Mark Converse (14-ERD-064)

Abstract

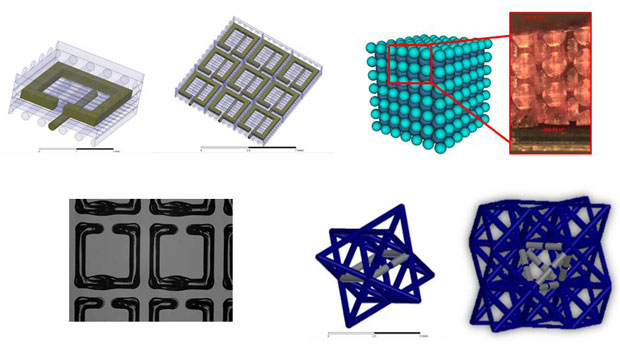

We can create artificial materials with properties not found in nature whose material performance is based on tightly coupled electromagnetic and mechanical microstructures. For electromagnetic materials, properties could include negative values of permittivity, permeability, or index of refraction. Mechanical properties of interest include low density, high stiffness, fracture strength versus stiffness, or even a specified stress-versus-strain curve. Our objective is to create one such material class, so-called "multifunctional metamaterials," by combining electromagnetic and mechanical properties in novel ways that have interesting electromagnetic properties in the low gigahertz-frequency spectrum. The metamaterial will be optimized for negative index of refraction and low loss over a broad bandwidth, as well as high stiffness and low weight. A negative index metamaterial causes light to refract, or bend differently than in more-common positive refractive index materials. We will accomplish our objective by combining theory, design by computational simulation and numerical optimization, and the Laboratory's additive manufacturing expertise and capabilities. This coupling of functionality has never been done before with additive manufacturing. Such capability will greatly expand the potential of user-specified multifunctional materials.

If successful, we will have created a new material class of electromagnetic and mechanical, negative-index-of-refraction multifunctional metamaterials. Such class of materials will be the first three-dimensional isotropic negative-index materials in the microwave regime. This research could affect radar and communications system design, device miniaturization, advanced sensor design, and the practical realization of many negative-index devices that are currently just a theoretical or laboratory-based novelty. Examples of benefits are the potential for microwave invisibility, advanced antenna design with a significantly greater range of achievable sizes and form factors, and large lightweight components, such as 10-ft microwave lenses that weigh just a few pounds. This technology could also enable sensors in which stress and strain response is coupled to the electromagnetic response to maximize sensitivity or accuracy.

Mission Relevance

This research is important for the Laboratory's cyber security, space, and intelligence strategic focus area. It could lead to smaller microwave radar and communication components and systems, advanced microwave sensors, and greater design capabilities for any type of microwave system with user-specified materials. Creating a new class of metamaterials is also well aligned with Livermore's core competency in advanced materials and manufacturing.

FY15 Accomplishments and Results

In FY15 we (1) achieved progress toward a viable solution to print the one-dimensional metamaterial after encountering a number of unexpected difficulties with conductive ink printing, (2) made initial measurements on the ink with our conductivity measurement protocol, (3) determined that we cannot make a three-dimensional isotropic metamaterial consisting of split-ring resonator and dipoles impressed on the octet substrate because of limitations with the two-material projection micro-stereolithography printer yields, and (4) demonstrated, with simulation, a re-imagined solution consisting of one material. The material is a high-dielectric ceramic that can be constructed using the large-scale projection micro-stereolithography printer, consisting of tightly packed spheres of two different sizes, and which should provide a material with both negative permeability and permittivity within a narrow frequency band.