 2016) and high cooling rates (Bertoli et al. 2017b) that drive highly nonequilibrium conditions. Changes in absorptivity (Boley et al. 2016) due to melt-pool motion can lead to fluctuations in energy coupling (Trapp et al. 2017) that drive excursions in melt-track morphology (Bertoli et al. 2017a), microstructure, and residual stress. Under certain circumstances, vapor recoil can lead to laser-keyhole formation during laser powder bed fusion processing, which in turn can lead to part pore defects which adversely affect mechanical properties (Wang et al. Forthcoming). Furthermore, ejection of material from the melt pool and entrainment of powder from melt-vapor flux can generate spatter particles (Matthews 2017) that become incorporated into subsequent powder layers and can lead to lack-of-fusion defects. Attempts have been made to clarify the complex physics involved using hydrodynamic simulations that have proven useful but ultimately require experimental tools with sufficient energy, spatial, and temporal resolution (Matthews et al. 2016; Bertoli et al. 2017a & 2017b; Boley et al. 2016; Chapman et al. 2016).

For this project, we developed experimental test fixtures and platforms with high-speed optical and thermal imaging capabilities that were used to study the physics of laser-based materials processing associated with additive manufacturing (Matthews et al. 2016; Bertoli et al. 2017a & 2017b; Ly et al. 2017; Chapman et al. 2016), surface nanocoarsening (Chapman et al. 2016), and laser-assisted friction stir welding (Wiechec et al. 2017; Wu et al. Forthcoming). Hydrodynamic finite-element modeling of the powder bed was used to simulate the melt-pool morphology and dynamics, providing insight into energy coupling, laser-keyholing, and spatter-generation mechanisms. The simulations conducted and results obtained during this project offer new insights into mission-relevant processing technologies such as LPBFAM, which can be exploited to control material properties (Roehling et al. 2017) and develop new additive manufacturing (AM) methods (Matthews et al. 2017; Tapia et al. 2017).

The goal of this project was to expand the scientific foundation and understanding relevant to an emerging class of laser-assisted manufacturing processes through physics experiments that can be compared with predictive computational modeling and simulation. We focused our studies on LPBFAM (also known as selective laser melting), by far the most prevalent process for direct metal fabrication. In addition, development of optical diagnostics for high-resolution process monitoring and real-time feedback (such as light scattering, interferometry, and thermography) can enable adjustment of laser parameters such as laser power, and spot size and shape to enhance material properties. To accomplish our project goal, we established the following objectives.

- Develop methods to measure powder absorptivity in situ and at high temperature.

- Develop optical and thermal diagnostics as required to improve both our understanding of the physics in play and in situ process control.

- Study metal-alloy melting and flow with high spatial and temporal resolution to clarify the roles of various physical processes.

- Explore methods to adjust laser beam parameters during material deposition.

- Identify improvements in material processing and for manufacturing machine design.

Scientific Approach and Accomplishments

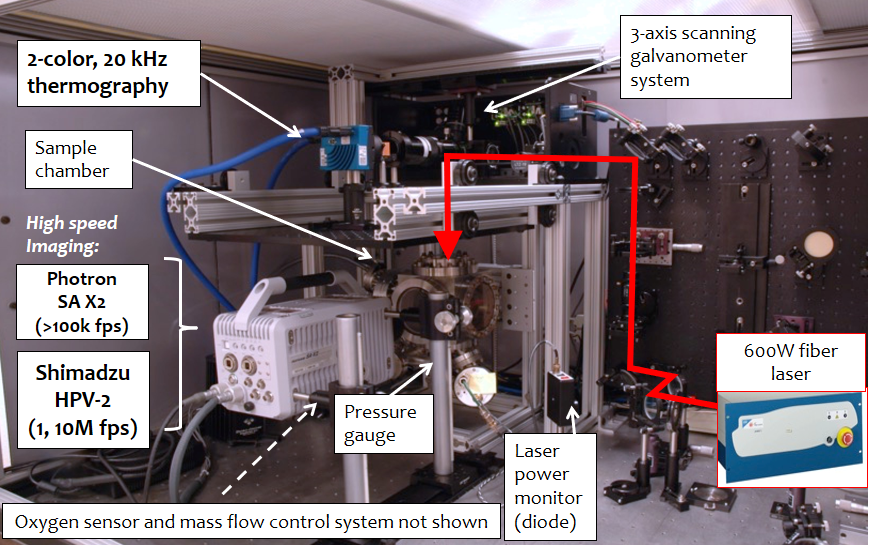

Prior to our work in this area, no one had designed and executed experiments at the relevant time and spatial scales needed to fully understand the laser–matter interactions involved in laser-based materials processing of metals. Furthermore, the capabilities we developed in our laser and AM laboratories have enabled us to study other processes such as laser-induced coarsening of thin nanoporous films and 5-kW diode laser heating for laser-assisted friction stir welding (LAFSW). The primary experimental setup used for our LPBFAM studies (Figure 1) was a 600-W fiber laser directed through a three-axis galvanometer scanner and into a vacuum chamber through a high-purity fused silica window. The vacuum chamber is evacuated using a turbomolecular pump and purged with argon. A separate setup was used outside the chamber for both LPBFAM and LAFSW studies that included localized flow of argon gas to minimize oxidation. Surface-coarsening experiments on thin films of nanoporous gold were performed using either a 5-W, 532-nm continuous wave (CW) laser at Lawrence Livermore National Laboratory or a 50-mJ, 532-nm, 7-ns pulsed-laser system at the University of California (UC), Davis. Depending on the frame rate and field of view needed, various high-speed cameras were used (Mikrotron EoSens, Shimadzu HPV-2, or Photron SA2X) and sometimes included microscope optics for high-resolution imaging. Imaging was performed at up to 10 million frames per second, with an optical resolution of approximately 5 μm. For LPBFAM, approximately 30-μm metal powders (steel 316L, Ti64, tungsten, AlSi10Mg, and Inconel 625) were manually applied using a stainless-steel razor edge to simulate the spreading process in a production machine. A limited number of experiments were also conducted on an LPBFAM printing machine developed by the Fraunhofer Institute. Additional details on experimental methods used can be found in Matthews et al (2016) and Chapman et al (2016).

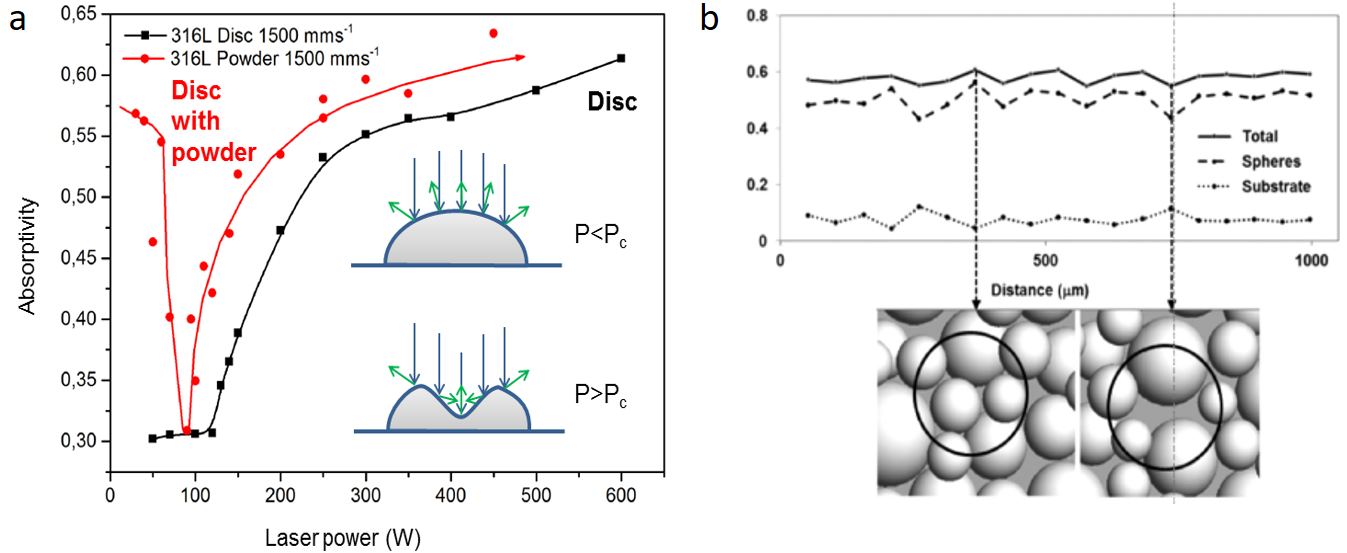

Every materials processing run begins by coupling of laser energy to a work piece. Therefore, it is critical that the laser absorptivity and details of the laser–matter interaction are thoroughly characterized. A custom fixture for measuring absorptivity was developed for this purpose (Boley et al. 2016; Trapp et al. 2017). The effective optical absorptivity of tungsten, aluminum, and steel discs as a function of laser power (30–600 W) and scan speed (100, 500, and 1,500 mm/s) was measured using microcalorimetry. These measurements may have been the first of their kind for LPBFAM and laser microwelding. The absorptivity of steel-powder layers as a function of laser power was also measured at a scan speed of 1,500 mm/s (Figure 2a). Low-power results closely agreed with literature values of solid or liquid-metal-absorptivity measurements. However, at high power levels, the onset of a vapor recoil keyhole depression causes a sharp increase in the effective optical absorptivity, which eventually saturates to values in the range 0.6–0.8 for all materials (Figure 2a). In the case of metal powder (steel 316L), an additional transition from powder absorptivity values close to those calculated using ray tracing (Figure 2b) to liquid and then to keyhole exemplifies the very strong laser power dependence of energy coupling associated with LPBFAM and may explain why a manufactured part's quality is dependent upon laser parameters.

It is worth noting that highly nonlinear energy-absorption behavior can help to understand scaling behavior in LPBFAM. It is customary to normalize melt-pool depths, for example, using a volumetric energy density. However, our work indicates that this scaling fails at certain laser powers and scan speeds (Bertoli et al. 2017a), which can be explained by an assumed constant absorptivity. More flexible scaling laws based on Gaussian processes were explored in collaboration to enable more accurate melt-pool depth predictions (Tapia et al. 2017).

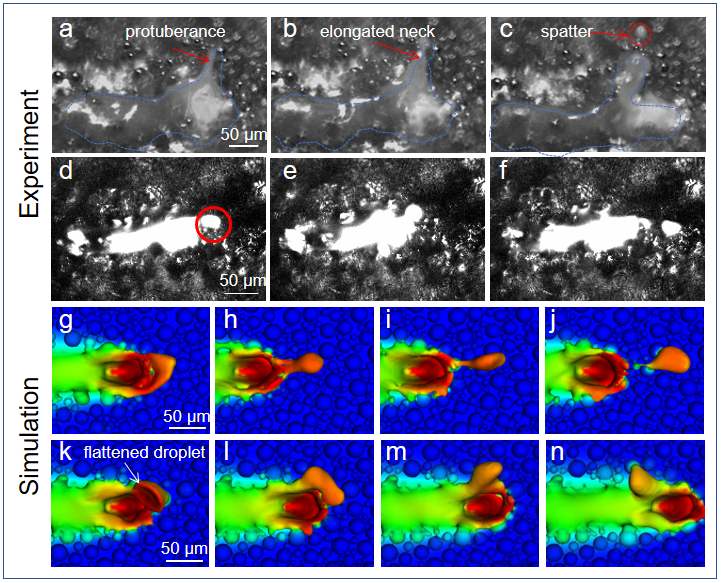

Next, we sought to characterize the material response under laser illumination of metal plates, powders, and films. Our work described the underlying laser–matter interaction mechanisms in LPBFAM leading to spatter, powder denudation, and melt-pool formation (Matthews et al. 2016; Ly et al. 2017). In addition to a long-standing misconception that the laser interacts directly with the powder (it does not, but rather interacts with a melt pool that in turn interacts primarily with the powder), our results showed that powder displacement occurs due to a Bernoulli effect caused by metal-vapor flow and not by thermal expansion, as previously believed for over a decade. In fact, the metal-vapor flow, which also drives recoil and a surface depression with potential to cause pore defects below the surface, is essentially at the heart of the LPBFAM laser–matter interaction. Figure 3 shows both experiment and simulation results of laser scanning through a metal-powder layer, each properly resolved at microsecond and micrometer scales.

In Figure 3 images a through c, the illumination laser is turned on and the powder in the background is visible. A protuberance forms at the rim of the depression in image a, the elongated neck thins out in image b, and a spherical droplet is ejected in image c, similar to the ejection behavior from a bare plate. The presence of powder hinders the forward flow motion since the recoil momentum has a small component along the beam-scanning direction (with a pressure of approximately 7.5 kPa, close to boiling), leading to a buildup of liquid molten material ahead of the laser beam. Figure 3 images d through f show a large, 30-μm spherical droplet ejected in front of the melt pool with a velocity of approximately 5 m/s. For the simulation (ALE3D) in Figure 3 image g, the droplet forms at the rim of the depression with vapor recoil forces pushing the molten droplet forward. The droplet size increases in Figure 3 images h and i as its volume grows due to the addition of cooler liquid from recently melted powder. In Figure 3 image j, the spatter has already acquired enough forward momentum that it escapes and lands a short distance ahead.

Throughout both experiments and simulations, we observe subthreshold ejection events where protrusions from the melt pool do not completely eject and are instead absorbed back into the melt pool. The action of the recoil vapor pressure of the liquid is evident as the laser causes heating to boiling temperatures with peak simulated temperatures above 3,000 K. The radial pressure violently flattens one side of the droplet relative to the laser spot center, as indicated by the arrow in Figure 3k. The nascent droplet is entrained by the strong rotational melt flow in images l and m, and it is swept toward the back where it merges into the melt pool in image n. Spatter can still escape in the backward direction if the kinetic energy is greater than the surface tension. Together, these experimental and simulation results (Wang et al. Forthcoming) shed light on the mechanism for droplet ejections (known as spatter) which can lead to build defects if droplets fall back to the build surface and are large enough to prevent incomplete fusion, for example. Similarly, experiments and simulations studying powder denudation (Matthews et al. 2016) and melt-track cooling rates (Bertoli et al. 2017b) have significantly contributed to new understanding of LPBFAM.

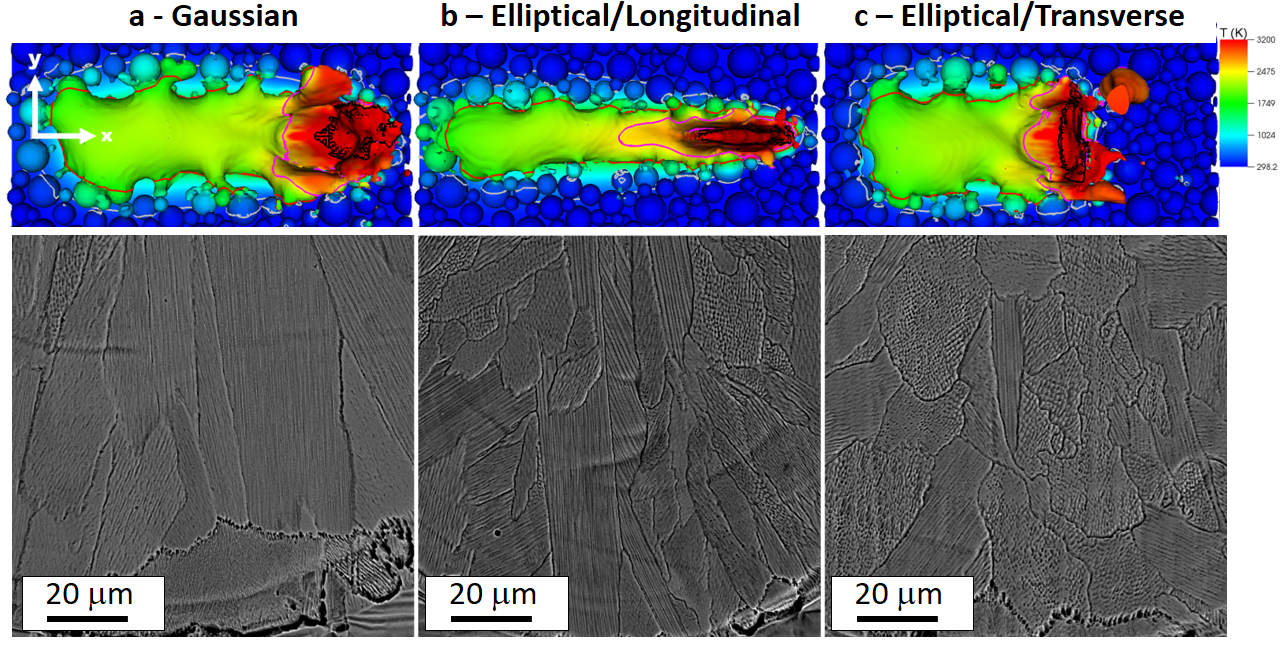

With a better understanding of laser-energy coupling and melt-pool dynamics, material response can be studied with a much firmer foundation. When considering the mechanical performance of an additively manufactured metal part, control of the microstructure is crucial. As is well-known from the casting literature, control of melt-front velocities and thermal gradients can be used to dial in the desired microstructure for a given metal alloy. However, under the very high (approximately 106 K/s) cooling rates (Bertoli et al. 2017b) typical of LPBFAM, such control is not always easy to attain. Generally, a fine-scale, roughly symmetrical (or equiaxed) grain structure is desirable in terms of final mechanical properties. However, the rapid solidification often leads to columnar grains, with long axes aligning along the build direction. Figure 4a shows such a columnar microstructure in steel 316L, using a typical Gaussian-shaped laser beam, ubiquitous in LPBFAM systems. Our initial hypothesis was that, by adding steep laser beam gradients using elliptical beams, cooling rates could be driven yet higher and drive equiaxed nucleation.

The effects of beam shape on thermal gradients and morphology were investigated using our experimental apparatus (Figure 1) followed by metallography and using ALE3D finite-element simulations (Figure 4). From the track-melting simulations, the role of surface tension and vapor recoil on track topography can be observed (Figure 4, top row). Using Figure 4 simulation graphs, the lateral temperature gradient can be judged by using the distance between the red and gray isothermal contours, where the red contour is approximately the melting temperature of 316L steel (~1,700 K) and gray is 500 K. Considering the distance between the front of the topological depression and the 1,700 K (red) isothermal contour in the tail region, the temperature gradient is steepest in the scanning direction using the transverse elliptical profile (68 × 103 K/cm), followed by the Gaussian (50 × 103 K/cm) and longitudinal elliptical (47 × 103 K/cm) profiles. This is related to the intensity distributions produced by the different beam profiles relative to the scan direction: the centerline of tracks melted by the Gaussian and longitudinal elliptical profiles experience heating longer than those melted by the transverse elliptical profile.

Surprisingly, the microstructures revealed from cross-sectioning melt tracks, etching, and imaging (Figure 4, bottom row) show that both elliptical beams produced more equiaxed behavior than Gaussian, despite the differences in predicted cooling rates. We discovered that the internal melt-flow velocities seemed to play a bigger role than simply thermal gradient. The maximum melt-flow velocity was simulated to be lower in magnitude using the Gaussian profile (1.1 × 10–3 cm/s) than using either the transverse elliptical (1.3 × 10–3 cm/s) and longitudinal elliptical (2.2 × 10–3 cm/s) profiles. Examining the topological depression caused by vapor recoil, the transverse elliptical profile produced backward melt flow at the greatest velocity, with horizontal flow from the bottom of the topological depression and upward melt flow near the surface of the tailing wall of the depression. The longitudinal elliptical profile produced backward melt flow at a lower velocity, although the flow was directed downward in the depression. Our hypothesis is that dendrite-tip breaking caused by rapid fluid flow during early heterogeneous nucleation is the root cause for finer grain structure in the elliptical beam samples.

Most interestingly, the parameter space over which equiaxed or mixed equiaxed–columnar microstructures are produced is much larger for the elliptical beam profiles than for the circular beam profiles, with the transverse elliptical profile being most encouraging for equiaxed solidification (Figure 4c). That is, not only can finer equiaxed structures be obtained through beam shaping, our work has shown that a broader, more stable processing space can potentially also be achieved. New methods for additive manufacturing can now be contemplated based on the local beam shaping (presented in this report) or wide area beam shaping using distributed laser diodes (Matthews et al. 2017), which was demonstrated under a collaboration between our project and LDRD project 14-SI-004, “Deterministic Multifunctional Materials and Manufacturing Initiative.”

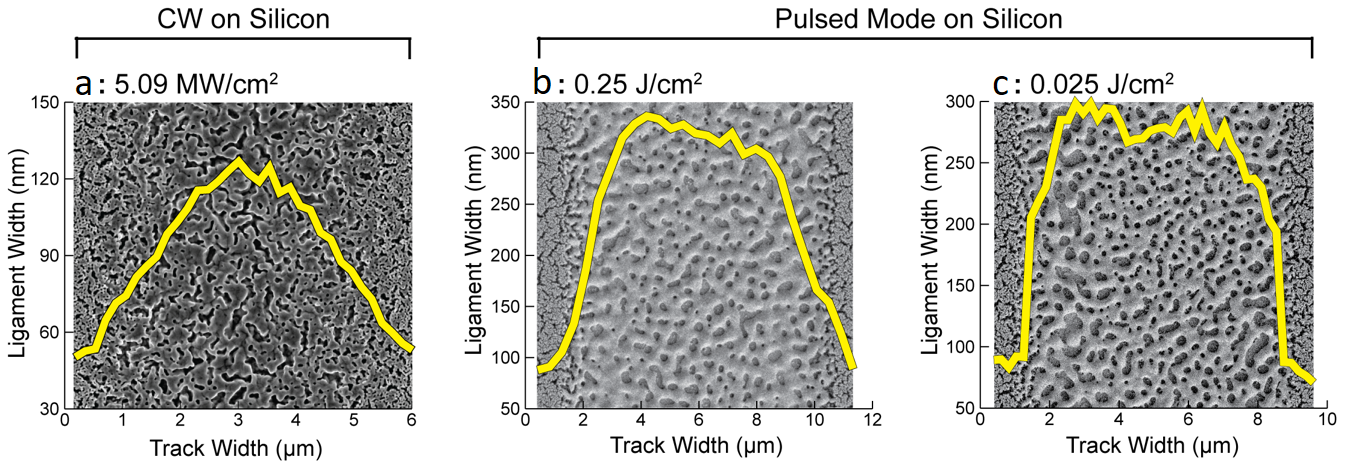

Lastly, we extended our experimental and modeling techniques to a better understanding of laser processing of metals for applications outside of LPBFAM. A novel laser materials-processing approach was explored to control and observe surface coarsening of nanoporous gold (np-Au) films for neural electrode applications (Chapman et al. 2016b). Guided by simulation results, np-Au thin films were fabricated on both silicon and glass supporting substrates. These samples were then annealed by either CW or pulsed-mode laser irradiation using custom set-ups. Real-time measurement of morphology evolution was achieved using a custom-built speckle auto-correlation spectrometer (Chapman et al. 2016a). The resulting np-Au morphologies, studied by scanning electron microscopy (SEM), differ significantly for the different annealing parameters, most notably between CW and pulsed-mode annealing (Figure 5). Large changes in the coarsening distributions (superimposed on SEMs) are seen in pulsed mode compared to the CW mode (Figure 5). Interestingly, the lower pulsed energy density used in the simulations (0.025 J/cm2) also led to complete melting of the np-Au film contrary to the simulation that predicted film temperatures well below the melting temperature of Au. This can be explained by the power range of the pulsed-laser system used for this study and the limited thermal diffusion length through the films. To achieve appreciable surface diffusion mediated coarsening of np-Au with a pulsed-mode laser would require combining very high pulse-repetition rates with extremely low power density, which essentially converges the pulsed mode to CW mode. Thus, our work helped to clarify the operating regimes of pulsed versus CW for laser processing of np-Au films.

In our work focused on large-scale (mm to cm) laser materials processing, our goal was to use a modified version of our setup in Figure 1 to evaluate the efficacy of using low-cost laser diodes for pre- or post-heating HY-80 steel during friction stir welding. Specifically, we explored both polarization and beam-size effects in heating HY-80 plates using thermocouples and IR imaging (Wiechec et al. 2017).

Impact on Mission

Our project addressed Lawrence Livermore National Laboratory's strategic need for more agile and responsive material development and manufacturing techniques. The resulting validation of hydrodynamics code models will advance laser-assisted additive manufacturing as an integral part of the Laboratory’s advanced materials and manufacturing core competency. Several of the Laboratory’s capabilities, including lasers and optical materials, high-performance computing, and materials and advanced manufacturing, were combined during this project to explore the fundamental materials science and physics of laser-based surface processing of complex morphologies, thus supporting the Laboratory's advanced materials and manufacturing core competency. Special attention was given to LPBFAM processes, a technology critically important to the Laboratory’s stockpile stewardship program.

Conclusion

The experimental and simulation results of our project have elucidated the physics of laser materials processing for additive manufacturing, including absorptivity, spatter generation, and the role of micro-particle entrainment. Simulations of melt-pool motion and ejections agree well with high speed video used as part of a custom test bed developed for this project. However, we have discovered a more dominant process related to metal-vapor-driven particle entrainment that leads to powder material redistribution and which reveals new physics not yet contained in current models. The results presented here have stimulated further development of new multi-phase flow models to address the detailed physics of laser-vapor-driven particle entrainment to better understand process conditions that can lead to LPBFAM component defects.

This project has also spawned or inspired the following new research projects in which several of our project members are currently participating:

- In situ x-ray characterization of LPBFAM (in collaboration the SLAC National Accelerator Laboratory and NASA's Ames Research Center)

- Physics of multi-laser beam LPBFAM (sponsored by the Air Force Research Laboratory)

- Defect signatures and diagnostics development (sponsored by NNSA)

- Experimental validation effort within Livermore's Exascale Computing Project (sponsored by DOE).

References

Bertoli, U. S., et al. 2017a. "On the Limitations of Volumetric Energy Density as a Design Parameter for Selective Laser Melting." Materials & Design 113:331–340.

——— 2017b. "In-situ Characterization of Laser-Powder Interaction and Cooling Rates Through High-Speed Imaging of Powder Bed Fusion Additive Manufacturing." Materials & Design 135:385–396. doi: 10.1016/j.matdes.2017.09.044.

Boley, C. D., et al. 2016. "Metal Powder Absorptivity: Modeling and Experiment." Applied Optics 55(23):6496–6500. doi: 10.1364/AO.55.006496.

Chapman, C. A. R., et al. 2016a. "Utilizing Dynamic Laser Speckle to Probe Nanoscale Morphology Evolution in Nanoporous Gold Thin Films." Optics Express 24(5): 5323–5333. doi: 10.1364/OE.24.005323.

——— 2016b. "Engineering On-Chip Nanoporous Gold Material Libraries Via Precision Photothermal Treatment." Nanoscale 8:785–795. doi: 10.1039/C5NR04580K.

Matthews, M. J. 2017. "Metal Vapor Micro-Jet Controls Material Redistribution in Laser Powder Bed Fusion Additive Manufacturing." Scientific Reports 7 (4085). doi: 10.1038/s41598-017-04237-z.

Matthews, M. J., et al. 2016. "Denudation of Metal Powder Layers in Laser Powder Bed Fusion Processes." Acta Materialia 114:33–42. doi: 10.1016/j.actamat.2016.05.017.

——— 2017. "Diode-Based Additive Manufacturing of Metals Using an Optically-Addressable Light Valve." Optics Express 25(10):11788–11800. doi: 10.1364/OE.25.011788.

Roehling, T. T. et al. 2017. "Modulating Laser Intensity Profile Ellipticity for Microstructural Control During Metal Additive Manufacturing." Acta Materialia 128:197–206. doi: 10.1016/j.actamat.2017.02.025.

Tapia, G., et al. 2017. "Gaussian Process-Based Surrogate Modeling Framework for Process Planning in Laser Powder-Bed Fusion Additive Manufacturing of 316L Stainless Steel." The International Journal of Advanced Manufacturing Technology, doi: 10.1007/s00170-017-1045-z.

Wang, Y., et al. Forthcoming. "Additively Manufactured Stainless Steel with High Strength and Ductility." Nature Materials.

Weichec, M., et al. 2017. "Analysis of High-Power Diode Laser Heating Effects on HY-80 Steel for Laser Assisted Friction Stir Welding Applications." World Journal of Engineering and Technology 5:97–112.

Wu, S. S., et al. Forthcoming. " Polarization Effects Associated with Thermal Processing of HY-80 Structural Steel Using High Power Laser Diode Arrays." Optical Engineering.

Presentations and Publications

Calta, N., et al. 2017. “High Speed Thermal Imaging of the Melt Pool During Laser Powder Bed Fusion of Metal Alloys.” Presentation at the Solid Freeform Fabrication Symposium, Austin, TX, August 7–9, 2017. LLNL-PRES-736354.

Giera, B., et al. 2017. “Machine Learning Based Monitoring of Advanced Manufacturing.” Presentation at the Solid Freeform Fabrication Symposium, Austin, TX, August 7–9. 2017. LLNL-PRES-736249.

Guss, G., et al. 2017. “Review of Ultra-High-Speed Imaging of Powder Bed Fusion Additive Manufacturing Processes.” Presentation at the Solid Freeform Fabrication Symposium, Austin, TX, August 7–9, 2017. LLNL-736617.

Matthews, M., et al. 2016a. “In situ Monitoring of Metal Additive Manufacturing with Infrared Thermography.” Invited Presentation at the Advanced Prototype Engineering Technology Symposium, Lexington, MA, November 8–9, 2016. LLNL-PRES-707262.

——— 2016b. “In situ Monitoring of Metal Additive Manufacturing with Infrared Thermography.” Invited Presentation at the In-situ X-ray Characterization During Selective Laser Melting Workshop, Golden, CO, October 4, 2016. LLNL-PRES-707262.

Trapp, J., et al. 2017. “Direct Measurements of Laser Absorptivity During Metal Melt Pool Formation Associated with Powder Bed Fusion Additive Manufacturing (AM) Processes.” Presentation at Photonics West in San Francisco, CA January 28–February 2, 2107. LLNL-PRES-719992.

Wu, S. S., et al. 2017. "Laser Beam Ellipticity and Microstructural Control in Metal Additive Manufacturing." Presentation at Conference on Lasers and Electro-Optics, San Jose, California, May 14–19, 2017. LLNL-PRES-731427.